New product spec dumps are a little dull, so we’ve imagined an interview with the Prusa Pro HT90, instead.

So, you’re a new Prusa 3D printer, aren’t you?

Yes.

Don’t people usually get a bit more excited about these things?

Well, it’s not like I’ve been a secret. I was on display at Formnext in 2023, and the team that made me, Trilab, was acquired in 2021. It’s been a long time coming, really.

But the interested 3D printing masses crave new hardware. Where’s the noise? The hype?

I’m not really for them. My name gives you a clue, Prusa Pro, but I’ll admit it’s a bit more nuanced than that.

Oh, so you’re a 3D printer for professionals? What does that really mean?

Okay so the regular Original Prusa hardware, the i3/MK series and Minis, are great. Loved by all, used by all, and I mean all. There is a long list of important companies that use Prusa hardware to make things go really really fast. Those are 3D printers used by professionals already – so to say I’m just a 3D printer for professionals misses the point. It is, ultimately, just a name. What the name does do, however, is show who Prusa Research expects to be interested in me.

As great as the Original Prusa machines are, their capabilities are limited—that’s where I step in.

Limited? Meaning what – not fast or accurate enough?

Not quite. For end-use parts that are used in undemanding situations, they’re great, but if you need a part to maintain its dimensions and perform against temperature extremes, chemicals, oils, or processes that come with the territory of industrial use, then you need to look at plastics that are, typically, much tougher to print.

Oh, so you print carbon-fiber stuff better?

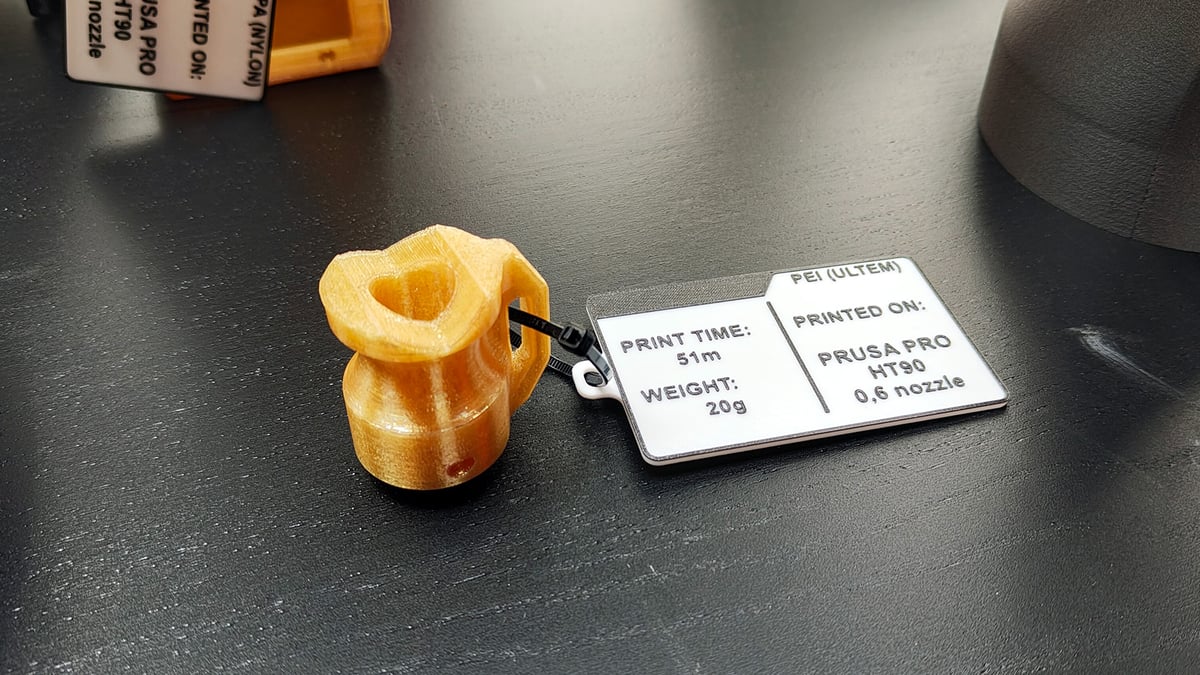

Again, not quite. I certainly can, but I’m more interested in tackling larger-scale prints from ASA, PC, and the like, plus the tougher, more chemical and temperature-resistant materials like PEI and PEEK.

PEI?

Yes – polyetherimide. Where regular Original Prusa machines top out at materials like ABS and PC (and even then, there are limits to the complexity of what you can print), I can do those comfortably, and then some. Think of it as the range of materials I can process expanding upwards, to include more demanding plastics that would be impossible to print on a regular Original Prusa 3D printer.

Aren’t materials such as PEI ultra-hygroscopic?

They are indeed. For those materials, I come with a handy hermetically-sealed DryBox case that can keep the active spool dry for the duration of printing. Beyond this, a filament drying oven from my partner Memmert is available. For everything else, there’s a front-mounted spool holder for easy access.

How do you actually print the technical materials, then?

For starters, the name gives you a clue about part of how I can handle PEI, PEEK and that family of materials. My print chamber is fully sealed and can be actively heated up to 90 °C. The heat radiates from the side-panel walls of the printer, ensuring an even distribution of the heat. That’s kind of my thing – exacting control over the printing. I can ensure better quality parts because I deliver higher-quality temperature and cooling where it’s needed and when.

Higher quality temperature and cooling? What does that even mean?

So another trick up my sleeve is my print cooling system. I have a turbofan that’s much larger and more powerful that the fans you typically see on a Prusa Research 3D printer. It moves huge volumes of air to quickly cool the plastic as it leaves the nozzle.

Yes I’ve seen the hosepipe attached to the print head – that’s the fan duct, effectively? Isn’t it too long?

That’s the thing! One innovation I have –a protected innovation, no less– is a timing valve that can redirect the air in a matter of milliseconds. Even with a great long hose between the fan and nozzle, I have tight control over the cooling and don’t need to inefficiently blip the fan to keep up.

Precision control = better prints. Understood.

There’s more to it, too. The part cooling air is cycled from within the heated chamber and passed through a filter first, meaning that there’s little chance of particulates in the air contaminating the print.

What about the “regular” materials?

What about them?

Well, are there improvements there, too?

In regular printing, the biggest improvement folks will see over the Original Prusa machines will be in the processing speed. I’m a delta 3D printer, meaning the way I move is better suited to high-speed printing, so I’ll bring the expected performance of those machines up a rung on the ladder of materials. Those machines excel at PLA and easier materials, and are capable of good results with higher temp materials like nylon. I, however, excel at all of those at all sizes, and have the capability of similarly great results in small to medium-size parts from the technical engineering stuff, like PEI.

Will Prusa Research launch its own materials to make use of your abilities?

That’s certainly the plan, but right now I’ll be launching without Prusament PEI or similar technical materials. Development is ongoing but, for now, it’s not there yet. There will be verified materials with profiles in PrusaSlicer, though, so it should be relatively easy to get going at my full potential with materials from other manufacturers.

Oh yeah, PrusaSlicer. How will that work with the HT90?

If you’ve ever used another Prusa Research 3D printer, you’ll know; it’s exactly the same. Despite having different internals from Prusa Research-made machines and firmware built on Klipper, the software side of the experience will be identical to any other Prusa Research product. If connected to your local network, you can remotely manage through your web browser. That, or connect me to the internet and manage me through Prusa Connect.

Uh oh – an internet connection on a device in manufacturing sets alarm bells ringing…

If you need to, you can unplug the Wi-Fi module entirely and sever any connection to the internet.

That is quite a hard line in the sand to draw.

Some companies demand it. While it offers conveniences, an internet connection to the device can also pose a point of weakness in an operation’s network security, so this option gives the best of both worlds.

Anything else we should know?

Large prints from warp and delamination-happy materials like ABS and ASA are my specialty. I’m designed to make the typical difficulties of these materials a non-issue. My high-flow toolhead takes care of that, and if you need to switch up to the technical materials, it’s only attached by magnets. You can yank it off and replace it with the 500 °C toolhead.

That’ll be all. This was weird. I need to lie down.

Prusa Pro HT90 Tech Specs & Price

- Technology: Fused deposition modeling (FDM)

- Build volume: 300∅ x 400 mm

- Print speed: 250 mm/s

- Acceleration: 20,000 mm/s

- Filament throughput: Up to 40mm³

- Max. chamber temp: 90 °C

- Max. bed temp: 155 °C

- Max. nozzle temp: 300/500 °C

- Price: $9,990

The Prusa Pro HT90 is available now.

License: The text of "Getting To Know the Prusa Pro HT90" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

Stay Informed, Save Big, Make More

Stay Informed, Save Big, Make More