AI for 3D printing and manufacturing is already here, and it’s growing. It’s how it grows that will be crucial. “We’re just broaching how much AI can impact 3D printing right now,” says Arvind Rangarajan, Global Head of Software and Data at HP Personalization and 3D Printing. There’s plenty of innovation to look forward to, but also reasons to proceed with caution.

Rangarajan says that he has, over the last few years, been developing “an overall AI strategy” at HP for a smooth implementation of AI 3D printing tools. He sat down with All3DP to talk about AI at HP and in the 3D printing industry: where it came from, where it is, and where it’s going.

Maintenance and Usability

With the recent astronomical growth of interest in AI applications, the opportunity for partnership, such as with Nvidia, and investment has been ripe. HP has moved on the trend to implement AI technologies at both the software and hardware levels.

Already, HP is leveraging traditional machine learning approaches, collecting various telemetry data for its predictive maintenance software.

Predictive maintenance is one of the first applications where HP has applied AI, Rangarajan says. The company’s polymer 3D printers – its Jet Fusion machines – have over 30 integrated alarms that can alert users “a few weeks to a month” before hardware failures, allowing businesses to prep and repair on their own terms.

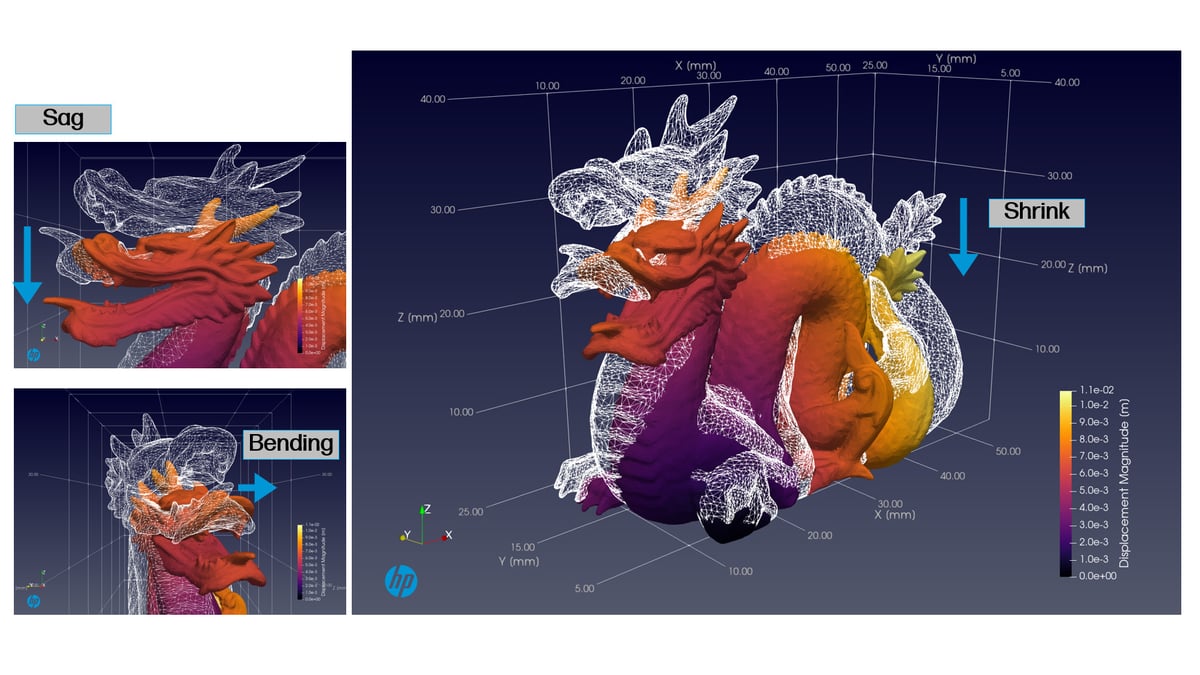

But modern AI solutions are opening the door for HP beyond traditional machine learning techniques, to pursue coveted advancements, such as improved part repeatability with demanding materials like metal. HP is doing this via its endeavors into digital twins: software that – among other things – can use real-time data to simulate the effect of forces on objects. The results are highly tangible; HP’s digital twins help better prepare parts for printing with algorithms that predict and account for deformation.

Now, partnerships with major AI players like Nvidia have unlocked the potential of those smaller datasets. Using and contributing to Nvidia’s open-source Modulus framework, HP has developed the Virtual Foundry Graphnet model: a graph-based deep learning algorithm that enables users to predict part deformation, such as shrinkage, bending, and sag in metal binder jetting applications.

In a July research paper published in the journal Sensors and Materials, HP’s team says its graph-based deep learning approach “achieved a considerable speed-up compared with conventional physics simulation software while maintaining acceptable accuracy levels.” The accuracy levels achieved measured “a mean deviation of 0.7 micrometer for a 63 mm test part in a single sintering step … and a mean deviation of 0.3 mm for the complete sintering cycle.”

“People need a lot more reliability and consistency within builds, across builds, across printers,” Rangarajan says. “So that was a good match in terms of the [AI] technology developing, as well as the needs arising from 3D. That’s when people really started applying AI to 3D printing because it started getting into production. And [users] figured, ‘Oh, I can now use software and the data we are collecting and actually feed a meaningful model that can help enable reliable, consistent production between and across machines.’ “

AI-Aided Design

Though HP’s existing AI-powered predictive maintenance is already making a difference on shop floors, and deformation models are soon to improve repeatability in metal 3D printing, Rangarajan still sees skill barriers like 3D design as the major hurdle to technology adoption that AI is primed to tackle.

The first area to take design on? 3D scanning.

HP and others in the additive industry use “body fitment” tools that leverage 3D scanning to create personalized products – like orthotics and other medical devices. But 3D scanning isn’t quite the plug-and-play solution it may seem when it comes to precision-fit products.

The 3D scanning process creates large point clouds that must be deburred by an experienced 3D modeler before designs can be implemented and models made ready for use. Though the process requires some 3D modeling skill, it’s largely routine. So, HP is working to better automate the personalized design process with an AI algorithm that takes 3D scans and simplifies the data by identifying crucial landmarks in the model, then uses those landmarks to parametrically create personalized designs.

“We create a landmark score, the person-to-person variation, to map into a design that you can quickly provide the customer,” Rangarajan explains. “So, instead of waiting a few hours for it to go to some remote third-party designer where they look at this point cloud and manually design stuff, we can now instantaneously provide the customer with design options while they’re still in the clinic.”

Though 3D scanning appears to be the most immediate way HP is tackling design barriers, it’s not the only way. Generative AI for 3D models, or text-to-3D, is showing promise, too, with HP and its partners already showcasing the technology for large audiences.

At Nvidia’s GTC conference in San Jose, Calif., HP partnered with Nvidia and Shutterstock to demonstrate a full end-to-end text-to-3D model pipeline where attendees could generate 3D models from text live in under a minute.

“Shutterstock’s 3D AI generator enables designers to rapidly iterate on concepts, creating digital assets that HP can convert to 3D printable models through automated workflows,” An Nvidia blog says of the demonstration.

That pipeline automatically handles color mapping, follows parts to ensure stability, and allows users to add a stand if needed, Rangarajan said before adding that HP is taking the next step internally to create its own text-to-3D application. “We can create much more detailed models than what the NVIDIA text to 3D pipeline has by combining different generative AI techniques.”

Material Formulation & Exercising Caution

Though there’s a lot to be excited about over HP’s most visual, and possibly most broadly applicable, work on text-to-3D applications, Rangarajan allays excitement by noting the process is still under development and, despite the company’s internal enthusiasm over the prospects, he makes clear that keeping expectations realistic is vital to the successful adoption of AI tools in industry.

“If somebody over promises what AI can deliver to a process and it fails, it will affect every single OEM in the market,” he says. “This has happened in additive before. People have over promised and messed up the potential for others who are much more cautious in development.”

In some ways, this has already happened in AI, too. Assertions of data misuse from other AI application developers have marred conversations around data privacy and AI, Rangarajan laments, making it more difficult to assuage customer privacy concerns while working to collect the datasets needed for applications that could be dramatically advantageous to the 3D printing industry. Material formulation and development is one of them, which Rangarajan believes to be a driver for 3D printing adoption.

“We have to figure out the right operating mechanism in terms of data ownership, data, privacy security, to be able to collect this data in an anonymized way from our customers to really speed up how we can improve and optimize the [3D printing] process,” he says. “The cycle to develop and refine a process today, even for polymers could be a few months, for metals it’s years. Two years, three years for you to optimize. But if you can collect this data, it could be weeks. For polymers, it could be days.”

AI material formulation is a pillar of Rangarajan’s AI strategy that he expects to see implemented in the next three to five years, but it won’t happen without trust between manufacturers like HP and their users.

Fortunately, plenty of HP’s AI solutions are already on the way, and Rangarajan’s benchmark for success before release is high. He speaks of the importance of the applications “beating experts” to be viable. “One of the things that I look for from an AI solution is to give non-trivial insights,” he says. “So, if an experienced user of HP Multi Jet Fusion technology would have never made that decision, and AI is helping them make a decision, that’s improving their process.”

A high bar to look forward to from the company’s new and upcoming AI applications.

License: The text of "HP is Already Implementing AI in a Big Way, But There’s More to Come" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

Stay Informed, Save Big, Make More

Stay Informed, Save Big, Make More