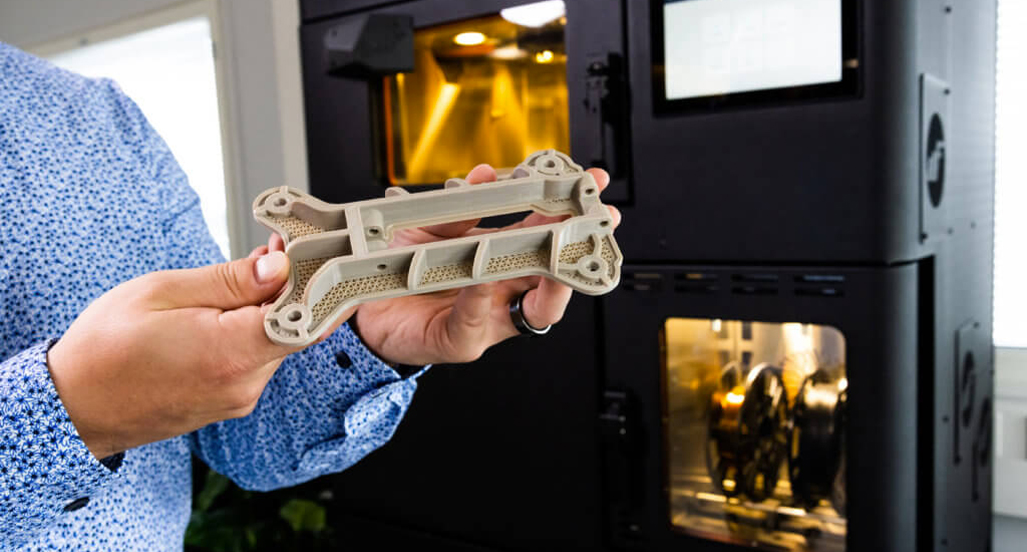

“Make it Right. Every Time.” It’s a goal most professional 3D printer makers are striving toward as they work to convince industrial manufacturers that this technology is dependable.

For miniFactory, the Finnish manufacturer of high-temperature FDM 3D printers for industry, this isn’t just their latest advertising slogan but rather the claim of their new quality control software inside the new Ultra 2 printer.

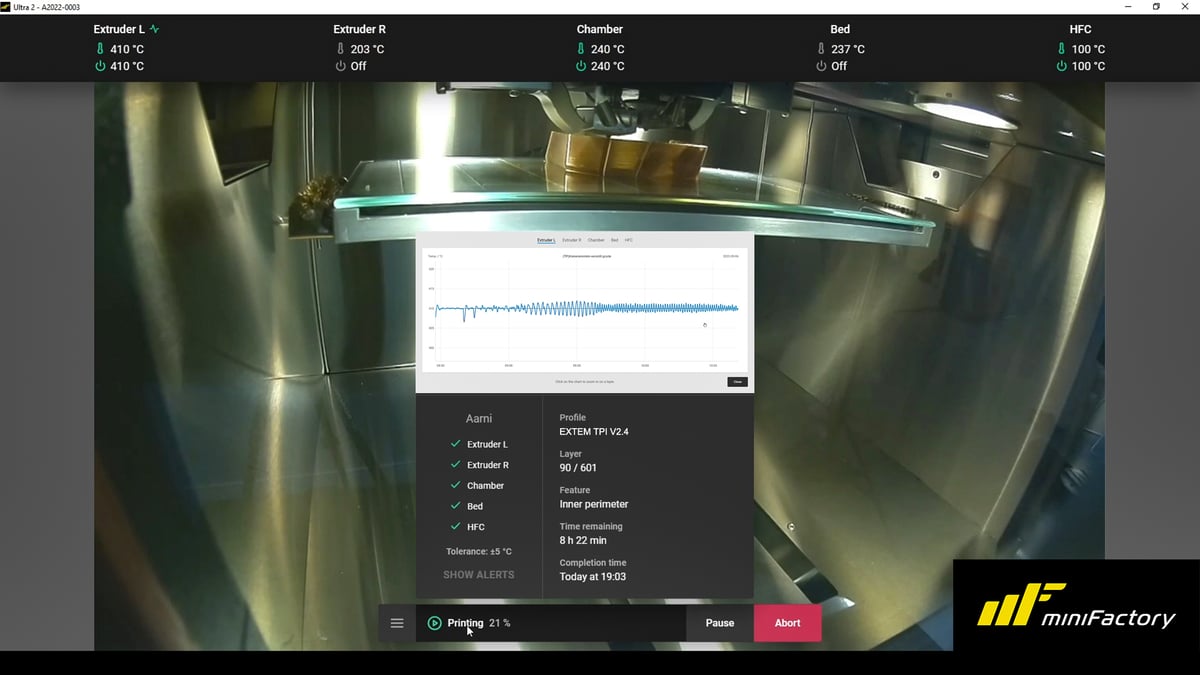

Called Aarni, this software is intended to give users a sense that the 3D printing processes going on in the build chamber are being monitored and recorded so that errors can be detected on the spot and successful prints are repeatable.

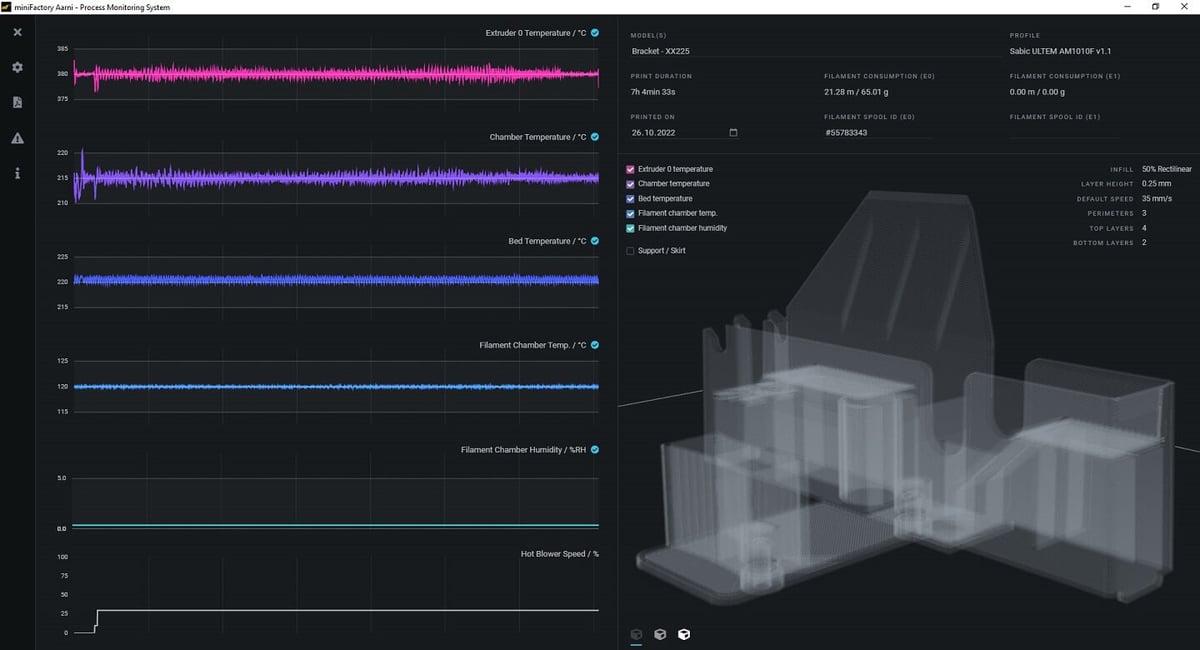

Although most industrial FDM 3D printers today have onboard cameras for live monitoring, Aarni goes a step further and records the material history of the part, any operator information, snaps of each layer, and a full process history, all detailed in a “manufacturing report.” The final report of each print includes the printing data of each layer compiled into a virtual part for inspection. Engineers can now see the statistics from the actual print job, layer by layer, and any deviations from the plan, especially any internal anomalies not visible from the outside that could affect part performance.

This is the tool engineers have been looking for, especially those working in sectors where parts must meet required quality control standards with documentation. Aarni is not a replacement for part inspection methods such as CT scans, but it is a long way toward giving operators some assurance that their parts have been produced as intended, along with the data to back it up.

“Our main goal is to make 3D printing a reliable manufacturing method to be used in the most demanding industries and applications,” miniFactory says.

With the ability to store validated printing parameters on a digital “master sample” document, manufacturers have a part recipe that can be followed on any miniFactory Ultra 2 at any location. This could open the door to more distributed manufacturing.

From any PC, users can monitor several printers a once with a live feed of the printer’s extruder, chamber, and bed temperatures; which layer is currently being printed; and when the process should complete. There’s also a pause and abort option controlled remotely. Previously, with the Ultra, data transfer worked via USB in the Basic model or an optional Security model using WiFi or LAN connection.

Now, Twice as Fast?

The just released Ultra 2 is an update to the company’s flagship Ultra but “two times faster”, the company says. How is it twice as fast, you may wonder. The company will only reveal that “improved technical solutions together with software optimizations” are behind the new 120 mm/s print speed for amorphous high-performance polymers.

On the outside, those familiar with the Ultra won’t notice much new with the Ultra 2. It has most of the same features, such as the same build size, servo motors, heated filament chamber, and integrated annealing setting. It’s still an open material system focusing on industrial thermoplastics, with print profiles for more than 50 high-performance materials, including PA, PEI, PPS, and PEEK.

miniFactory says the Ultra 2 has a new “smart” heated chamber that can be heated up to 250 ºC. Although the old heated chamber could take less than 30 minutes to heat and stabilize the printing chamber at 220 °C, the Ultra 2’s chamber features “triple censoring” and active temperature adjustment, enabling more precise temperature control, the company says.

Tech Specs & Pricing

- Technology: FDM

- Build volume: 330 x 180x 180 mm

- Extruder temperature: 480°C

- Chamber temperature: 250°C

- Platform temperature: 250°C

- Mechanics: AC-Servo Motors & Ball Screws Class C5

- Repeatability: 0,025 mm /400 mm

- Extruders: 2, separable extruders

- Materials: Open

- Price: ~ $60,000*

*miniFactory hasn’t released the price of the Ultra 2 yet, but the previous version, Ultra, retailed for about $50,000, so we estimate, with the upgrades, the Ultra 2 is in the $60,000 to $70,000 range.

License: The text of "miniFactory’s New 3D Printer is Factory Ready with Software to Ensure Print Quality" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.