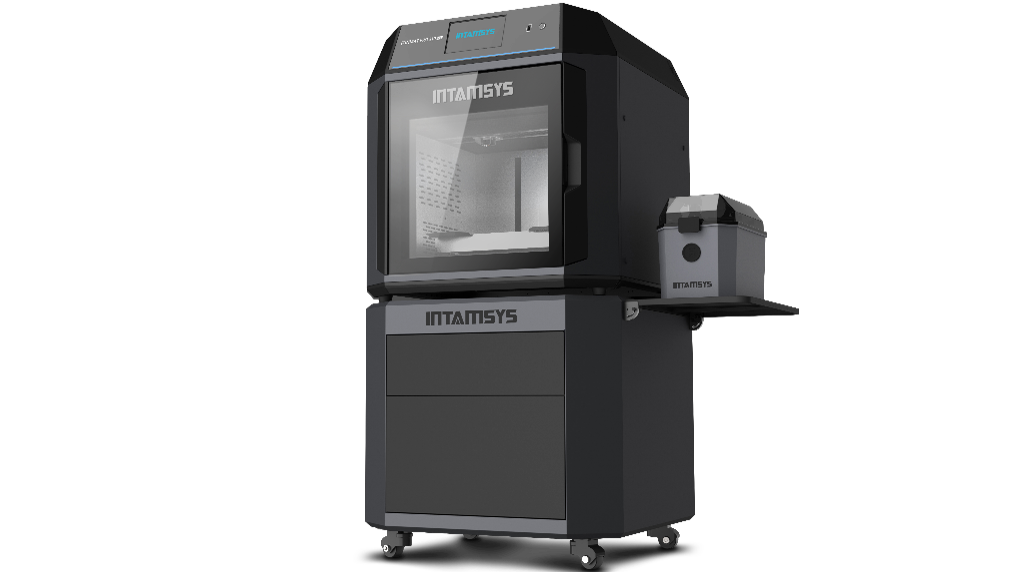

INTAMSYS, a leading innovator in industrial 3D printing, today introduces the FUNMAT PRO 310 NEO, a revolutionary industrial high-speed FFF 3D printer designed for direct industrial applications and small batch production.

The Perfect Balance of Speed and Quality

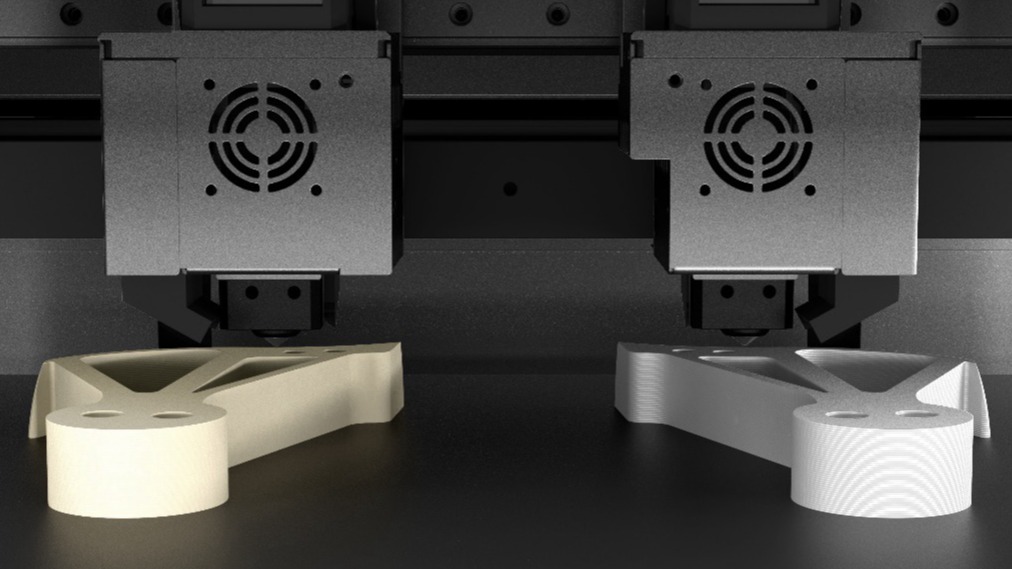

The FUNMAT PRO 310 NEO achieves remarkable printing speeds, boasting a daily production capacity of 500-1000 g – and exceeding 1000 g per day in mirror/duplicate printing modes, due to the printer’s newly developed high-speed architecture.

With more than 240,000 hours of production-level high-speed printing testing and more than 30,000 parts printed, the FUNMAT PRO 310 NEO delivers consistent, industrial-grade quality and performance, even at high speeds. Its optimized control algorithms and material process packages ensure strict control over surface finish and dimensional accuracy, guaranteeing reliable, continuous production.

There are currently eight types of material printing process packages for PC, PC-FR, PC/PBT, ABS-HS, PA12-CF, PPA-CF, PPA-GF and PLA. Given that PC especially is notorious for being difficult to print, especially at high speeds, the FUNMAT PRO 310 NEO could fill that industrial space in the market.

A Reliable Guarantee for Full-Format Printing and High Strength

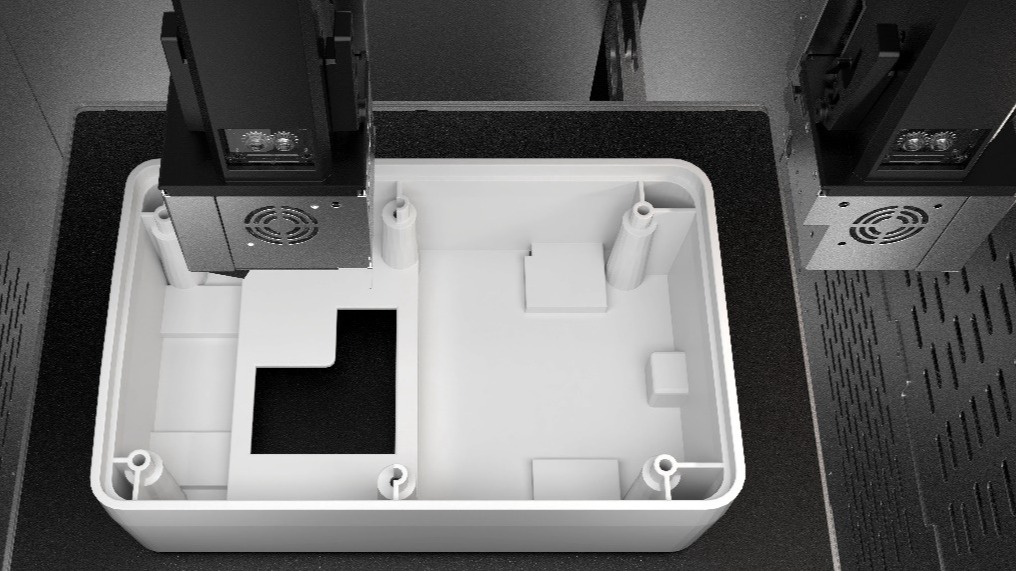

The FUNMAT PRO 310 NEO provides a uniform heated chamber of up to 100 °C, which will reduce thermal deformation and shrinkage to avoid warping. It guarantees full utilization of the build volume, enabling reliable printing at a full size of 305 x 260 x 260 mm, where the print size equals the build size.

Additionally, maintaining a uniform high chamber temperature can enhance interlayer adhesion, resulting in benefits such as three-times greater tensile strength for ABS, and improved mechanical properties for PC and PC-ABS – ensuring repeatability and consistency that is ideal for mass production and the manufacturing of end-use parts.

Material Versatility for Diverse Industrial Applications

The FUNMAT PRO 310 NEO comes equipped with eight high-speed material process packages, each rigorously tested with various models over extended periods. Notably, the FUNMAT PRO 310 NEO boasts a nozzle temperature of 350 °C, enabling the printing of high-performance materials like PPS and supporting flexible materials like TPU95A.

The printer shows the exceptional printing capability with high-performance, flexible, and engineering-grade materials (including PC, PC-FR, PC/PBT, PC/ABS, ABS-HS, PA12-CF, ABS+, ASA+, PA6/66, PA6-CF, and TPU95A) without changing the nozzle. It also boasts compatibility with PC-FR, which has flame-retardant properties for use in sectors like rail transportation; PC-ABS, which is ideal for long-term outdoor automotive applications; and PC/PBT for electronic manufacturing.

INTAMSYS is dedicated to expanding its material portfolio with new high-speed material process packages, which are currently undergoing accelerated testing and will be released soon. Existing users will receive automatic update notifications and enjoy free upgrades.

Furthermore, the IDEX system’s versatility is evident in its four working modes: mirror, duplicate, dual, and support material printing. Support mode printing is especially beneficial when combined with water-soluble or easy-peeling support solutions for complex geometries. The mirror or duplicate modes can also increase productivity.

INTAMSYS adheres to an open material system, and the FUNMAT PRO 310 NEO also supports printing with open-source materials, providing greater flexibility for exploring various printing possibilities.

Enhanced User Experience

The FUNMAT PRO 310 NEO is designed to elevate the user experience. Its advanced auto Z-axis leveling with dual nozzle difference mitigation ensures that you are always ready to print. The printer’s mesh leveling system, with up to 10 x 10 mode, provides real-time compensation and greater accuracy during printing. The FUNMAT PRO 310 NEO also features remote networking capabilities, giving users unparalleled control and monitoring of their printing process.

As an industrial high-speed FFF 3D printer, the FUNMAT PRO 310 NEO meets the demanding needs of high-intensity, continuous production for various clients, including printing service bureaus and industrial companies. It offers a highly efficient and reliable solution for batch production, boosting productivity.

About INTAMSYS

INTAMSYS is a world-leading additive manufacturing company, providing industrial 3D printers, software, materials and printing services. Specializing in industrial FFF technology, INTAMSYS is empowering customers from various sectors including aerospace, defense, automotive, renewable energy, medical, electronics, etc. With branches in Germany, the United States, and China, INTAMSYS maintains a global network of partners, ensuring seamless service delivery worldwide.