For one of the biggest names in the 3D printing community, Prusa Research founder Josef Prusa manages to keep a relatively low public profile.

Though the creator of the MK3S printer attends conferences and maker events to connect with his fans and customers, ranks as one of Forbes’ 30 Under 30, and has led Prusa Research to a spot on Deloitte’s Technology Fast 50, he somehow still doesn’t have a Wikipedia profile.

All of this begs the questions: Who is this Mr. Prusa and how did he manage to create one of the biggest 3D printer brands in the world?

Growing up, Josef Prusa says he was always interested in technology, but more into computers and programming than anything else.

His father owns a furniture company and his mother was a hairdresser, though she later started to work in the family business. So, just as his father had, Prusa wanted to build a company and create something, but, he recalls, “I didn’t know what my field would be when I was little.”

He thought he would take over the family business after his father retires, but says, “life took me on a different path.”

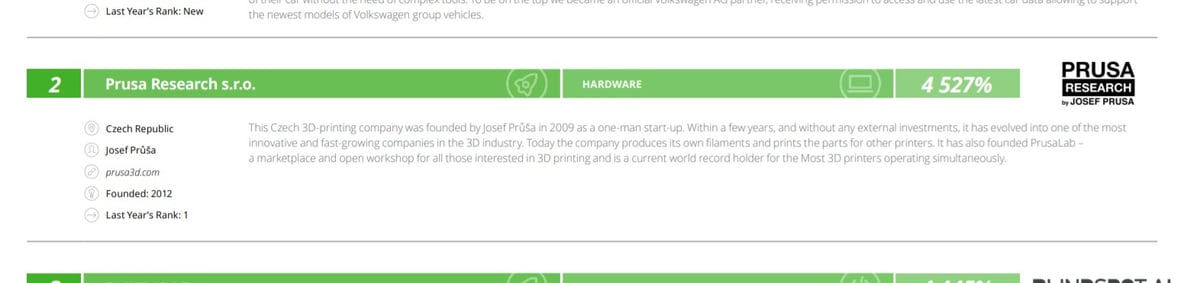

In 2012, that path led him and his brother Michal to found Prusa Research, a company that’s sold more than 200,000 printers and reports enviable revenue growth year after year.

The company offers a host of eponymously-named products including its own filament, Prusament, which has 13 extrusion lines and will be getting more. It also has the Original Prusa i3 MK3S, its most popular machine, the Original Prusa Mini, a smaller and more affordable version of the MK3S, and an MSLA resin 3D printer, the SL1, which ties in with an optional Curing and Washing Machine.

But, despite his company’s success, Prusa seems like a fairly lowkey guy.

He’s known for wearing black T-shirts that say “Everyone is a maker only I am a printer Prusa,” thick-rimmed black glasses, a flat cap, and sporting a beard.

And asides from his sartorial choices, the 30-year-old Czech Republic-native is known for being an almost larger-than-life figurehead in the 3D printing community.

His experience with 3D printing began while he was a student at the University of Economics in Prague. He had a lot of free time, so he and his brother started to get into DJing. He wanted to build better music controllers, and so he turned to 3D printing to do so.

This led him to the RepRap project, a community initiative begun by University of Bath professor Adrian Bowyer to create an open-source 3D printer that can replicate many of its components and consequently drive down costs.

Prusa ended up improving the design and, in doing so, created the Prusa Simplified Mendel.

A combination of university starting to “suck a lot” and the increasing popularity and demands of his efforts making 3D printers resulted in Prusa quitting university to focus full time on 3D printing.

“Obviously (my family) didn’t like it, but they were supportive,” recalls Prusa. “You have to keep in mind that back then, 3D printing wasn’t as known as it is now,” adding his family probably wondered “what’s this weird hobby of his?”

The “weird hobby” paid off, and owning a Prusa 3D printer has come to be a badge of pride amongst many makers.

It’s difficult to talk about Prusa the man without talking about Prusa the company.

“I would say me and company are pretty much fused. I mean, I wonder what would happen if I would leave the company. I don’t think it would survive,” muses Prusa, adding with a laugh, “I don’t know how to do anything else other than 3D printers so I would probably not survive for long either.”

Not since Bre Pettis was at the helm of MakerBot has a 3D printing company head had such a public profile and one that feels inextricably tied to it.

“I think it’s very important that people can see somebody behind the company,” says Prusa. “Because if you say ‘Creality,’ it’s just a company. If you say ‘Ultimaker,’ it’s just a company. So people are much, much closer to the company and we – obviously – like to be part of the community.”

But he admits that being the public face of the company comes with its downsides.

“I used to travel 20, 30 times a year and it is really taxing on me. It is impossible to have a normal sleeping schedule,” says Prusa. (He also says he doesn’t have much time for his hobbies, which include DJing and FPV drones, which he just started getting into during the Covid-19 lockdown.)

“It’s also a big responsibility because if we mess up something I get the blame and I get hate mail.”

Prusa seems committed to honoring the company’s humble open-source beginnings from the RepRap project (he even has an open hardware tattoo on his forearm as a reminder).

“It is such a shame that a lot of people take from the RepRap project but none of them give back,” says Prusa. “Basically most of the FFF printing companies that started in the last five years are using the stuff we created 10 years ago and they don’t even acknowledge it. So it is my personal mission to have a RepRap as the best printer.”

Thus far, Prusa seems to be achieving exactly that. When the Original Prusa i3 MK2 was released in May 2016, it received rave reviews and the follow-up, the MK3, was similarly lauded by the community (All3DP included).

Prusa most recently earned praise for spearheading an initiative to design and produce personal protective equipment (PPE) to help reduce the spread of Covid-19.

The company designed an open-source face shield (now known as the Prusa PRO Face Shield) which anyone can print at home on their own personal printer, or even in a more professional setting, and donate to frontline workers to help protect them during the pandemic.

The shield has a CE certification and follows European Union regulations and Prusa is offering to help anyone in the EU looking to manufacture their design in large quantities. They can also apply for an Own Brand Labeller certification from Prusa and the company will cover the cost of it.

It’s a far cry from the early days of the company, where Prusa and his brother handled all aspects of the business. Over the years, a typical day for him has completely transformed from that, to “meetings, meetings, meetings, meetings, meetings.”

But he credits that early immersion and knowing a little bit of everything, with his ability to run the company today.

“It’s important in each individual field to hire people who are much better than you,” he says. “That is what is pushing the company forward, but I keep knowledge of all of the basics and all of the fields.”

Prusa calls his role “the glue that holds all of the people together” and says he sets the path of the company, furthers the popularization of 3D printing, cares for the community, consults with people, and still comes up with new ideas for what the printers should do.

As for what’s next, Prusa says the company will be releasing a resin line to complement its SL1 resin 3D printer. Additionally, a long-standing saga with print bed sheets will be addressed with the release of an all-new sheet that combines the smoothness of PEI with the strength of the textured powder-coated sheets.

“We already have set up a team for making our own resin in house,” says Prusa. We have the lab basically built for it, so that will be hopefully starting in the upcoming months.”

The company will also be releasing its larger-format 3D printer, the Prusa XL, in the near future and is ambitiously trying to become completely self-sufficient.

“We want to try (to produce) basically every part, including the motors,” says Prusa. “I’m not saying that we’ll succeed, but we want to try so we’re not dependent on the suppliers.”

And as for his future at the company, Prusa says he has no plans on selling it or quitting.

“I realize in these times of building startups just for selling them, we are the weirdos,” he says. “We are building the company for longterm and the possibility of passing it onto our children.”

License: The text of "Unboxing Josef Prusa: Meet the Living Legend" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.