The 3D printing industry encompasses a wide range of specialties, from desktop projects to large-scale additive manufacturing, materials development, and diverse types of 3D printers. One particularly innovative, but often overlooked, niche within this industry is filament extrusion.

Why Would Anyone Make Their Own Filament?

Globally, 3D printing generates a significant amount of plastic waste, estimated at around 8 million kilograms annually from failed prints and excess material. We all try to be conscious of the waste we produce, and a build-up of plastic scraps is a familiar reality for anyone working with 3D printers.

One solution that has become more popular within the community is making filament from expensed filament. Converting this waste into reusable material is just one advantage to in-house filament extrusion. Other benefits include giving a cost-effective alternative to purchasing expensive filament, and flexibility for experimenting with unconventional materials.

Whether you’re a researcher, engineer, or working in education, filament-making can significantly enhance your 3D printing capabilities and sustainability efforts.

What Does 3devo Have To Do With it?

3devo is a Dutch technology company with extensive knowledge and first-hand experience in filament extrusion. The company’s Filament Maker machine enables desktop-style accessibility for materials research and exploration. From processing standard waste PLA and PET, to experimenting with complex materials such as SLS/MJF and PCL, to creating composite materials in-house (think carbon fiber and metal powders, for example) – a Filament Maker brings freedom to experiment and push boundaries.

How Does a Filament Maker Work?

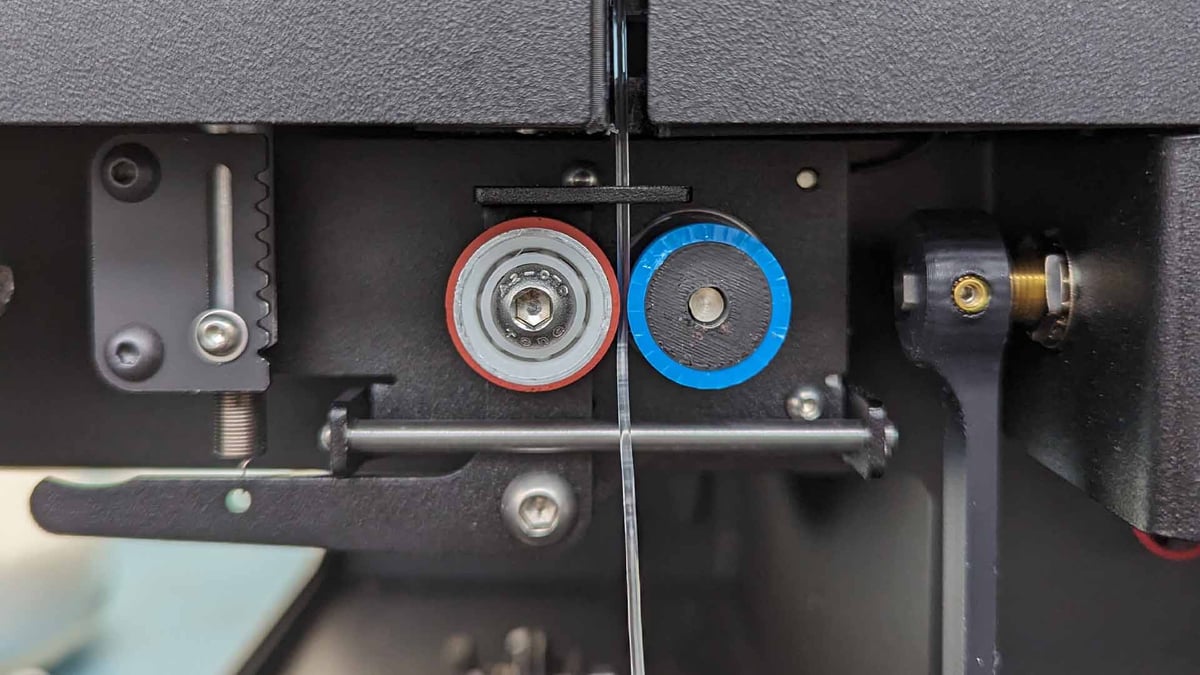

The desktop filament extrusion process begins with raw plastic pellets or recycled plastic materials, which are fed into a filament extruder. This device heats the plastic until it melts, ensuring a consistent quality through precise temperature control. Once melted, the plastic is pushed through a nozzle to form a thin, continuous strand of extrudate. This is then cooled and wound onto a spool, ready for use in 3D printing.

One key benefit of in-house production is the autonomy it gives to users. The 3D printing industry is inherently experimental, with a relatively low entry point that encourages exploration and pushing past limitations. It is only natural that users of 3D printers apply this same mindset to their materials, asking questions such as: Can I print with complex composites or additives? How can I reuse this waste material? What do I do with the leftover print supports?

With a machine such as 3devo’s Filament Maker, it is possible to successfully explore the answers to these questions. A research tool designed to give users the best possible chance of successful extrusion, the Filament Maker encourages users to discover their own project-specific configurations and settings.

How Does Filament Extrusion Actually Work?

Filament extrusion isn’t just about creating 3D printing material; it also opens up new avenues for innovation and efficiency in various industries. Some great examples of this can be seen in the medical field, where precise and reliable material properties are paramount. The benefits even extend to other areas of 3D printing, as waste material from a range of print methods can be recycled.

Extrusion for medical applications

Biomedical start-up Lattice Medical used a 3devo Filament Maker ONE to develop their innovative bioabsorbable breast implant, Mattise. The machine allowed Lattice to experiment efficiently with a very expensive material, priced at €5000 per kilogram, minimizing waste and optimizing production. The ability to create filament on-site proved to be crucial for testing and producing high-quality filament needed for 3D printing their medical implants. This capability not only made Lattice’s production process more cost-effective and sustainable, but also accelerated their research and development efforts.

Beyond FDM waste

Another success story for filament extrusion is the ability to recycle waste SLS/MJF powder into FDM filament. Traditional SLS and MJF processes often result in a substantial amount of leftover powder – up to 60% – that cannot be reused in subsequent prints. This not only leads to a lot of material wastage but also poses disposal challenges, thanks to the fine and potentially hazardous nature of the nylon powder.

In just a few hours, a Filament Maker can transform waste SLS and MJF powder into a spool of reusable filament, offering a solution to a costly and frustrating issue.

Is Filament Extrusion “Easy”?

It is important to keep in mind that filament extrusion is not a plug-and-play process. Those who have been working in the 3D printing industry for many years will recall the first generations of desktop printers and the period of familiarization necessary for optimal use. The same should be expected from the filament extrusion process.

Creating high-quality filament involves several stages of trial and error. This process begins with selecting the appropriate raw materials and understanding their properties, which can significantly impact the performance of the final filament. Testing different temperatures, extrusion speeds, and cooling rates is essential to achieving consistent results. Each material behaves differently, and fine-tuning the process is crucial to ensure the filament meets the industry standards.

Are There Ways to Increase the Likelihood of Success?

For those new to filament extrusion, or those working with complex materials, the process can be daunting. Access to guidance and hands-on assistance, such as that provided by 3devo, helps navigate the complexities of material selection and process optimization.

Here are some ways that a user is supported when working with a machine such as 3devo’s Filament Maker Series:

Material Testing

Expert advice from an in-house team of Materials Specialists can help evaluate the performance of chosen materials, so users feel confident in their decision-making. It is also a good idea to look at a company’s offering of pre-emptive validation services, such as Melt Flow Index (MFI) Testing and Filament Development Analysis – these tests can indicate the likelihood of successful extrusion, giving a level of security for such an investment.

Process Optimization

Fine-tuning the extrusion process is critical to producing high-quality filament. Having direct access to an experienced team helps optimize temperature settings, extrusion speeds, and cooling mechanisms. At 3devo, a Materials Specialist passes on their knowledge and experience, initially during a 2-month professional onboarding as well as throughout the project as needed, to ensure the user’s project stands the best chance of success.

Training and Workshops

Whether that be welcoming users to the 3devo Innovation Lab, or sending out a Materials Specialist for machine onboarding, a hands-on approach to covering extrusion techniques, troubleshooting, and optimization can be really beneficial. Think of it like having a project partner as invested in your project’s success as you are.

With an experts’ guidance and services such as those provided by 3devo, you can feel confident in making informed decisions and concentrate on what truly matters – your project.

What’s the Impact of Desktop Filament Extrusion?

In-house filament extrusion is a game-changer for 3D printing. By producing filament on-site, users can minimize waste, experiment with diverse materials, and streamline their production processes. Tapping into the expertise and support available from solutions providers such as 3devo means users can navigate the complexities of filament extrusion with confidence and autonomy. Embrace the potential of in-house filament extrusion to enhance your 3D printing projects, drive innovation, and contribute to a more sustainable future!

Are you ready to learn more about the filament making process? Get to know the machines, process, and how desktop filament extrusion can work for you, here.