As manufacturing technology becomes more capable and accessible to the masses, it has spurred an evolution of how medical professionals think about and ultimately create life-changing devices for patients.

For instance, we’ve seen 3D printing widely used to create prosthetics and devices for disabled patients. In certain cases, subtractive processes like CNC machining are the right technique for the job.

Junia/HEI, a renowned training program for engineers, recently commissioned 3DEXPERIENCE Make, the 3D printing and manufacturing service by Dassault Systèmes, to help create a motion exoskeleton project. The project was envisioned when the engineering team thought about how they could help disabled children walk again.

While various clients have leveraged the expertise and wide-ranging manufacturing network to obtain professional 3D printing services, when necessary for a certain project, 3DEXPERIENCE Make has also connected customers with CNC machining.

This motion exoskeleton project serves as an example of how the manufacturing service goes above and beyond to deliver top-notch results to their global client base. After conceptualizing the design, Junia/HEI worked closely with 3DEXPERIENCE Make to manufacture the exoskeleton project.

Here’s how the project was thought through and ultimately created with the help of a manufacturing service provider.

Junia/HEI and 3DEXPERIENCE Make Bring a Motion Exoskeleton Project to Life

The concept for the project came a few years ago, when a father of a disabled child approached Junia/HEI engineers about helping his daughter walk again. While reflecting on solutions to this heartfelt proposition, the team came up with this motion exoskeleton project.

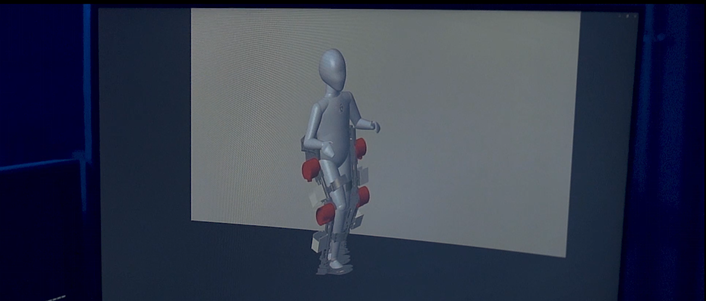

This specific exoskeleton was a functional structure designed to be worn on a person’s limbs. A fully mechanized device, the exoskeleton assists in movement and certain tasks that disabled people often struggle with, such as carrying heavy items or simply re-learning how to walk normally again.

And so, a team of technicians, mechanical engineers, biomechanical engineers and clinicians collaborated to design the exoskeleton. The group utilized Dassault Systèmes’ SOLIDWORKS, an industry-standard CAD design program, to conceptualize the parts of the project.

One of the many benefits of using SOLIDWORKS is its built-in connection with the 3DEXPERIENCE Marketplace, an online ecosystem from Dassault Systèmes that connects designers with qualified industrial service providers including fast and reliable manufacturers.

In the software, users can access the 3DEXPERIENCE Marketplace and select the part they want to create, down to the very material and manufacturing process. Handling the entire collaboration online, the engineering team found it convenient that they could communicate their needs directly through the marketplace. On top of that, they were able to compare costs with different services and ensure that exoskeleton was manufactured exactly how it was envisioned.

“When we do a project, sometimes we need to machine metal parts. But as students, we don’t have much connection with manufacturing companies,” said Laurent Peyrodie, a lecturer-researcher at Junia/HEI. “With the Make service on the 3DEXPERIENCE Marketplace, we can choose manufacturers worldwide and manufacture our project parts very quickly.”

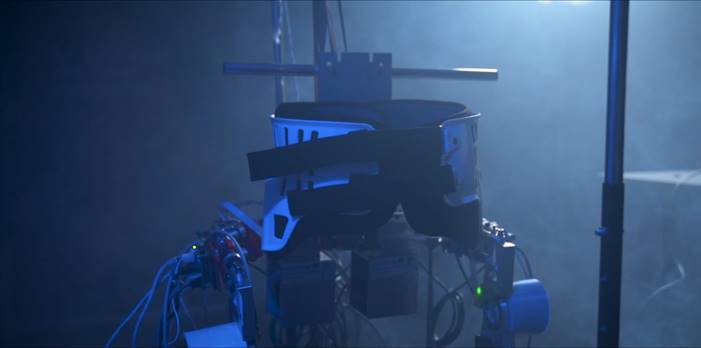

For the exoskeleton project, Junia/HEI first utilized 3DEXPERIENCE Make to validate the design via 3D printing. After ensuring the viability and accuracy of the design, the engineering team sent off the design to get CNC milled from metal and aluminum.

The partner involved for this project was Get It Made, an industrial manufacturing solution with a wide network of manufacturers. Get It Made was able to provide an affordable price to the engineers, ensuring that the parts were produced with quality and delivered with speed.

It took just two to three weeks for all the parts to be delivered and assembled. The team integrated motors to the exoskeleton, which is directed via control boards. The resulting project is an incredible moving structure that can handle pre-determined walking trajectories.

Watch the video below to learn more about how this incredible project was conceptualized and ultimately brought to life – thanks to 3DEXPERIENCE Make.