Last month, we reported the impending launch of E3D’s highly anticipated-yet-delayed Revo ObXidian nozzle. Now, a new, in-depth blog post from E3D details its features and properties – and announces the opening of preorders, with an estimated mid-November ship date.

“Unlike other abrasion-resistant Nozzles,” E3D writes, “ObXidian’s copper alloy construction has a similar thermal performance to brass, making it a true drop-in replacement.”

This means users will not need to tweak temperature values. Instead, they’ll simply select the profiles they use for brass nozzles and start printing.

The nozzle’s non-stick coating helps plastic accumulations drop off before they become too unwieldy. By continuously depositing built-up filament, ObXidian greatly reduces the chances of print artifacts and blobs of discolored filament. The coating also results in a nozzle that is much easier to clean than standard brass nozzles.

Pre-orders for 0.4 mm and 0.6 mm versions of the ObXidian nozzle are now open. The expected ship date is the week of November 14. According to E3D, 0.25 mm and 0.8 mm versions are coming soon. You can read the full version of E3D’s blog here.

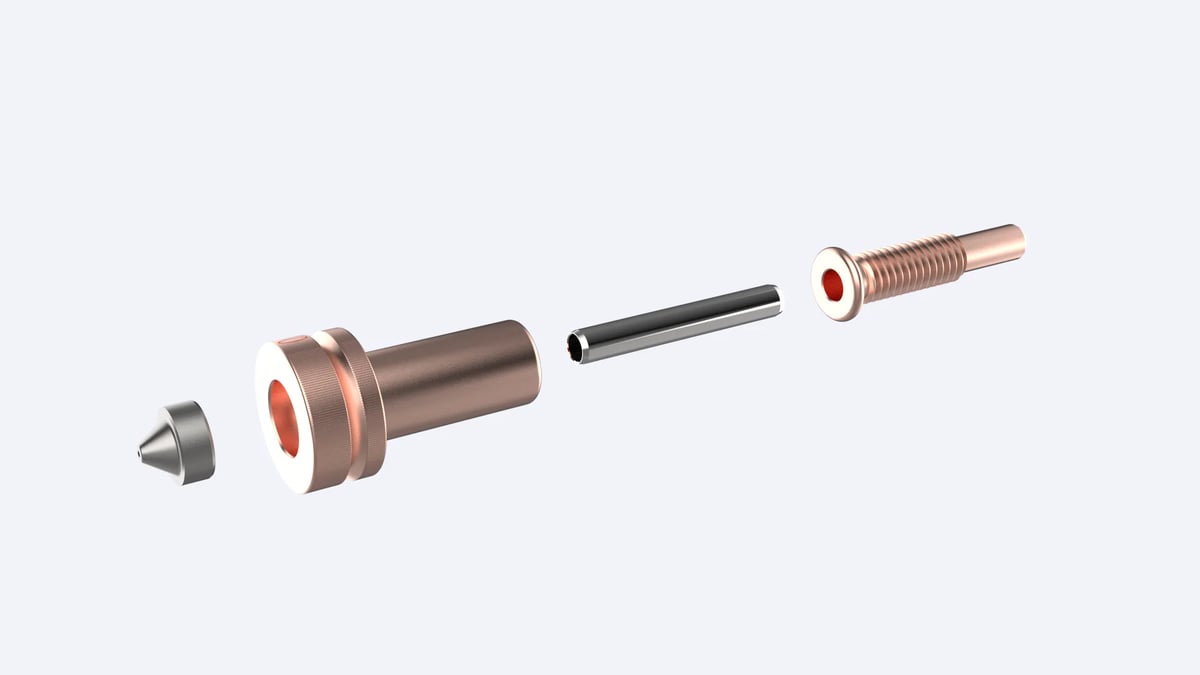

Lead image source: E3D

License: The text of "E3D’s ObXidian Nozzle Is Now Available for Preorder" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.