There are several benefits that resin 3D printers offer over the traditional extrusion-based FDM process, the most notable of which is print quality. A growing number of desktop-sized resin machines have given hobbyists and professionals the ability to print objects with flawless resolution.

That said, there are still certain aspects that hinder widespread adoption of resin-based 3D printers. One thorn in the side of this 3D printing technology is the final step: post-processing.

The need to remove prints manually and cure them under UV light can be a nuisance for the end-user, especially those who are inexperienced. Many desktop SLA and DLP machines don’t include an all-inclusive post-processing solution, and this can create a mess or other unwanted issues.

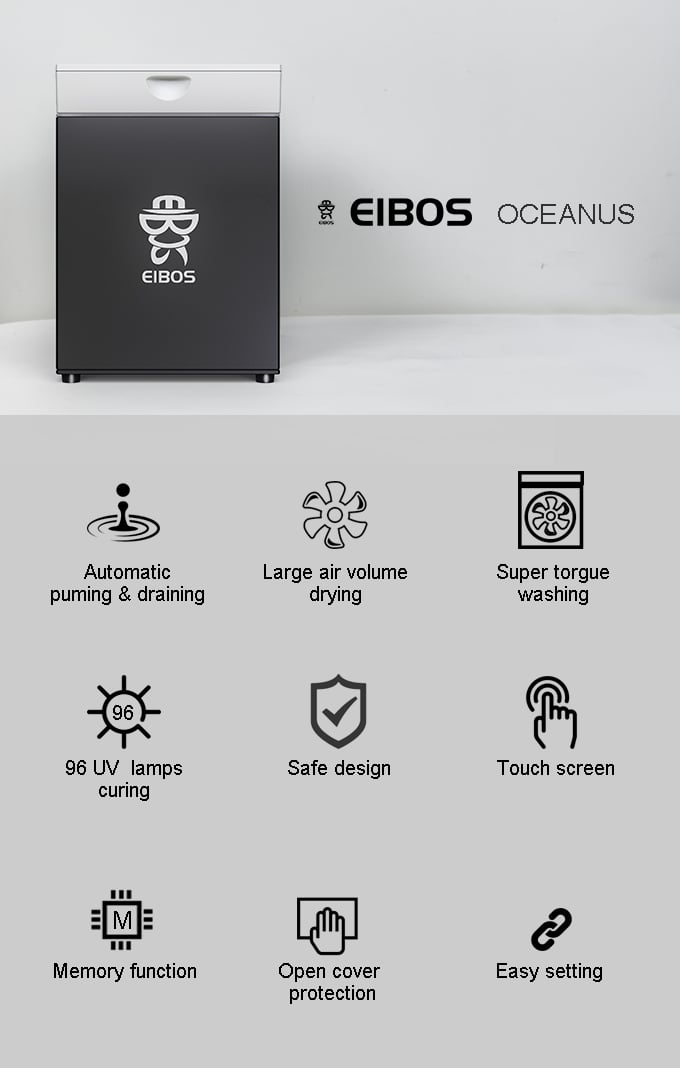

The EIBOS Oceanus, now available on Kickstarter, is an all-in-one resin 3D printing post-processing system that is fully automated. Aiming to solve the issue of messy and time-consuming post-processing, the Oceanus packages resin 3D printing technology in the form of a general home appliance.

Operationally akin to a laundry machine, this post-processing system streamlines the final step of the resin 3D printing process.

How exactly does the EIBOS Oceanus manage to reinvent resin 3D printing post-processing? Let’s take a look at how this automated system works.

EIBOS Oceanus: Easy to Use and Fully Automated Post-Processing System

The primary purpose of EIBOS Oceanus is to remove the manual labor that comes with finishing resin 3D printed parts. Not only is manual post-processing time-consuming, it’s also messy, requires extra caution, and can also expose users to unwanted odors from resin. With Oceanus, the entire process is automated.

Set up like a washing machine, this hardware configuration includes two valves, a water inlet and drain outlet. Using two pipes that come with the Oceanus, the machine is connected to a bottle equipped with a cleaning liquid. The manufacturer recommends utilizing a 4L transparent bottle so that the capacity of the cleaning solution can be monitored.

The user interface is set up to be easy to understand and operate. The top panel includes six different buttons: including an On/Off switch, water level selection (L, M, H), wash, dry, cure settings, as well as a start/stop function. Users can run the wash, dry, and cure settings independently of one another or in combination.

Featuring a “core computer,” EIBOS Oceanus is able to handle the five primary functions that are required for finishing resin 3D printed parts, including pumping, draining, cleaning, air-drying, and curing. By handling each of these steps inside of the chamber, users rarely have to come in contact with resin.

The cleaning process is controlled by a powerful built-in motor that spreads a cleaning solution across the entire model, not missing a single section or causing any damage. There is no direct contact or brush used to clean the model, which adds protection to the surface of the 3D printed part.

A giant enclosed displacement fan is used to air-dry 3D printed models. The internal circulation helps prevent diffusion of cleaning liquid, eliminating unpleasant odors from the external environment. For curing, the Oceanus contains 96 UVA lamp beads that are spread across the four walls in the machine’s chamber. This even spread of UV light enables the 3D printed part to be cured more effectively and in a shorter span of time.

Finally, another major benefit of EIBOS Oceanus is the control given to the end-user. The ability to select each function independently or combine them into one process makes this automated machine ideal for any resin 3D printing owner. Moreover, users can select different durations or create their own process to curate how your 3D printed part is finished.

All in all, EIBOS Oceanus is striving to solve one of the biggest issues that comes with resin 3D printing: the inefficient and oftentimes daunting post-processing step. With this machine, the manufacturer hopes to bring more clarity, cleanliness, and convenience to the end-user, allowing for more time to explore their creativity.

During the Kickstarter campaign, crowdfunders can access an early bird price of $109.99 (plus shipping).

Want to learn more about the EIBOS Oceanus? Visit the Kickstarter campaign here.