In a world that’s rapidly digitizing, 3D printing has emerged as a revolutionary technology, transforming everything from manufacturing and construction to medicine and art. Its ability to convert digital models into tangible objects has opened unlimited possibilities, enabling creators and innovators to breathe life into their most ambitious concepts.

For over 10 years, Shenzhen Mingda Technology Co., Ltd has been a leading manufacturer of professional large industrial 3D printer in China. The company has made a name for itself by focusing on building high-quality and reliable 3D printers, along with comprehensive support and service to the customers all over the world.

The MINGDA MD-400D 3D printer is one of the latest machines to join the growing landscape, claiming to further push the boundaries of this technology with its host of unique features and capabilities. At the heart of these features lies the Independent Dual Extruder (IDEX) system, a step up from the conventional single extruder found in most 3D printers.

As opposed to a single extruder that prints one color or material at a time, IDEX enables two independent extruders to operate simultaneously, creating an opportunity for multi-material and multi-color printing in a single run. The capabilities of the MD-400D’s IDEX system go beyond just this basic functionality and into advanced materials.

Let’s learn more about the MD-400D 3D printer and its professional features.

MINGDA MD-400D 3D Printer: Advanced Extrusion Within a Professional-Grade Frame

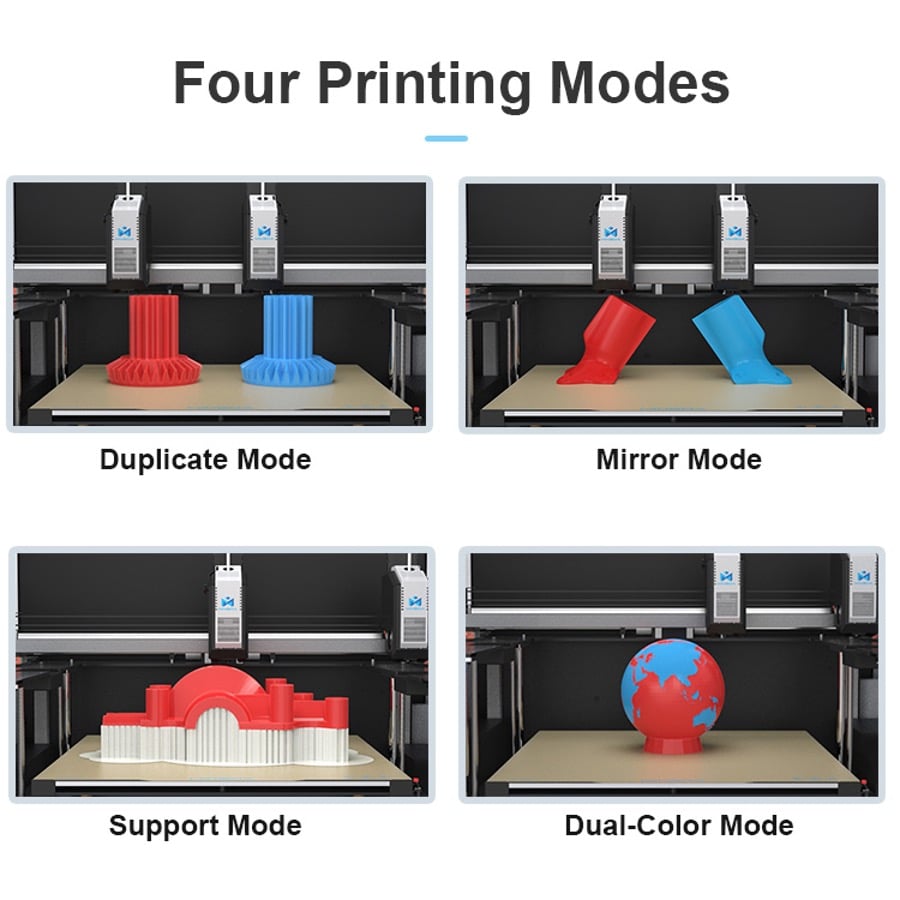

First and foremost, the MD-400D is engineered with an Independent Dual Extruder (IDEX), making it stand out in its class. It offers several different printing modes that make it both versatile and capable of tackling numerous projects.

The Duplicate Mode offers the capability to print two identical models at once, thus increasing productivity. Mirror Mode presents a unique opportunity for users to create symmetrical models while saving significant time. Dual-Color Mode provides an option to print a single model in two colors, adding an artistic edge to the printing process.

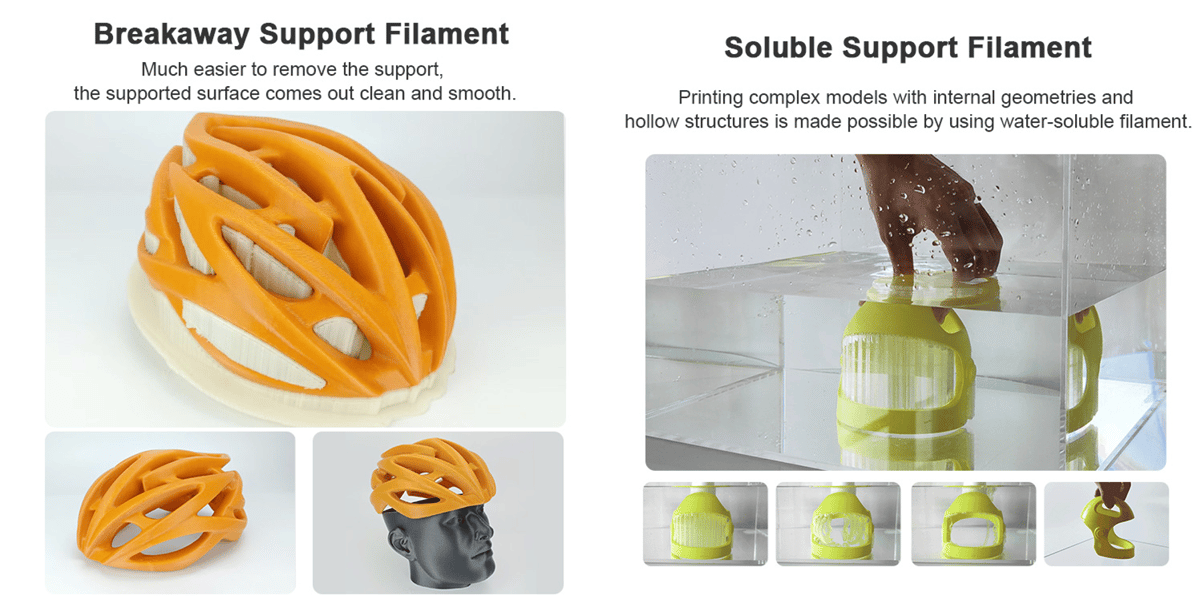

The most noteworthy mode offered by the MD-400D is Support Mode, which assists in printing complex structural models with remarkable precision. This support-focused feature enables user to print with high-performance materials and breakaway material. Complex models with overhanging elements often require support structures, and this is especially true when working with advanced materials. By utilizing the second extruder for support printing with a breakaway filament, the MD-400D simplifies support removal, ensuring a smooth and successful printing experience.

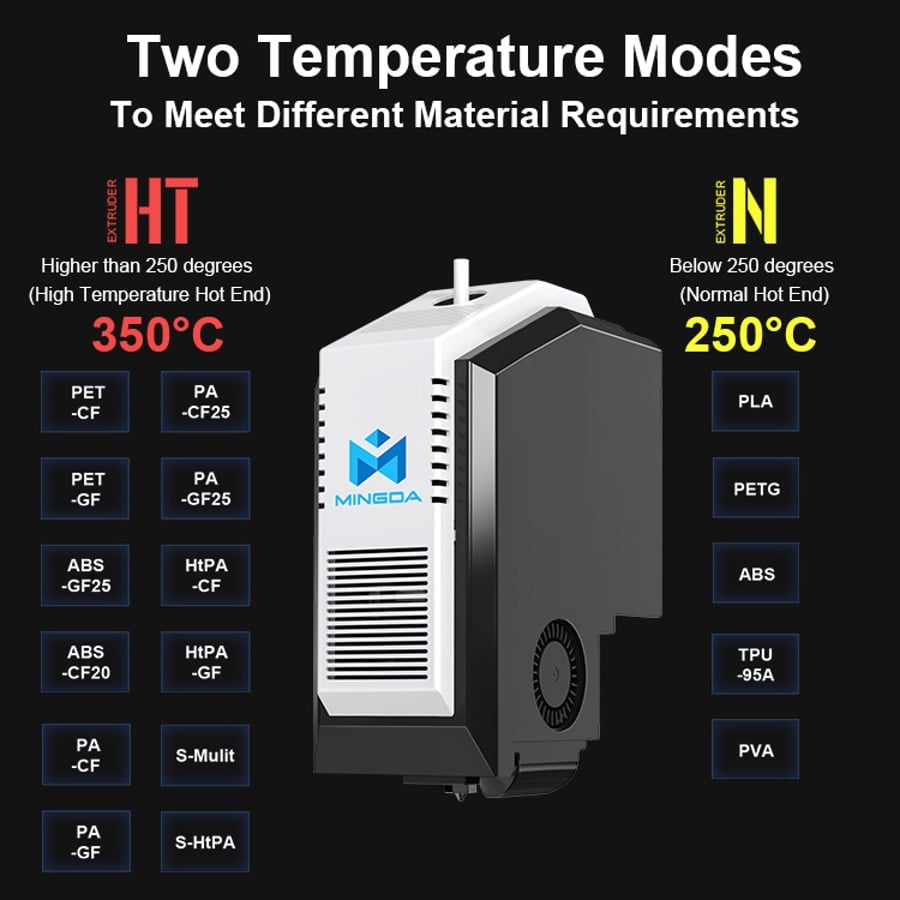

The printer’s dual gear direct extruder gives it a unique ability to handle flexible filaments. Moreover, the MD-400D is built to accommodate both high-temperature and common hot ends. The max temperature of the basic hot end can reach 250°C, supporting popular materials like PLA, ABS, PETG, TPU, and others. The high-temperature hot end can reach 350°C, making it compatible with advanced materials such as PET-carbon fiber, PET-glass fiber, Nylon carbon fiber, Nylon glass fiber and other composite filaments, broadening the scope of printable materials and potentially catering to a wider audience with varied needs.

But the premium extrusion system is not the only feature worth mentioning, the MD-400D offers advanced features and a sturdy build that make it an ideal match for professionals and hobbyists alike.

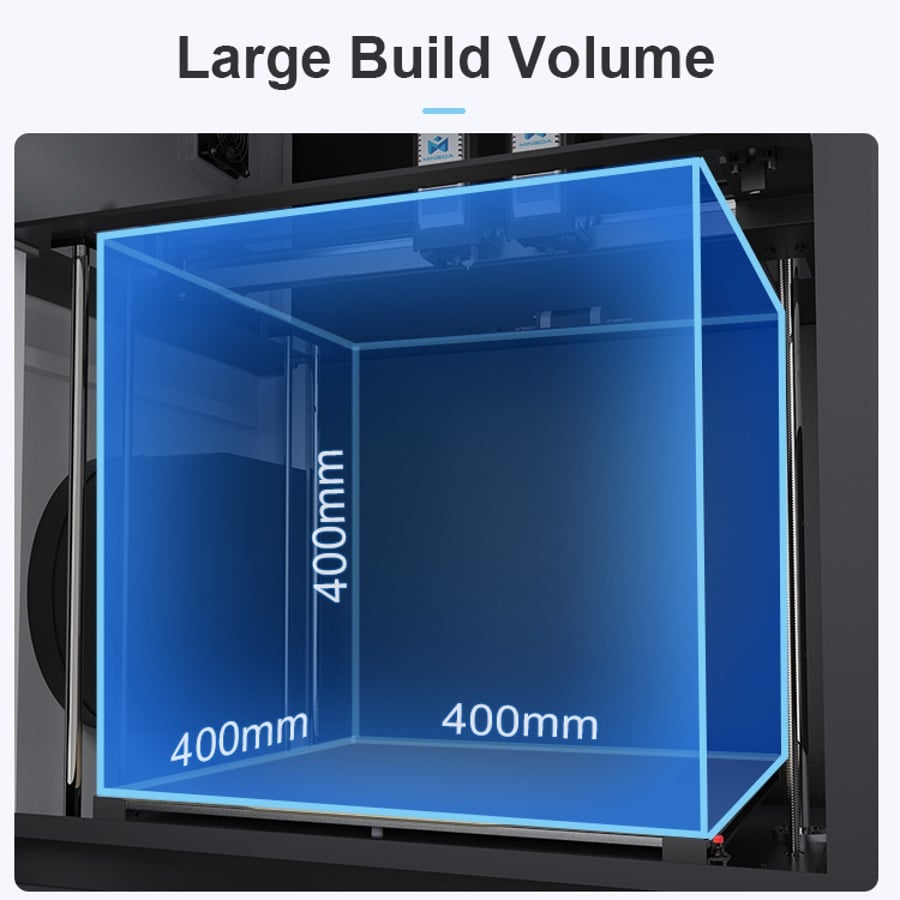

Expansive Building Size

The building size of the MD-400D surpasses its counterparts, with the free mode reaching 400 x 400 x 400mm. Despite the reduced print areas in Duplicate and Mirror Modes, they still offer a substantial workspace that most IDEX 3D printers lack.

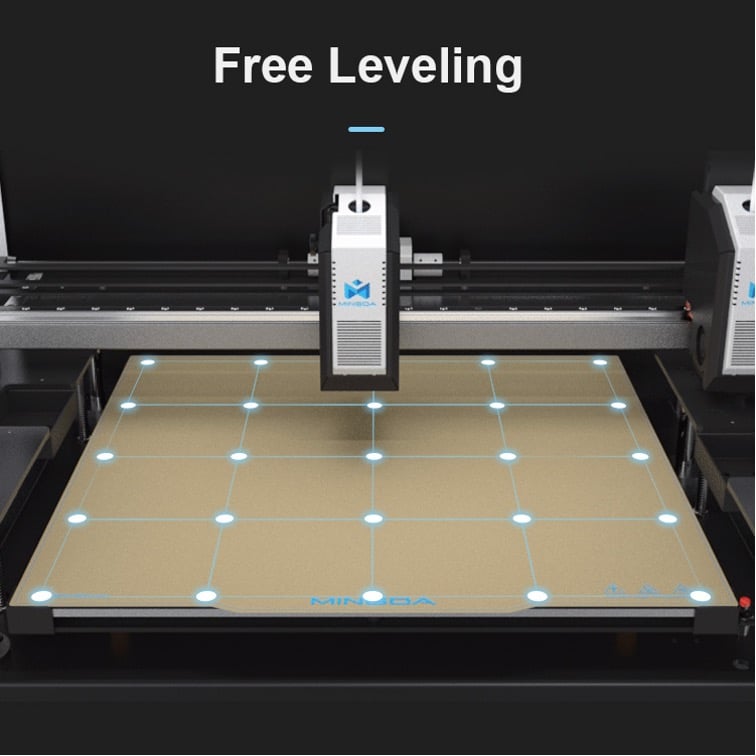

Intuitive Leveling System

The MD-400D incorporates an automatic leveling system, which aims to mitigate print failures attributed to unleveled build plates. This feature appears to provide users with enhanced print quality and stability.

Practical Platform Design

This 3D printer features a flexible PEI platform. Known for its impressive viscosity, it aims to prevent model warping during the printing process and allows for effortless removal of completed prints.

Durable Machine Body

The MD-400D, crafted with a fully metal enclosed chamber, is designed to maintain a consistent printing temperature, which could be particularly beneficial when working with materials such as ABS. The enclosed structure may play a vital role in minimizing print errors like model shrinkage and filament breakage.

User-friendly Touch Screen

Equipped with a 5-inch touch screen, the MD-400D’s interface is designed to be clear and user-friendly. This feature aims to minimize operational complexities and enhance user experience.

Multiple Print Interfaces

This printer supports SD, U-disk, and Type-C printing methods, thus offering a range of import options for 3D models.

Air Filtration System

During the printing process, the air filtration system can effectively clean particles (including nanoparticles) in the air. The system operates silently to ensure a quiet working environment.

MINGDA MD-400D: A Highly Capable, Versatile Machine

With a strong focus on multi-material capabilities, the MINGDA MD-400D is positioned as a high-temperature IDEX 3D printer suitable for a range of applications from complex prototyping to education. However, the extent to which it delivers on these promises will likely be determined by user experience in diverse settings.

The MINGDA MD-400D 3D printer indeed presents an array of impressive features. With its multi-material capabilities and versatile design, it’s potentially poised to redefine expectations within the 3D printing sphere.

MINGDA MD-400D: Tech Specs