As every 3D printing enthusiast knows, combing through the countless filament brands and material types can be quite a daunting task. Every consumer or professional is searching for something to suit their unique needs. Professionals may need specialized properties or high strength, hobbyists may need a specific color or aesthetic, environmentally-minded makers may want a sustainable and eco-friendly alternative to everyday plastic.

Fiberlogy, a Polish material producer, is banking its success on the fact that it has a material for every kind of user and 3D printing project. The manufacturer is steadfast in its mission to bring uniqueness and high-performance to the FDM 3D printing filament market.

Its team of experts have years of experience in plastic processing and profile extrusion, ensuring that its growing portfolio of filaments offer top-notch properties and parameters. In fact, Fiberlogy guarantees that its vast range of 3D printing materials have a diameter tolerance of +/- 0.02mm and oval tolerance of +0.01mm.

Aiming at both professionals and hobbyists, Fiberlogy has taken an expansive approach to its product development strategy. While quality and precision is valued across its entire portfolio, the filament manufacturer now offers over 15 different types of 3D printing filaments. This selection now includes an array of high-strength Nylon materials and an eco-friendly, 100% recycled filament line.

Fiberlogy’s Nylon Filaments Deliver Durability and Strength

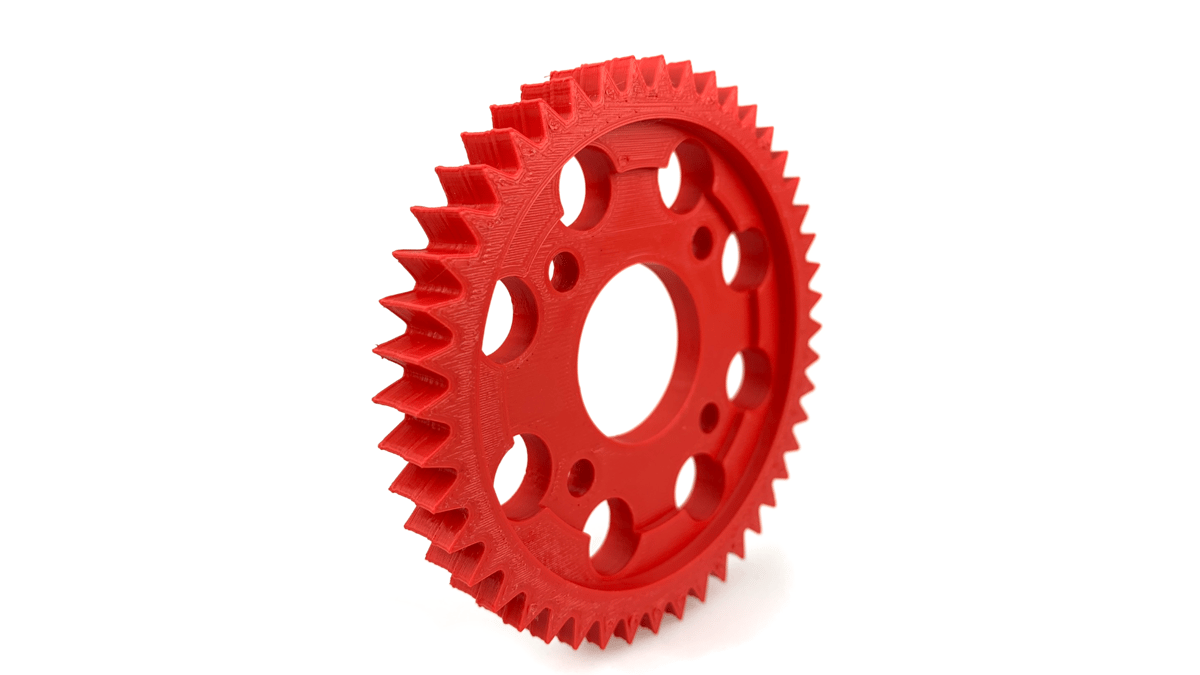

For professionals who need a material that is highly durable, resistant to elements like heat and chemicals, and all-around stiffness, Nylon filament is a top option for FDM 3D printing. Fiberlogy has released a wide series of nylon-based filaments that satisfy almost any functional application.

Aside from a standard Nylon PA 12 filament, the producer has also conjured up materials that are reinforced with glass fiber and carbon fiber. Here’s an overview of Fiberlogy’s Nylon offerings:

- Nylon PA12 – Those who need an incredibly durable material for end-use parts or functional prototyping should look no further than this Nylon PA12 filament. Ideal for mechanical and technical applications, Fiberlogy Nylon PA12 is prized for its durability, strength, and ability to expand to 50% before breaking. Machinable and paintabile, this Nylon PA12 is resistant to high temperatures and chemicals.

- Nylon PA 12+GF – A glass fiber reinforced derivative of Nylon PA12, this version takes durability, stiffness, and thermal and chemical resistance up a level. Containing 15% glass fiber, PA12+GF15 has a stiffness of 3.6 GPa and a temperature resistance of up to 170°C. Compared to Carbon Fiber-reinforced Nylon, this iteration offers greater flexibility, making it ideal for high stress or impact applications. It should be noted that this material is quite abrasive, so users should only print this filament through steel or ruby nozzles.

- Nylon PA 12+CF – Fiberlogy offers two variations of carbon fiber-infused Nylon PA12, one with 5% and another with 15% reinforcement. The combination of carbon fiber with nylon enables users to print objects with high thermal resistance and less shrinkage than standalone Nylon PA12. Another benefit of carbon-fiber reinforced filaments is the reduction of weight, while still maintaining strength and stiffness. It is worth noting that Nylon PA12+CF15 does not require a heated chamber, which makes it extremely easy to use, e.g. on Prusa i3 printers. Created for the likes of the automotive and engineering sectors, Nylon PA12+2 + CF5 and Nylon PA12+CF15 can be used to 3D print functional prototypes and even lightweight end-use parts that require increased durability.

Fiberlogy R Series: 100% Recycled Filament

Clearly, the expansive range of Nylon filaments are geared toward professional applications. On a global scale, Fiberlogy is also focused on making the 3D printing industry more sustainable and environmentally-friendly.

One criticism commonly leveled upon 3D printing technology is the waste it can sometimes leave behind. After reflecting on this glaring industry-wide issue, Fiberlogy decided to develop a 100% recycled filament line called Fiberlogy R.

Combining its highly optimized filament production process with thoughtfully obtained recycled plastics, the material product was able to create a high quality filament that minimizes the impact on our ecosystem.

Fiberlogy selected and derived raw material from verified sources, eliminating any chance that the filament wasn’t contaminated or unsustainably sourced. After production, this fully recycled filament is also properly stored before being shipped, ensuring that customers receive an optimal and unspoiled product.

The Fiberlogy R series includes 100% recycled variations of some of the most widely used filaments, including PLA, ABS, Nylon, and PP. Here’s a brief overview on each

- R ABS – This material offers high hardness, high impact resistance, and can withstand high temperatures and abrasion.

- R Nylon – Fully recycled Nylon filament is highly flexible, resistant to abrasion, and resistant to high temperatures and chemical compounds.

- R PLA – Known for being biodegradable, this fully recycled PLA allows users to print objects without concern for where the material was sourced from. Depending on the specific batch, R PLA filament may contain traces of glitter and vary in the intensity of coloring.

- R PP – This Polypropylene is non-toxic and odorless, highly resistant to chemicals, and can also withstand physical force or damage. According to Fiberlogy, it has very good adhesion between the printing layers.

Each filament type comes in anthracite and a 1.75mm diameter. Users can leverage this eco-friendly filament for several applications, including toys, figurines, miniatures, prototypes, gadgets, jewelry, decorations, and even end-use parts.

You can learn more about the unique properties of the Fiberlogy R product line here, along with where you can buy the filament. Be sure to check out the Fiberlogy website to explore the various other types of filament they have on the 3D printing market.