Most desktop resin 3D printers on the market leverage Parallel Emission technology. This well-known process works by using a UV LED matrix to project light. The functionality of these LED units play a significant role in the success of the 3D printing job.

However, some feedback reflects that this technology doesn’t always provide enough less lighting intensity which results in unevenness, and broken LED units will easily influence the model’s precision. That’s why users find it challenging to achieve high quality prints sometimes.

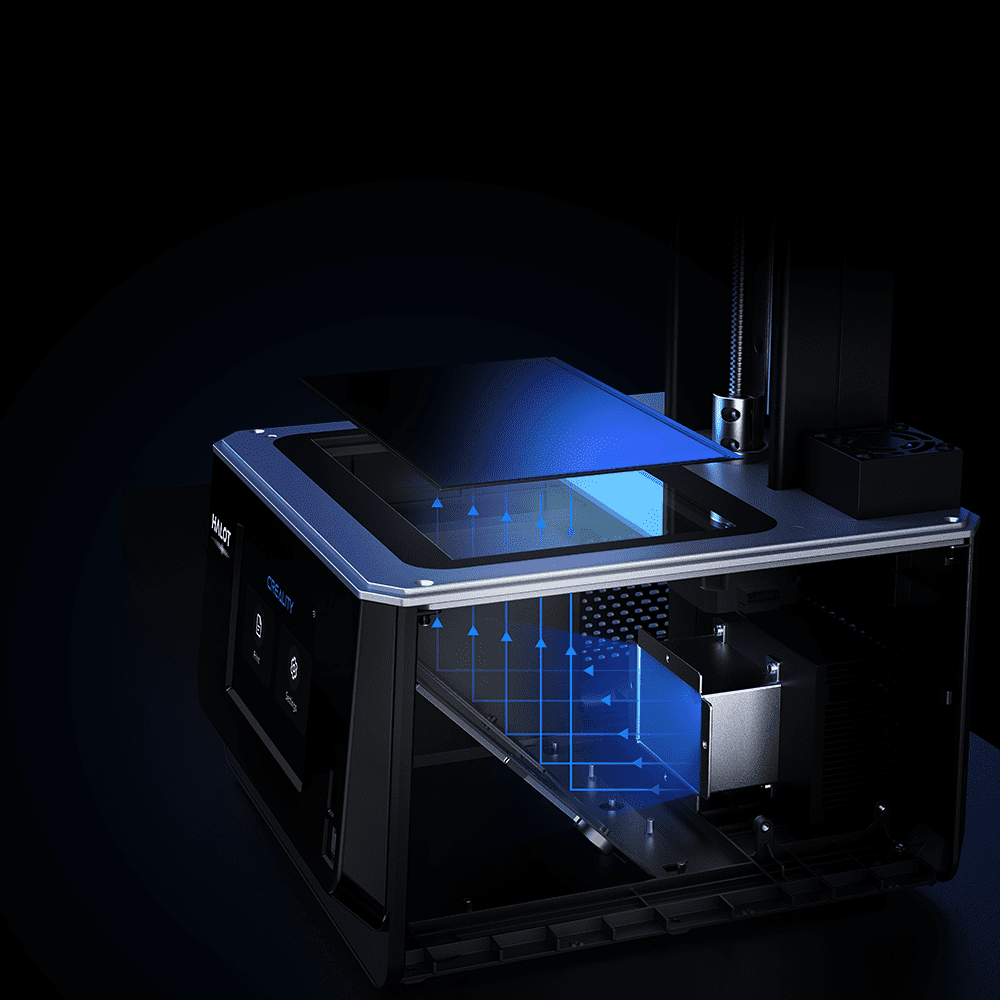

To solve this problem and optimize the user experience, Creality’s R&D team has delved into new resin 3D printing methods and recently emerged with a technological breakthrough. This past year, Creality released a series of new resin 3D printers, all of which have adopted the next-generation Integral Light Source technology. With stronger lighting intensity, remarkable lighting evenness and ultra-high printing precision, Integral Light Source technology is developed to take resin 3D printing to the next level.

Why Integral Light Source?

Lighting Evenness

With Parallel Emission technology, if there are broken units in the matrix, the print will be negatively affected by the uneven lighting. Furthermore, the light intensity at the corners is not always consistent with other areas, which can also cause issues with print quality.

Creality’s self-developed Integral Light Source, on the other hand, was built using the principles of reflection and refraction. From a component standpoint, the process includes five LED units with four emission chips. This technology ensures at least 90% evenness with 6000uw/cm² lighting intensity. It doesn’t matter if a LED unit is broken, Integral Light Source will still provide a more stable printing condition for users.

According to the testing data acquired by the Creality team, the lighting evenness of its next-generation Integral Light Source can reach up to 93.5%, while the Parallel Emission model only achieves 51.1%. The remarkable evenness offered by Creality’s technology makes it especially reliable for high-precision 3D printing of models with glossy surfaces.

Lighting Evenness Differences (Visual Comparison)

Accuracy

The new series of Creality resin 3D printers powered by Integral Light Source technology vastly improve printing accuracy. Take the following T0 model, showcased below, as an example. For a 60 x 60 mm model, the one printed with Integral Light Source Technology turns out to be 59.91 x 59.93 mm with an accuracy of 99.73%, a stark improvement over the one printed with Parallel Emission Technology.

The new generation Integral Light Source technology has been integrated into the Creality HALOT ONE series, an array of resin 3D printers including HALOT ONE, HALOT ONE PRO, and HALOT ONE PLUS.

Let’s take a close look at one of these new machines: the HALOT-ONE PLUS. As a new resin 3D printer launched in 2022, HALOT-ONE PLUS impresses users with its high precision, intelligent functionality and ease of use. It’s equipped with a 7.9” 4K Mono LCD touchscreen that enables makers to print their favorite models, characters, tools, etc. Even micro-pores and micro-columns can be vividly printed, bringing imagination into reality with incredible surface details.

In addition to 3D printing objects like character models and tools, the Integral Light Source technology is also ideal for those in the jewelry industry. Up to 92% lighting evenness allows users to print out support structures of 0.1-0.3 mm for models with complicated structures. The technology behind the HALOT-ONE PLUS lends itself to higher precision and enhanced speed, vastly improving the 3D printing experience.

Powered by the new generation Integral Light Source technology, the HALOT-ONE series will surely bring some welcomed surprises to users. Anyone who is interested in learning more or purchasing one of these cutting-edge resign 3D printers can purchase one on Creality’s new online shop.