A French family recently became the first in the world to move into a fully 3D printed house. The spectacularly sized family home was built as a part of a project that aims to use additive manufacturing to construct buildings in a quick and affordable manner.

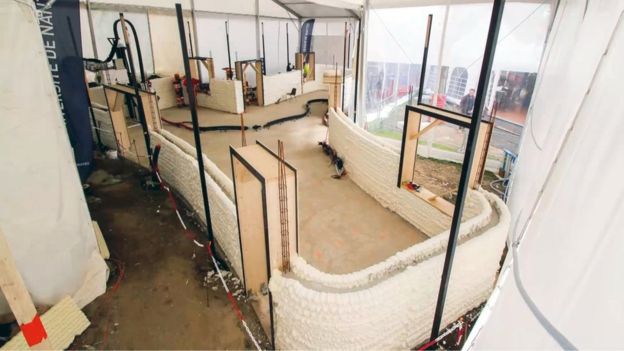

This 3D printed home was constructed in a collaborative effort involving the University of Nantes, the city council and a construction company. The longterm aim of the project is to figure out whether 3D printing is really a viable option for building inhabitable structures. Benoit Furet, who spearheaded the project at University of Nantes, developed the initial concept of the house.

The sizable house in Nantes measures out to 1022 square feet, equipped with four bedrooms and a large central living area. Despite the generous size of the home, it took just 54 hours to print the main structure. The team believes that they can cut this construction time down to 33 hours in the near future. This home is just a prototype and the team intend on 3D printing bigger structures in future.

Perhaps the most impressive aspect of this project is that the house cost just £179,000 (around $238,792) to build. This is about 20 percent cheaper than homes that are built using traditional construction methods.

The 3D printed house was built to be “allocated to a family according to the usual criteria of social housing”. That lucky family ended up being Nordine and Nouria Ramdani, along with their three children.

“It’s a big honour to be a part of this project. We lived in a block of council flats from the 60s, so it’s a big change for us. It’s really something amazing to be able to live in a place where there is a garden, and to have a detached house,” Nordine Ramdani said.

What Does This 3D Printed Home Mean for the Future of Social Housing in France?

By using 3D printing, many architects are finding that the technology allows them to get more creative with their ideas and concepts. The house in Nantes, for example, is designed to curve around 100-year-old protected trees on the plot. Additionally, due to the reduction of material waste, the technology offers a more environmentally friendly way of building homes compared to traditional construction methods.

Other modern technologies are implemented in the 3D printed home, including digital controls, curved walls to reduce humidity and equipment to analyze aspects such as air quality, helping the tenants save on their energy bills. Better yet, all of these digitalized settings can be controlled via a smartphone.

“For 2,000 years there hasn’t been a change in the paradigm of the construction process. We wanted to sweep this whole construction process away. That’s why I’m saying that we’re at the start of a story. We’ve just written, ‘Once upon a time’,” said Francky Trichet, the council’s lead on technology and innovation.

The team believes that in five years, the cost of constructing houses will be reduced by 25 percent and as much as 40 percent in 10 to 15 years, all while still following current building regulations. This prediction takes a number of factors into account, such as 3D printing technology becoming cheaper and economies of scale as more homes are built.

Excitingly, if this future forecast goes according to schedule, we could be seeing a lot more 3D printed homes in France and throughout the world, providing the ability to construct creative architectural designs while reducing the long waiting list for those who need social housing.

Source: BBC

License: The text of "French Family Becomes the First to Move into a 3D Printed Home" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.