Google Arts and Culture and Stratasys are harnessing the power of 3D printing to recreate pieces of history—from monuments to artifacts.

By printing using Stratasys’, a global leader in additive manufacturing, advanced colour and multi-material J750 3D printer, Google’s Open Heritage Project will bring history back to life.

“The Project was to explore physically making these artifacts in an effort to get people hooked and excited about seeing places in a museum or research context,” said Bryan Allen, a design technologist at Google.

“That’s when we turned to 3D printing.”

Through the Open Heritage Project, anyone can explore iconic locations in 3D and discover the tools of digital preservation. You can also download nonprofit CyArk’s work to 3D print the artifacts yourself.

The site offers 3D printable models of historic sites like Berlin’s Brandenburg Gate and Mexico’s Chichén Itzá, along with ancient statues and rock art.

Google Arts and Culture’s project enables historians to re-create artifacts both in the digital world and now the physical world too. They hope it will become easier to raise awareness about the world’s most important artifacts, while preserving them for hundreds of years to come.

“When we talk to arts and culture preservationists, historians, and museum curators, they’re all absolutely amazed by the ability to fabricate these things with such high fidelity via 3D printing technology,” said Allen.

Digitally and Physically Preserving Artifacts

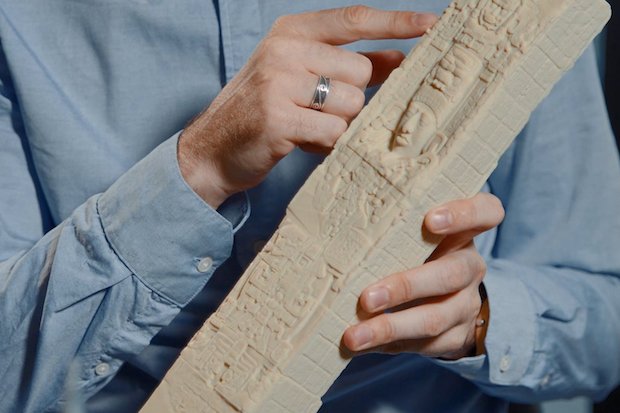

A major undertaking by Google Arts and Culture was recreating and restoring rare plaster casts found in Guatemala in the 1800s. The casts had been in the British Museum’s storage facilities for over 100 years.

After 3D scanning the plaster casts, they were printed on the Stratasys’ J750 3D printing system which can recreate around half a million different colors. The resulting replicas were highly detailed, with a great finish and more robust than the originals.

“The J750 empowers designers to actually achieve their ultimate goal – matching the final 3D print to what is initially seen on the screen,” said Rafie Grinvald the enterprise product director of rapid prototyping at Stratasys.

“Combining rich colours and translucency in a single print, designers and engineers can build models with heightened levels of accuracy and realism, mirroring opaque or transparent structures, and even complex materials like rubber.”

Grinvald adds that Stratasys’ relationship with Google Arts and Culture demonstrates of 3D printing can truly pay off by creating model replicas just like the originals.

Source: Press release

License: The text of "Google Arts and Culture and Stratasys Recreate Historical Artifacts" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.