Like a lot of people stuck at home during the pandemic, Khalid Bou-Rabee missed his gym workout. His small New York City apartment didn’t offer a lot of space for equipment, so his ability to get an effective weightlifting workout faded along with his toned physique. If only there was fitness equipment that didn’t take up space but offered the same capabilities as a barbell and squat rack with hundreds of pounds of weights?

There wasn’t, until Bou-Rabee invented it.

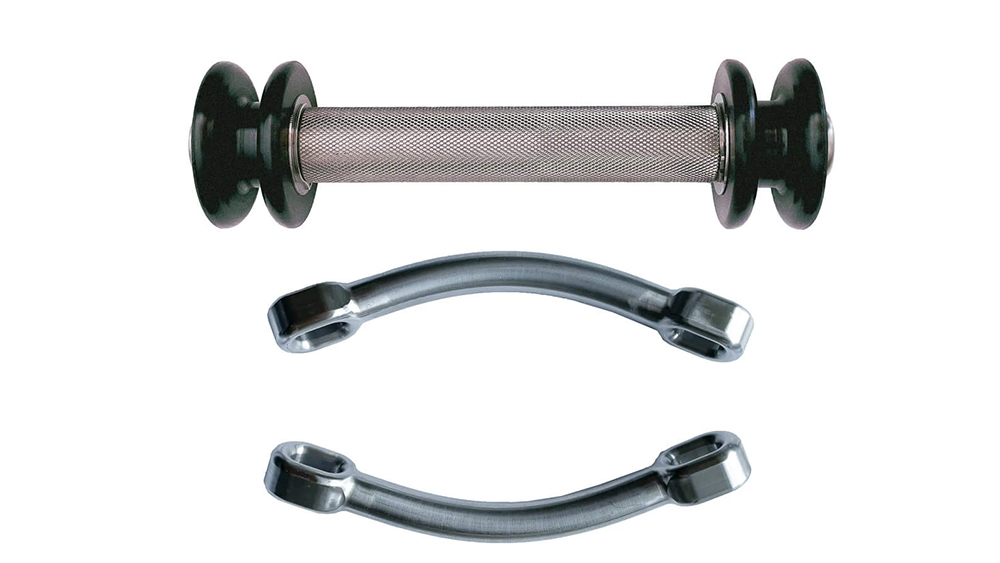

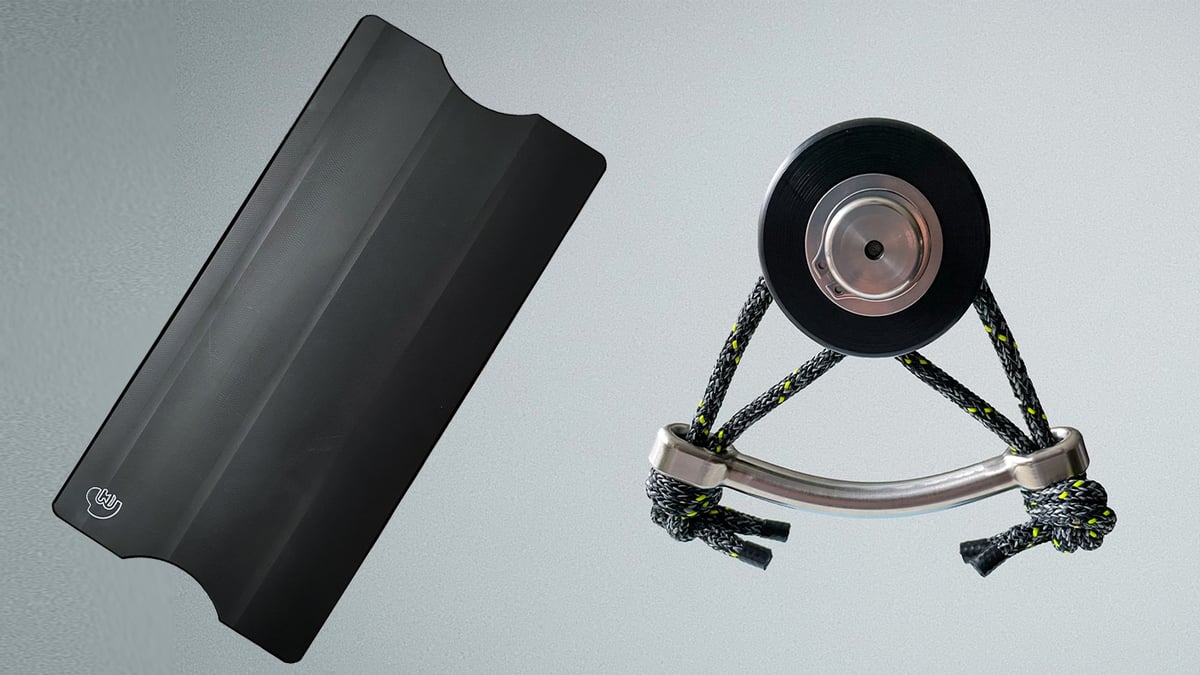

The Harambe System is a new type of band resistance training solution so elegant and effective that it’s quickly making converts among fitness trainers and serious home workout devotees. Consisting of a bar, bands, a footplate, and accessories, the system promises a workout with resistances up to 1,000 pounds of force in the privacy of your own living room.

But before the Harambe System was a promising fitness device, it was a prototype, and that’s where 3D printing through Craftcloud, the 3D printing marketplace, came in.

Quality Prototypes Within Reach

3D printing services are enabling more entrepreneurs to bring their ideas to life faster and cheaper than ever before. Because single prototypes of just about any product can be printed in engineering-grade materials at a fraction of the price of CNC machining or injection molding, and delivered in just days instead of weeks, inventors can afford to refine their ideas through multiple iterations and get their products to market faster.

Craftcloud, the 3D printing marketplace, connects entrepreneurs like Bou-Rabee with 3D printing companies who provide an instant quote based on an uploaded digital part file.

“Craftcloud was instrumental in the whole development process for the Harambe,” says Bou-Rabee. “I had no idea that it would be so affordable to get functional, high-quality prototypes so quickly.”

3D Printing & Product Development Cycle

The innovative Harambe System uses slings and pulleys to attach bands to the bar. The patent-pending pulley system is exceptionally smooth, never jerky, and the force you feel while using it is only in the direction of the band, which is something quite revolutionary in band fitness equipment.

As Bou-Rabee explains it: “The geometry of the sling is mechanically so strong that the metal part can be wide without sacrificing strength, allowing the bands to easily slide after loading for easy setup. By using 3D printed spacers or longer rope, you can predictably adjust the force using small steps, finally bringing true progressive overload training (which is a staple among free weights) to bands. Resistance bands increase their resistance as they stretch, so to accommodate a lift with at least 500 pounds of force (227 kilos of force) throughout the entire range of motion, Harambe System’s working load is a striking 1,000 pounds of force (454 kilos of force).”

But to get to this stage, Bou-Rabee went though a lot of prototypes.

Prototype Proof of Concept

Bou-Rabee has a PhD in mathematics from the University of Chicago so he had the skills to develop the computer simulations required to design strong and safe parts. “Computer simulations can be very accurate, but nothing can replace real-world testing. I needed prototypes,” he says.

At first, the young entrepreneur thought he’d order a stainless steel prototype for the main bar and pulleys of the system, but changed his mind quickly when he was quoted at over $1,000 for a single CNC machined metal part. “I needed something strong to test,” says Bou-Rabee, “but it didn’t need it to be metal.”

The idea to 3D print came from a friend who, as a hobby, 3D prints parts to modify fitness equipment.

“I didn’t have space in my apartment for a weight rack, so I certainly didn’t have space for an industrial-grade 3D printer,” says Bou-Rabee, who then researched how to order 3D printed parts online.

“First, I reached out to Xometry because it was the first 3D printing company that popped up after a Google search,” he says. “The Xometry parts turned out to be too expensive and the Xometry interface was difficult to navigate.”

In fact, the slings printed out of polycarbonate at Xometry were more than $250; not a realistic price for something that he would need to refine and reprint several times. For his next prototype iteration, he investigated other services. “I looked at ProtoLabs, Shapeways, Sculpeto, and Hubs, but decided to go with Craftcloud.”

“Craftcloud is so easy to use,” says Bou-Rabee, “you just drag and drop your design file and up pops a selection of materials and quotes from different manufacturers. Craftcloud has connected me with some really great manufacturers and the customer service made it even easier.”

Prototypes from Craftcloud were about 30% less than Xometry for the same models. Bou-Rabee ended up ordering about 40 more prototypes from Craftcloud – many in engineering-grade Nylon printed via multi jet fusion –until his design was finalized.

“I could get parts within days from Craftcloud, which was very helpful,” he says. “I 3D printed prototypes using PETG, PLA, MJF Nylon PA12, ABS, and polycarbonate. Craftcloud really explains material properties well; this helped a lot.”

Once the design was nailed down, it was time to order parts in their final material, which meant an investment in stainless steel and CNC machined UHMW (ultra high molecular weight polyethylene). Being able to evaluate multiple iterations enabled Bou-Rabee to move to final production with the same digital files used for the prototypes, and with confidence that his steel and CNC machined parts would be completely accurate.

The high-quality of the Nylon 3D printed parts from Craftcloud convinced Bou-Rabee to use 3D printing for some final parts of the Harambe System.

“The spacers, which are an essential and unique part of the entire system, are 3D printed in Nylon using multi jet fusion. Spacers take heavy loads, at least 300 lbs each. I initially ordered prints thinking they would be prototypes, but the mechanical strength, finish quality, and economical pricing of the parts from Craftcloud, convinced me to use them as final parts.” Moreover, the rough surface finish of MJF parts is actually an advantage, as it secures the spacers to the rope slings.

Bou-Rabee spent months of the pandemic lockdown working on the Harambe System. “I honestly had no idea how long it would take,” he says, “but I was able to go from pencil sketches on scrap paper to a final product in less than a year thanks to Craftcloud.”

Since officially launching the product in February of 2021, Bou-Rabee has sold hundreds of systems across the country. “Fitness trainers have purchased the Harambe System for use with clients in their homes and then the clients end up buying their own systems.”

Fitness clubs have also expressed interest in the patent-pending design of the system, and Bou-Rabee is hopeful to sell to them in volume one day. Bou-Rabee knows Craftcloud’s production abilities will never be a bottleneck. “I’ve ordered thousands of spacers from Craftcloud and gotten them really quickly,” he says.

Craftcloud’s growing network of 3D printing manufacturers means volumes can be sourced from multiple companies to meet nearly any size demand.

As the Harambe System gains followers, production will eventually scale up, but 3D printing will remain a part of the mix, Bou-Rabee says. “Craftcloud was an essential partner in the development of the Harambe Systems, and I’m sure the relationship will continue as we grow.”

And grow it will. The Harambe System has thousands of followers on Facebook and Instagram, and Bou-Rabee himself has been called the Doctor Strange of the fitness industry. A suitable title for anyone who uses science and advanced technology to invent something truly groundbreaking.

Share Your Craftcloud Story

Harambe System was selected to be featured here as part of the Craftcloud Stories campaign to highlight innovations made possible through 3D printing at Craftcloud, the 3D printing marketplace provided by All3DP. If you’d like to share your company’s story, stay tuned to Craftcloud for the next campaign by signing up for the Craftcloud newsletter.

Lead image source: Harambe System

License: The text of "Fitness Innovation via 3D Printed Prototypes" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.