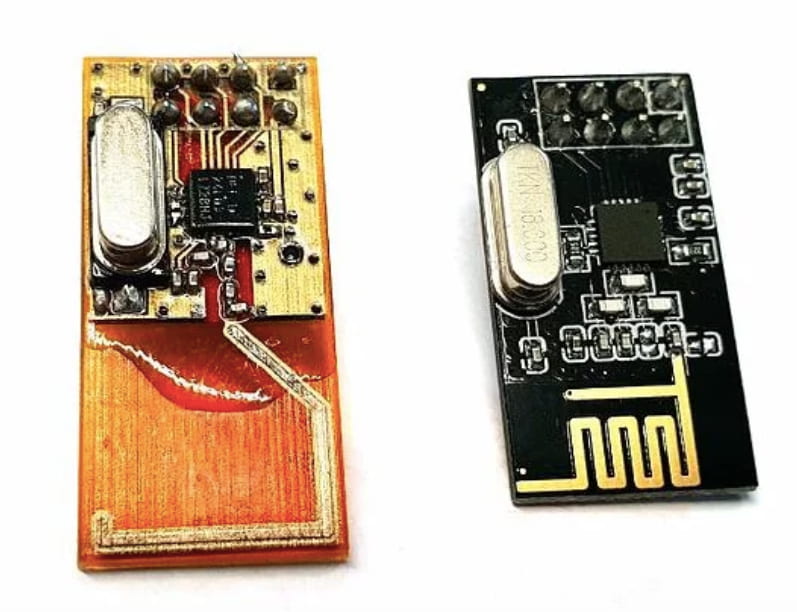

Nano Dimension, the Israel-based additive electronics provider, has used 3D printing to create a fully functional communication device (in other words, a 3D printed circuit board) in a much speedier time frame than it takes to create traditionally made devices.

The company explains that it took just 18 hours to 3D print, assemble and test the prototype IoT transceiver device using its DragonFly Pro 3D Printer. A traditionally made device would take around 14 days to create.

“An ever-greater emphasis is being placed on smart cities, smart buildings, smart homes and smart products by industries and consumers alike,” says Amit Dror, the CEO of Nano Dimension. “Our solution enables companies to speedily trial and finalize their prototypes in just one day without compromising on quality or performance.”

3D Printing an IoT Transceiver Device in 18 Hours

Thanks to reducing development times by 90%, the company hopes that research institutions and companies will begin 3D printing their own devices rather than waiting for third parties to supply them with traditionally made alternatives.

“They no longer have to wait over a fortnight to understand whether their smart device works or not. This ultimately increases product and cost efficiencies and reduces time to market, which means that the consumer can enjoy the benefits of these products faster than ever before,” adds Dror.

The DragonFly Pro 3D Printer was essential in creating the device as it miniaturizes electronics and is the only precision 3D printing system of its type. The resulting print is smaller than a “silver dollar coin” and is a remote-control style IoT device.

Nano Dimensions explains in a press release that uses for the device could be in two-way communication, such as a router. The device could help improve products for smart homes or be used by enterprises working on developing autonomous vehicles.

Source: Press release

License: The text of "Nano Dimension 3D Prints Fully Functional IoT Communication Device" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.