After years of perfecting its new Catalyst engine for turboprop planes, which uses 3D printing to deliver reduced fuel burn and weight, GE Aerospace now has US Federal Aviation Administration (FAA) certification. The company plans to ramp up production of the engine, which will first be available in Textron Aviation’s upcoming Beechcraft Denali turboprop next year.

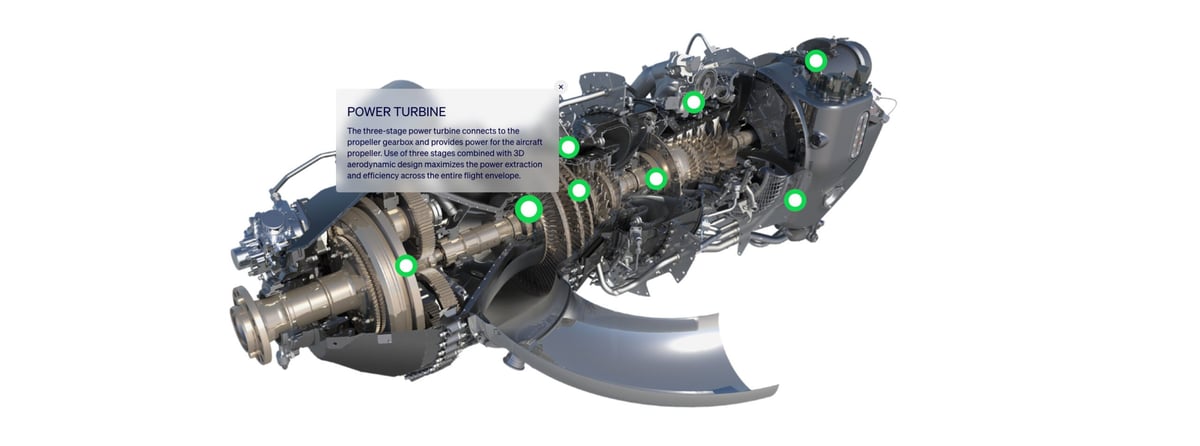

“Catalyst is the first turboprop engine in the aviation history with extensive use of additive manufacturing technology,” says Avio Aero, a GE Aerospace company and contributor to the engine’s R&D. 3D printing in combination with advanced alloys enables parts with more geometrical freedom in the design, the company said.

GE noted in previous updates on the Catalyst development that it was able to reduce more than 800 conventionally manufactured parts to 12 additive parts on the engine. Parts are produced using metal laser powder bed fusion and electron beam melting.

Catalyst enables up to 18% better fuel consumption and up to 10% higher cruise power than competitors in the same engine class. The engine also has the best power-to-weight ratio in its engine class, which contributes to increased range, added payload, and a larger, quieter cabin.

Following extensive evaluation involving over 23 engines and more than 190 component tests, Catalyst is the first advanced turboprop to be certified to the latest standards, which include more than 20 significant new requirements, according to GE Aerospace.

“The certification of the Catalyst engine is a significant milestone for our company and a proud moment for all our team members who have dedicated their efforts to the design, development, and testing of this brand-new European turboprop engine,” says Riccardo Procacci, president and CEO, propulsion and additive technologies at GE Aerospace. “We are now fully committed to supporting the production ramp-up of the engine towards the entry into service in support of our customers.”

You May Also Like:

License: The text of "GE Catalyst Turboprop Engine with 3D Printed Parts Gets FAA Certification" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.