It didn’t take long for Marcus Ibarra, engineering manager at American parts supplier Dayco, to convince upper management to invest in professional 3D printing. They weren’t very familiar with the technology, but the numbers spoke for themselves: an estimated $100,000 in savings over traditionally tooled aluminum parts in the first year alone.

Dayco’s adoption of additive manufacturing started with a question engineers like Ibarra ask themselves often: There’s got to be a better way?

Bringing a Unique Tool to Life

Ibarra runs the parts assembly shop at Dayco, a company that designs and manufactures engine parts, among other things, for automotive and industrial applications. The Dayco parts that Ibarra needed to assemble included rubber tubes going in different directions. Each assembly had to fit perfectly into end-users’ engines, but ensuring that every assembled product matched federal guidelines down to the millimeter wasn’t going to be easy. Using traditional measuring equipment, Ibarra thought, would take far too much time.

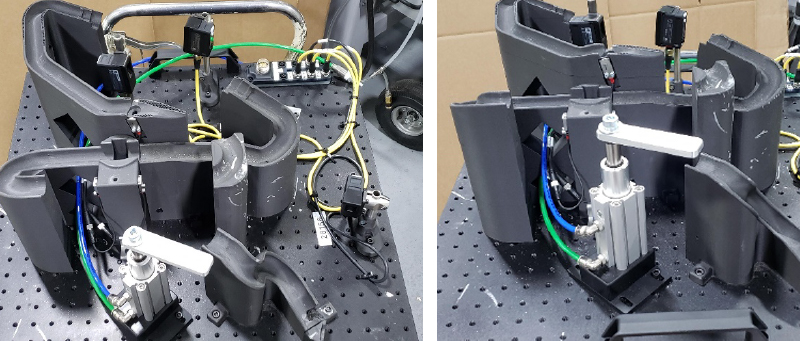

“What we needed was a custom profile gauge,” says Ibarra. This gauge would be a holder that would represent the exact space the assembled product would occupy once installed by the end user. “With a gauge, we could see the routing of where the hoses and tubes would sit as well as the other components that are involved in the application.”

The gauge not only had to be precise, it had to be sturdy enough to withstand the wear of thousands of products being thrown at it each day. Aluminum would work well, Ibarra thought. Unfortunately, the cost of his gauge made at a traditional machine shop was quoted at $25,000, and Ibarra needed at least 10 different kinds.

The Spark of a Great Idea

Convinced that his gauge was the perfect solution, but discouraged by the cost, Ibarra was open to new ideas. A co-worker, who was a 3D printing hobbyist, thought maybe 3D printing would work.

In theory, 3D printing could work, but would it have the strength and accuracy Dayco required? Would it end up being just as expensive in the long run? Ibarra set out to learn more.

Proving Additive Manufacturing’s Benefits

“It landed on me to find the solution, so I investigated all of the different methods of industrial 3D printing on the internet,” Ibarra says. “When we were ready to try some prototyping, we worked with a company called 3D Technologies to build models using SLS (selective laser sintering, where powdered plastic or metal is fused with a laser), but the cost was high, around $8,000 to $10,000 each, so I turned to the internet again to find a cheaper method.”

Through his own research, Ibarra learned that SLS and SLA (where powder or liquid resin are laser fused) are great methods for 3D prints that required internal structures or openings. What he needed, however, was a solid piece.

“I need the print to hold a part. I didn’t need space on the inside of the print, so to get it cheaper I looked at the FDM method,” Ibarra says.

FDM (fused deposition modeling) also known as fused filament fabrication (FFF), creates a part by 3D printing layer-by-layer from material extruded through a nozzle.

“Based on my research, we decided to explore the Markforged X7 model that offered what’s called the honeycomb internal structure. I called them in and they did a presentation,” says Ibarra. “They brought in samples and they compared prints they did to an aluminum bracket that they put under stress trying to break it. Their honeycomb structure part was as strong as an aluminum one. I’m not talking about the wear characteristics on the surface, but the strength of the honeycomb part as a whole. This gave us what we needed.”

In addition to the strength and accuracy, the X7 from Markforged was anywhere from a fourth to a tenth of the cost of other SLS and SLA printers, Ibarra says.

“When I looked at the overall cost of the equipment and the timeframe in which I need a return on my investment, I decided to go with the Markforged.”

Turning an Idea into a Plan

With his part solution and a method to produce it defined, Ibarra now had to convince upper management at Dayco to invest in a $90,000 Markforged X7 3D printer.

“I had to go out to all of our machine shops to get quotes on what it would cost to build parts out of aluminum and steel versus using the 3D printer,” says Ibarra. “I identified all the tools I was going to print over a two-year period and presented the costs for traditional machining versus 3D printing. The ROI for the printer was projected within nine months.” Management was thrilled. The company approved the purchase, and Ibarra got to work.

But when Ibarra set up the Markforged X7 and started printing he realized something new. “I didn’t expect to be 3D printing as much as I am, but when I saw the advantages I went ahead and rolled it forward with everything,” he says. “I do so much more now than just profile gauges.”

One 3D Printing Idea Leads to Another

Ibarra assists the company’s design team with prototypes (the ones they don’t need their SLS printers for) and uses the Markforged X7 to print models of new components that his assembly robots need to manipulate.

“I need to know the external features of a part so I can understand how the robots are going to hold the part at the assembly stage,” he says. “So, if I 3D print the part in advance, it saves me on time to design and come up with a method on how to put it together.”

Ibarra has also turned to 3D printing his robot’s custom grippers used to hold parts during assembly. “If I have the gripper machined, it may not work and then I have to have it machined again, which can take weeks. If I can 3D print it at a low cost I can narrow down on the best design faster. I did this a few months ago where we went through 15 different finger designs to come up with the right one to eventually have machined. 3D printing saved me from having to machine aluminum over and over again.”

Ibarra’s printer can run at 100% capacity for months at a time, meaning he needs to rely on others with 3D printers. So he convinced a couple of his external machine shops to buy their own X7s, and now they print parts for Dayco.

Taking into account both the planned and unexpected uses Ibarra found for 3D printing at Dayco, his ROI went from a projected nine months to less than three.

3D Printing Delivers Competitive Advantage

Dayco’s success story isn’t just about finding a lower-cost alternative to machined parts.

“It’s a huge step forward in that we’re able to get to production level status faster and with less cost,” says Ibarra. “When providing a quote to customers, I can reduce my lead times down significantly.”

At Dayco, it took the spark of an idea, the passion of a dedicated engineer, and the faith of upper management to transform company operations and get one step ahead of the competition.

License: The text of "Markforged X7 Case Study: 3D Printing Stronger Material" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.