Multicolor 3D printing continues to grow in popularity, with companies like Bambu Lab taking it mainstream and leaving other desktop 3D printer manufacturers clamoring to release competitive solutions.

But long before Bambu Lab, Prusa Research pioneered a device for its i3-series machines that offered exactly what we know to be modern desktop multicolor 3D printing.

Currently on its fourth iteration as the MMU3, earlier versions of Prusa’s MMU suffered from reliability issues that more or less stunted the device’s ability to be anything more than a fringe addon for anyone but the most dedicated to the pursuit of multicolor printing. By the company’s admission, the conditions for the MMU to perform reliably were too stringent and unforgiving. As such, the MMU never quite took off in the way that multicolor 3D printing now has.

With the MMU3 (from $299), the outlook is brighter with Prusa seeming to have turned a page on that particular chapter. At least, from the hundreds of hours we’ve been running it, the MMU3 is as reliable as the MK4 3D printer it hooks up to. And you can now get one bundled with the printer ready-built, saving on hours of assembly time.

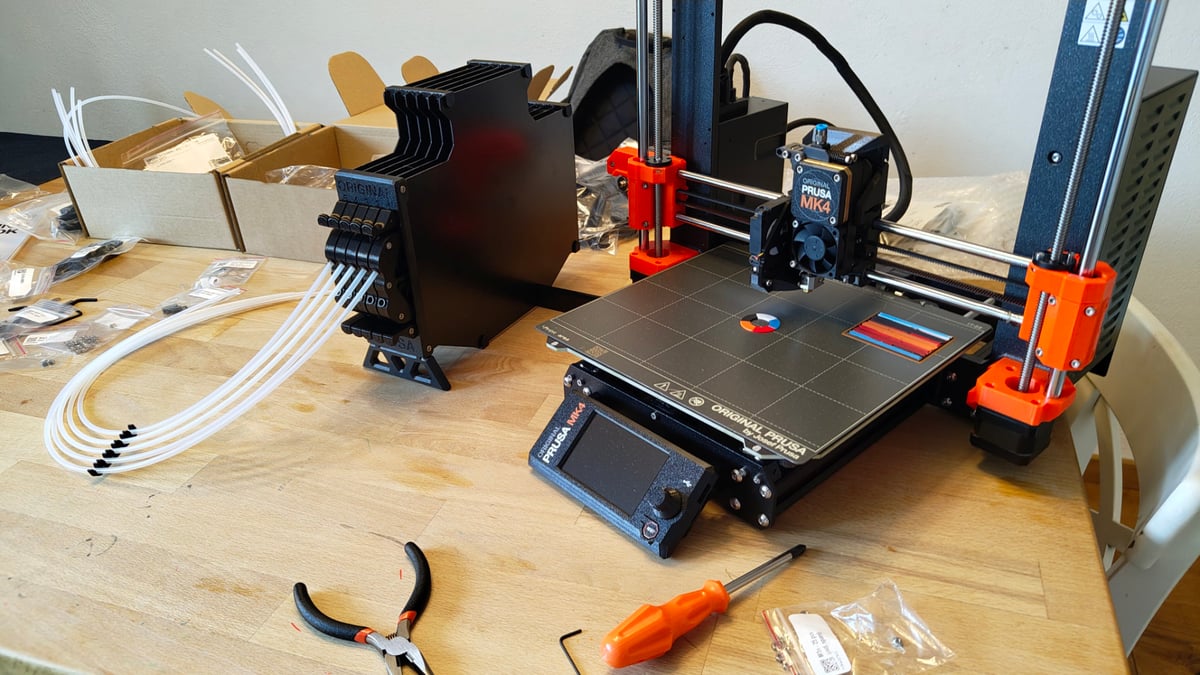

All3DP was sent one of the pilot run of assembled MMU3 and MK4 3D printer (this happened shortly before the MK4 was superseded by the MK4S) bundles. It’s worth noting here that – as with the Prusa XL – assembled doesn’t mean plug-and-play. In the MMU3’s case, there can be up to an hour’s worth of busywork assembling the strongly recommended (but ultimately optional) filament buffer before you’re good to go. If you buy the MMU3 and MK4S bundle as a kit, there are many hours of assembly ahead of you.

At A Glance

- Price: $299 (kit), $359 (assembled)

- # of Filaments: Five

- Upgradable from MMU2: Yes

- Compatible with: Original Prusa MK4S, MK4, MK3.9S, MK3.9, MK3.5S, MK3.5, MK3S+

There are a multitude of upgrade paths for the MMU3 – Prusa Research maintains an MMU3 compatibility chart to help you wrap your head around what you need.

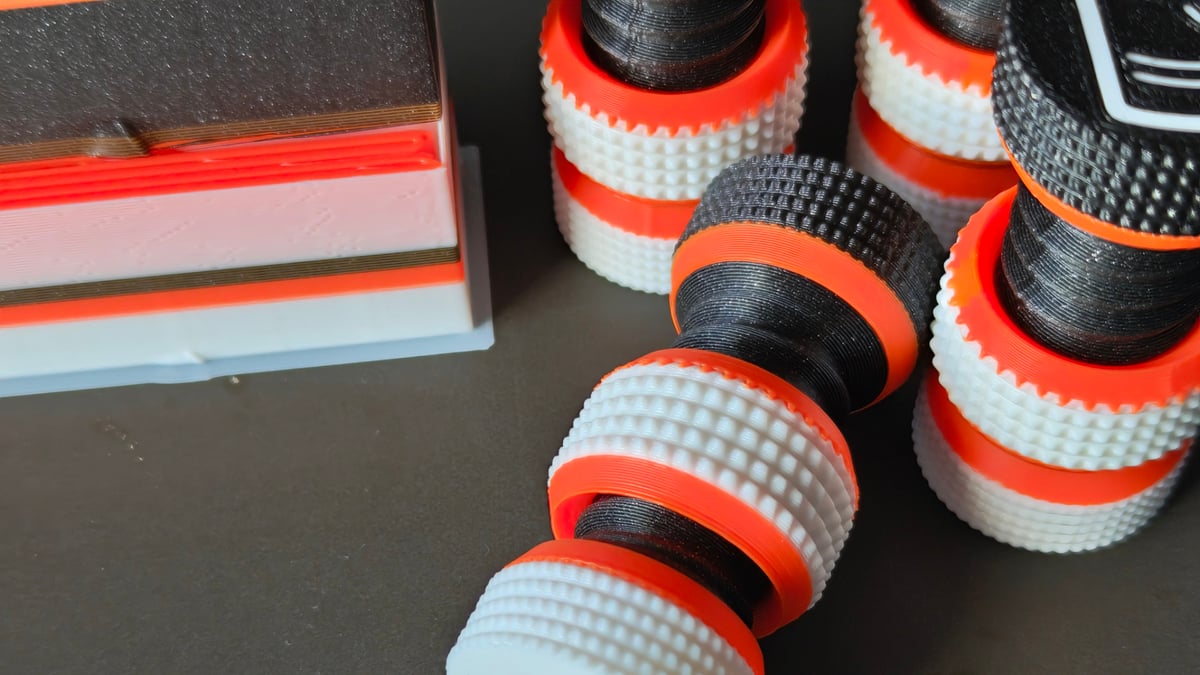

Unboxing the assembled, bundled MK4 and MMU3, the main MMU3 device comes fully assembled. This block of motors with a barrel-shaped idler-selector for the multitude of filaments is held onto the printer’s frame by gravity.

For users purchasing the MMU3 as an upgrade for their printer to assemble for themselves, there would be some intrusive rewiring needed in the printer’s control box to hook up data and power cables, but this is all already done for you with the bundle.

What Sets the MMU3 Apart?

There are obvious aspects of the Prusa MMU that separate it from Bambu Lab’s AMS and the Anycubic ACE Pro. For one, it doesn’t make a mess of your desk with purge squiggle “poop” from every color change. Instead, the MMU3 focuses its cleanliness regimen on a purge tower, which Prusa claims is less wasteful than competing systems. The overall effect is tidier, for sure. Comparing my goofy-looking Test Toast(™) print saw a purge savings of some 300% compared to the Bambu Lab A1 and AMS Lite. You have the flexibility across all systems mentioned to do things like purging to infill to cut back on the waste, too.

The Prusa MMU3 can print with five different spools of material compared to the four offered by Bambu Lab, Anycubic, and, soon, Creality. The obvious benefit here is the possibility of five colors in your prints or a dedicated support material slot with four remaining colors at your disposal.

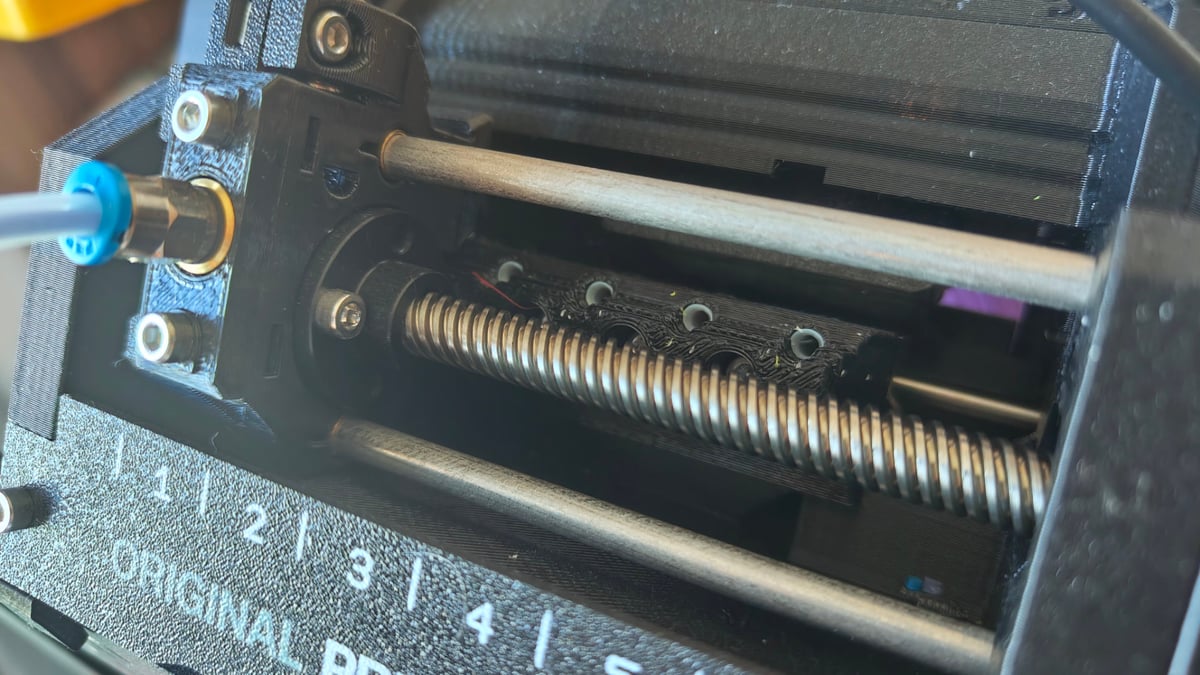

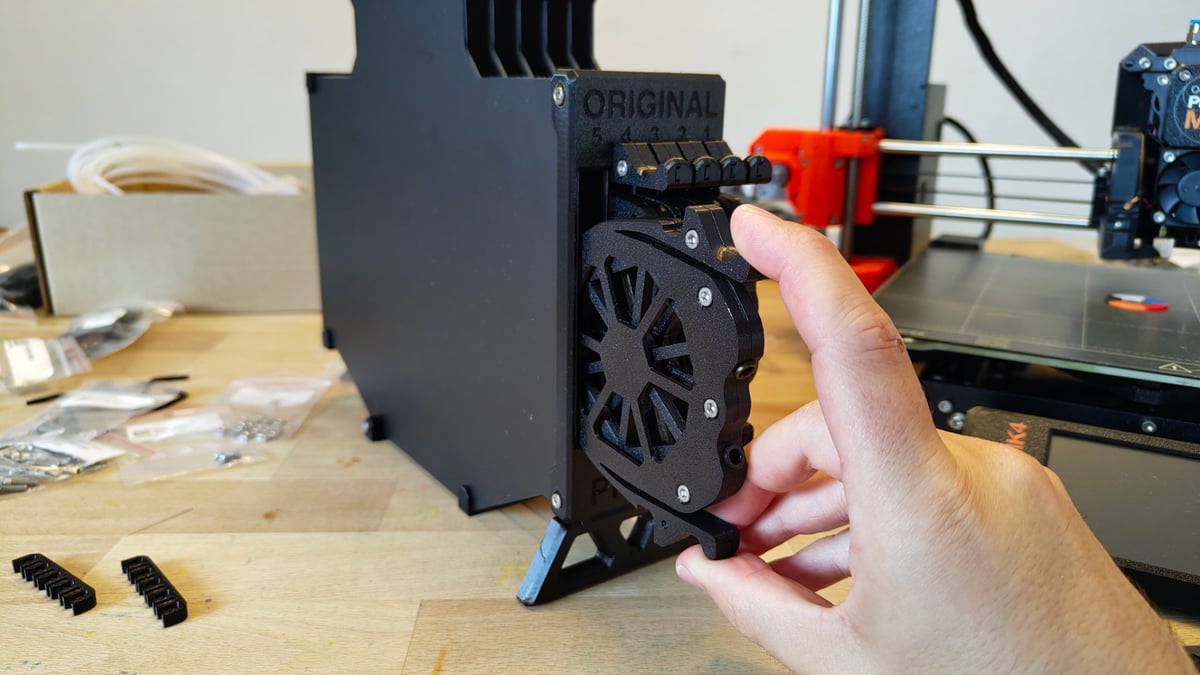

The way the MMU3 handles the filament is a step removed from other multi-material units on the market. As with its previous generations, Prusa’s MMU3 uses a rotating barrel-like idler to grab and feed filament through the MMU, and a selector slides back and forth to line up the print head’s filament guide tube, effectively completing the filament path from spool to hot end. Rather than having the filament converge at the print head, they remain separate and individually end at the MMU.

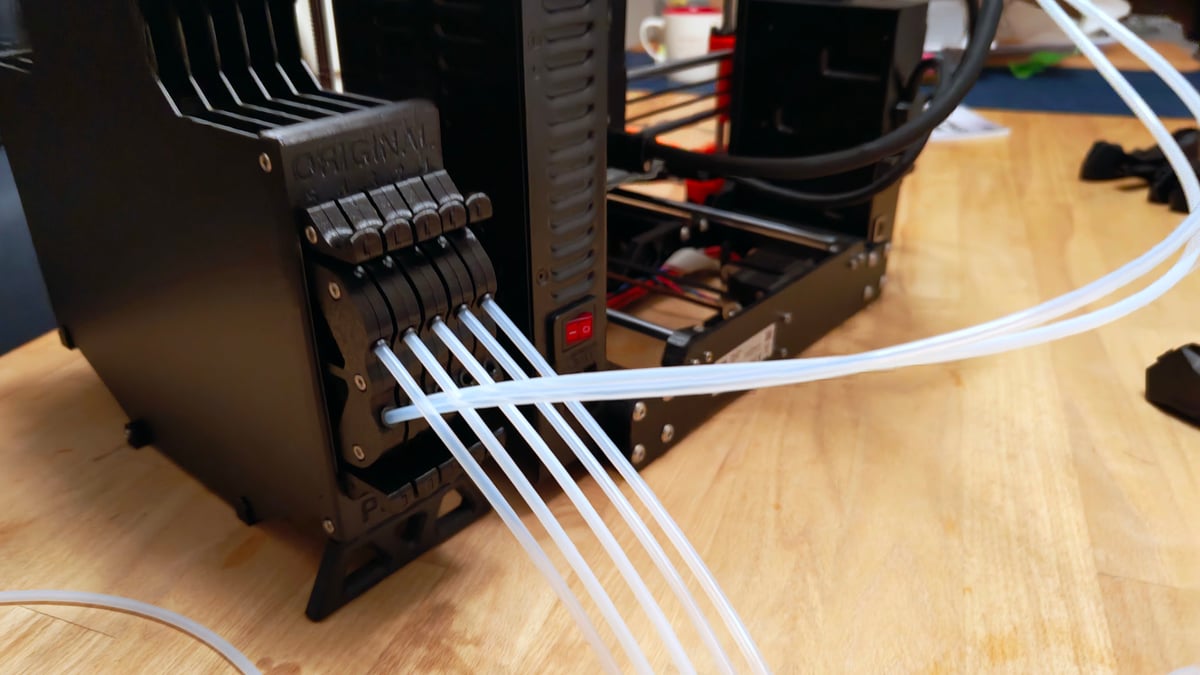

Unlike single-nozzle multi-filament systems that rewind the spool at filament change and maintain a small buffer for smooth extrusion, the MMU3 instead uses a large filament buffer before the selector that lets it make rapid loads and unloads. At filament change, filament from the hot end quickly retreats to the MMU device, with the slack appearing in the filament buffer that sits next to the printer. Neatly contained, and accessible via the removable cartridges, it’s a pretty elegant solution to the speed and mess of in-print filament changes.

A consequence of this design is that the initial filament loading up to the MMU unit (spool to buffer and buffer to MMU) is an entirely manual process. It’s not difficult, mind, nor fiddly. Honestly, it’s quite satisfying handling the filament cartridges and slotting them into place.

It’s things like this that show a fork in the road for the MMU3 as a technical, hackable tool and other contemporary multi-filament units prioritizing simplicity.

Take auto-filament reloading, for example. Some systems use a toggleable option that will automatically pull identical materials for continuous printing. the MMU3 doesn’t do automatic reloads. Instead, it can link up any spools; the key difference is that Spool Join is not an automatic process, and can only be set on the printer at the beginning of a print. Overall we’d argue Prusa’s system offers far more flexibility, letting you configure even multiple separate streams of reloads for a multicolor print.

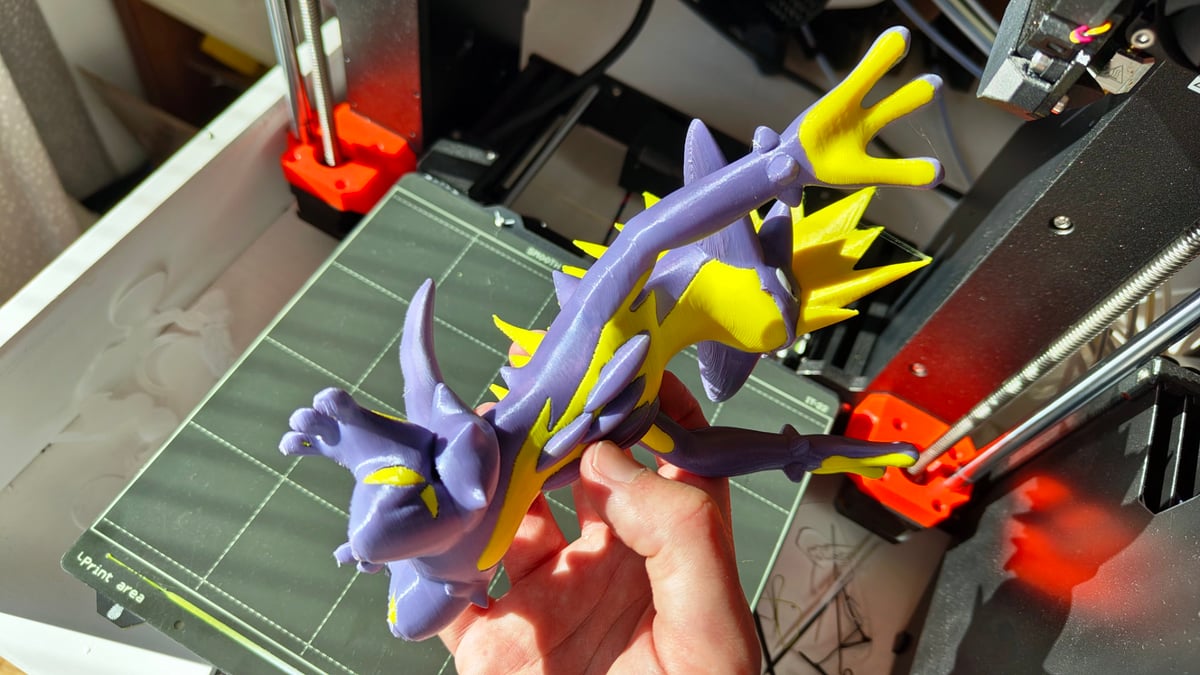

Color and Printing

Setting up your models for multicolor printing with the MMU3 is a doddle using the inbuilt color painting controls in PrusaSlicer. There you can use brush-style tools to paint across the mesh of your model or use the triangles of the mesh to create separate sections for separate filaments. These tools are the basis of color printing for slicers that derive from PrusaSlicer, so logically there will be familiarity here for anyone who has used Bambu Studio or Orca Slicer to set up a color print.

Of course, multi-part objects is another way to mix and match colors and materials in a print, too. The MMU3 is largely bound to the same limits on multi-material printing as other single-nozzle style systems, though using dedicated support materials like PVA is comfortably achievable.

The prints are some of the cleanest we’ve seen (Source: All3DP)We have minor grumbles with the logic of some things, like color painting by layer height not residing with all of the other color painting options. Likewise not being able to designate a dedicated support material without having to use the soluble-specific print quality profiles. These are small beer, though, we know. Once you know where these things are and how they work, it’s not a problem.

And we get it. Multicolor was never Prusa’s primary selling point for the i3 3D printers, the system works well within the company’s thing of the 3D printer being, first and foremost, a reliable tool for making. But now the MMU3 just works too, maybe it should be.

For existing Original Prusa 3D printer owners, plus those of you taking particular care in the amount of waste your printer generates, the MMU3 is a no-brainer of an upgrade for your printing.

Editor's note: We tested the MMU3 using an Original Prusa MK4, which has now been superseded by the MK4S. While we'd expect the performance of the MMU3 itself to be identical on the MK4S, by default Prusa ships that printer with a standard Nextruder nozzle instead of the base MK4S' high-flow CHT nozzle, citing less efficient performance with waste material when printing.

License: The text of "Printing More with Less; Hands-on With the Prusa MMU3" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.