Engineers from the Massachusetts Institute of Technology (MIT) have designed 3D printed mesh materials which they can tune to a patient’s body. The materials are flexible yet tough and were designed to support soft tissues such as muscles and tendons.

“This work is new in that it focuses on the mechanical properties and geometries required to support soft tissues,” says Sebastian Pattinson, who conducted the research as a postdoc at MIT.

3D printing is regularly used to create custom prosthetics and dental crowns. But, they are replacing hard parts of the body and, as a result, are made from hard materials.

The engineer’s work was instead designed to be used for wearable supports, such as knee braces, and implantable devices, such as hernia meshes. By 3D printing the material, customization is still possible.

3D Printing Flexible Mesh Ankle Braces

The researchers demonstrated their work by 3D printing an ankle brace using the flexible mesh. It supported the ankle by preventing it from turning inwards yet allowed the joint to easily move around.

They also developed a glove to help prevent involuntary hand movements which can occur after a patient suffers a stroke. This glove has a sewn in 3D printed mesh on top.

“3D printed clothing and devices tend to be very bulky. We were trying to think of how we can make 3D printed constructs more flexible and comfortable, like textiles and fabrics,” Pattinson said.

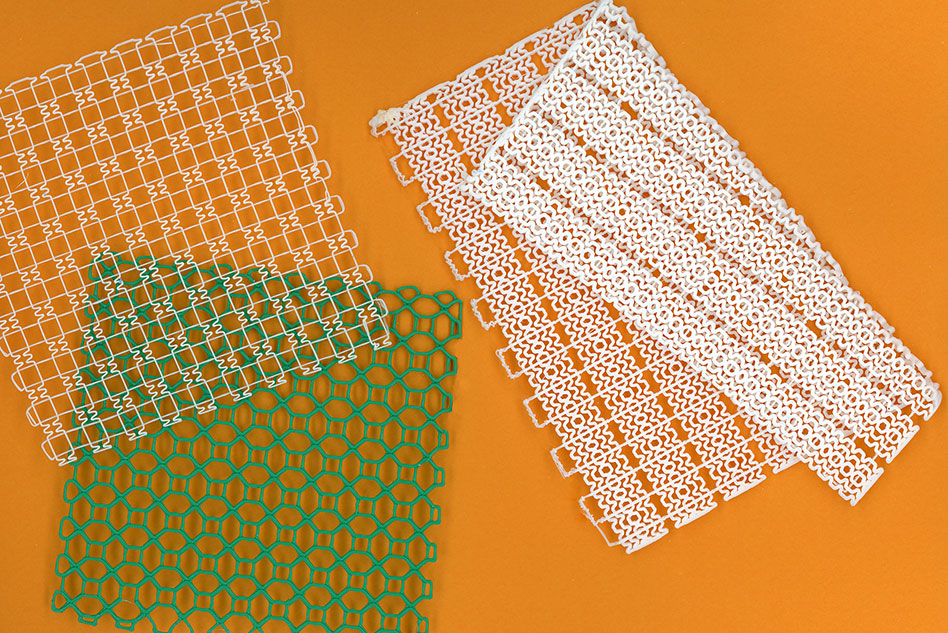

The team was inspired by collagen’s molecular structure – the structural protein which is found in muscles, tendons, and ligaments. Pattinson began designing patterns and used thermoplastic polyurethane (TPU) to 3D print his designs.

Thanks to the help of volunteers, the engineers tested their work and were pleased with the results. Associate professor of mechanical engineering A. John Hart said:

“The beauty of this technique lies in its simplicity and versatility. Mesh can be made on a basic desktop 3D printer, and the mechanics can be tailored to precisely match those of soft tissue.”

For an ankle brace, the material can be stretchy. However, for implantable meshes, the researchers needed to create stiffer materials which they managed by incorporating stainless steel fibers over the elastic mesh. They then print another layer of elastic over this.

“There’s potential to make all sorts of devices that interface with the human body. Surgical meshes, orthoses, even cardiovascular devices like stents — you can imagine all potentially benefiting from the kinds of structures we show,” adds Pattinson.

Source: MIT

License: The text of "MIT Engineers 3D Print Flexible Mesh to Support Healing of Soft Tissues" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.