Desktop Metal this week unveiled a new family of photopolymer foaming resins that expand when heated in a first for the 3D printing industry. Previously, foaming materials were only available in filament form, which can’t achieve the level of fine detail that resin printers can.

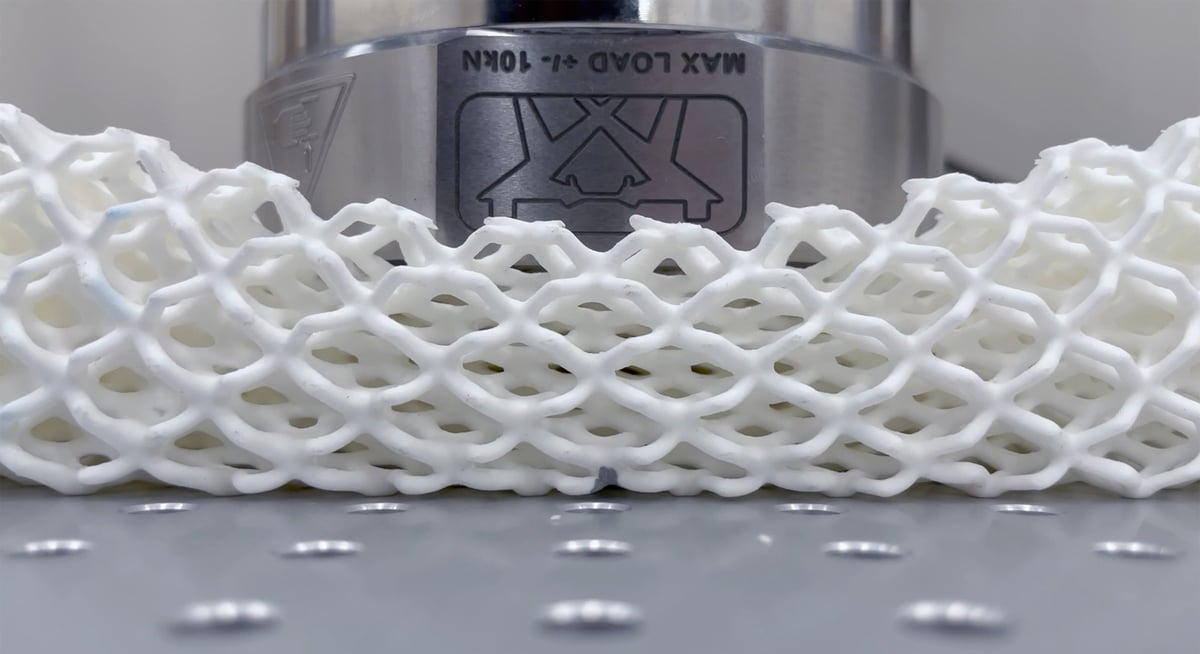

Although 3D printers today can process standard polymers into lattice designs that simulate foams, FreeFoam is a true foam material, Desktop Metal says.

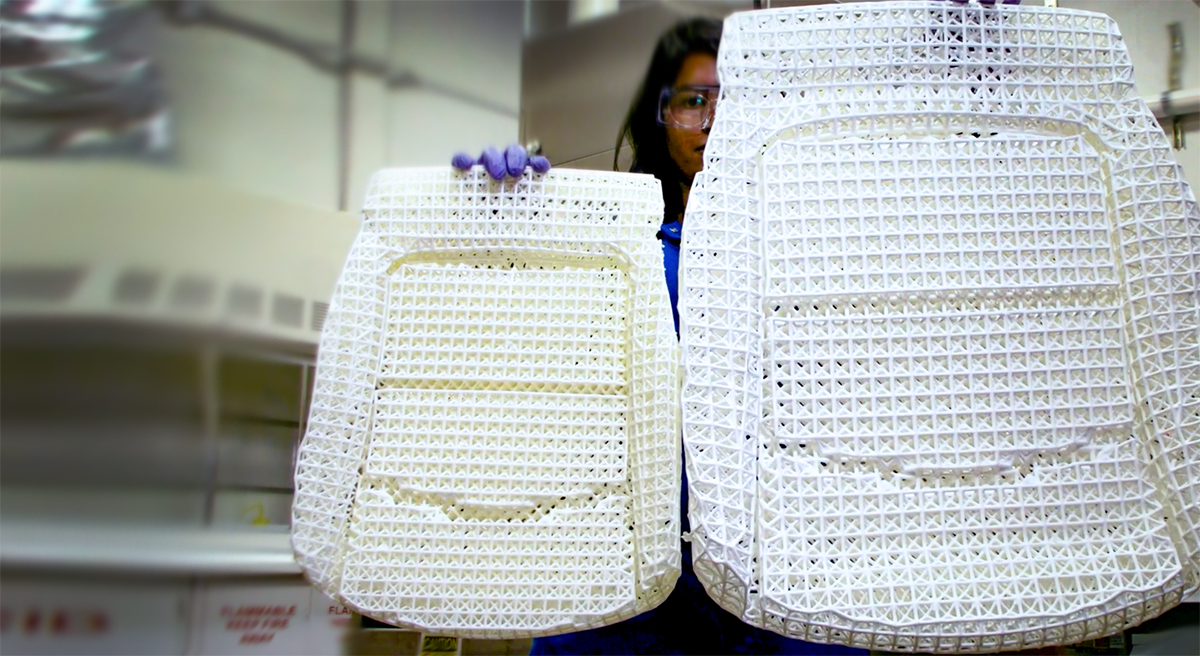

Designed for 3D printing lattice structure-type padding or fully dense foam, FreeFoam can be used to 3D print everything from automobile seat cushions to padding for sporting goods to healthcare products. Without the need for molds as tooling and eliminating the waste associated with traditionally manufactured foam products that are cut and shaped, 3D printing produces more complex shapes and variable stiffness padding with virtually no waste.

Desktop Metal says the highly controllable process causes FreeFoam resins to consistently expand 2 to 7 times their as-printed sizes depending on the grade of resin, achieving final parts within desired tolerances. This feature enables FreeFoam parts to be shipped in a compact form and expanded on-demand in an oven close to the final point of use or assembly, saving shipping and inventory expenses. This new process allows 3D printers to produce much larger final foam parts than the printers’ original build areas.

Every year, more than 1.5 billion pounds of foam is produced for products that touch nearly every industry. There’s a lot of labor involved to cut and shape bulk foam and tools and mold needed to create specific shapes. FreeFoam opens up new opportunities for foam in customized and low volume parts as well as mass-produced parts that are easier and less expensive to ship, although there has to be an oven to expand the printed products at the point of assembly. Desktop Metal says FreeFoam is lighter and less bulky than traditional foam.

The resin produces durable and dimensionally accurate closed-cell foam parts that, after printing, expand in an oven at 160°C – 170°C.

FreeFoam resin will be offered in a wide range of Shore hardness values and will initially be 3D printable exclusively on the ETEC Xtreme 8K top-down DLP system from Desktop Metal’s polymer 3D printing brand.

FreeFoam was invented and developed by Texas-based Adaptive3D, a subsidiary of Desktop Metal that was acquired in 2021. The resins are 3D printed similar to other photopolymer resins using DLP. The printed parts contain dispersed heat-activated foaming agents that create closed cell pores inside the material.

While preliminary specifications for FreeFoam are now available, Desktop Metal plans to offer several grades of FreeFoam resins with different Shore hardness values and other specific materials properties, such as water resistance for the outdoor furnishing market.

No release date or pricing was announced, but Desktop Metal says it’s working now with major manufacturers of foam products, including Camaco, which produces automobile seating.

License: The text of "Foaming Resin for 3D Printed Parts That Poof When Heated" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.