Almost all professional-level 3D printers can be run and monitored remotely. You can watch the print progress through imbedded cameras from anywhere, program switching from one filament bay to another, and queue up a series of prints via cloud-connected software. What you can’t do remotely is take the finished print off the bed.

Like changing a load of laundry, moving it from the washer to the dryer, removing a print from the bed is a tedious task. For engineers, it can add hours of work to their week and frequently interrupt their day because a print has to be removed as soon as it’s finished to keep production moving.

The folks at Mosaic Manufacturing, a Ontario, Canada-based 3D printer maker, have a solution. The Array ($80,000 – $95,000) is, as you’d guess, an array of four FDM 3D printers in an enclosed unit with an embedded robot gantry that removes and stores finished parts for you.

Mosaic introduced the Array way back in 2021. It’s been in field tests and pilot programs working out any kinks and is ready to order and ship starting today.

The target market for the Array are manufacturers that want to cost-effectively make polymer parts in-house and on demand. Mosaic developed Array as a solution to “overcome the scaling issues associated with traditional print farms,” it says, and offers the unit as a solution for 24/7 3D printing that can drop cost per part by up to 80% through time and labor cost savings.

Let’s take a closer look.

The Array is more than a printer cabinet. It houses four Mosaic Element or high-temperature Element HT FDM 3D printers, a robotic gantry system, and a cart to store the completed prints and empty print beds.

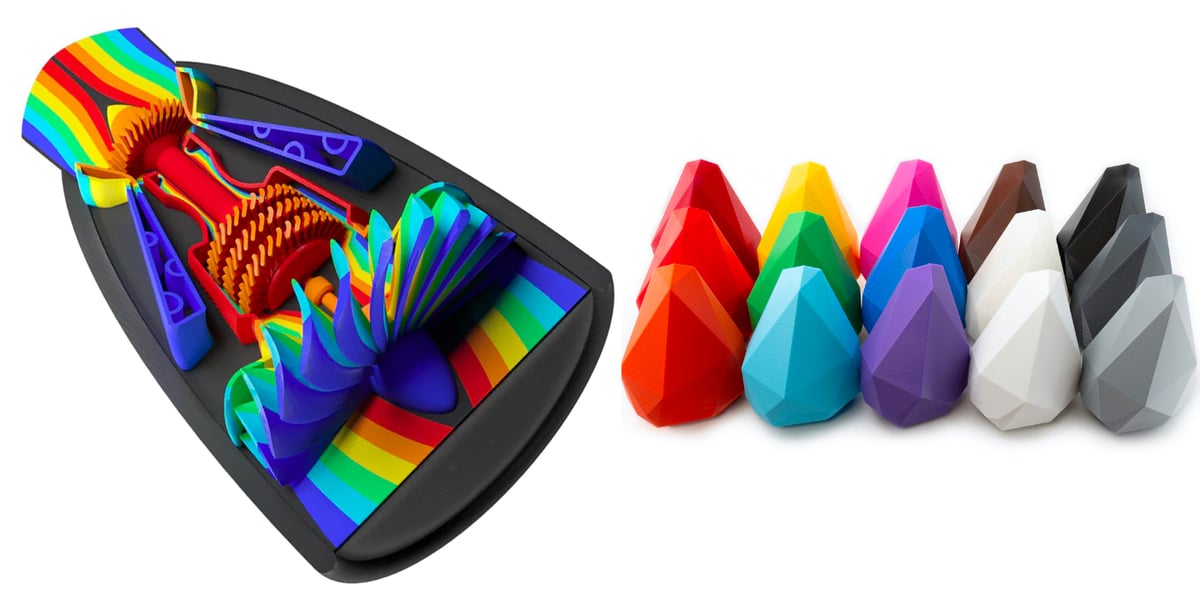

Each Element 3D printer inside Array can have eight materials bays each, automatically switching between them to enable a single part with up to eight materials. The material changer is called Palette X. It automatically feeds a new material to the single extruder “avoiding complex multi-nozzle calibration and messy nozzle dripping,” the company says.

In fact, this patented material changer is what Mosaic has had on the market for years. The Mosaic Palette entered the scene back in 2014 and made a splash with a successfully funded Kickstarter campaign. The Palette’s goal was to bring multi-color 3D printing to any machine and the original device did that in an innovative way. The new X version can now exchange more materials than be before.

With eight materials per printer, you could pack your Array with 32 different materials, ranging from PLA to PEEK.

32 Flavors of Filament

Mosaic offers its own materials but the Element printers are open to third-party brands, but only materials that fit into Mosaic’s Material Pod will be able to access material automation and multi-material 3D printing.

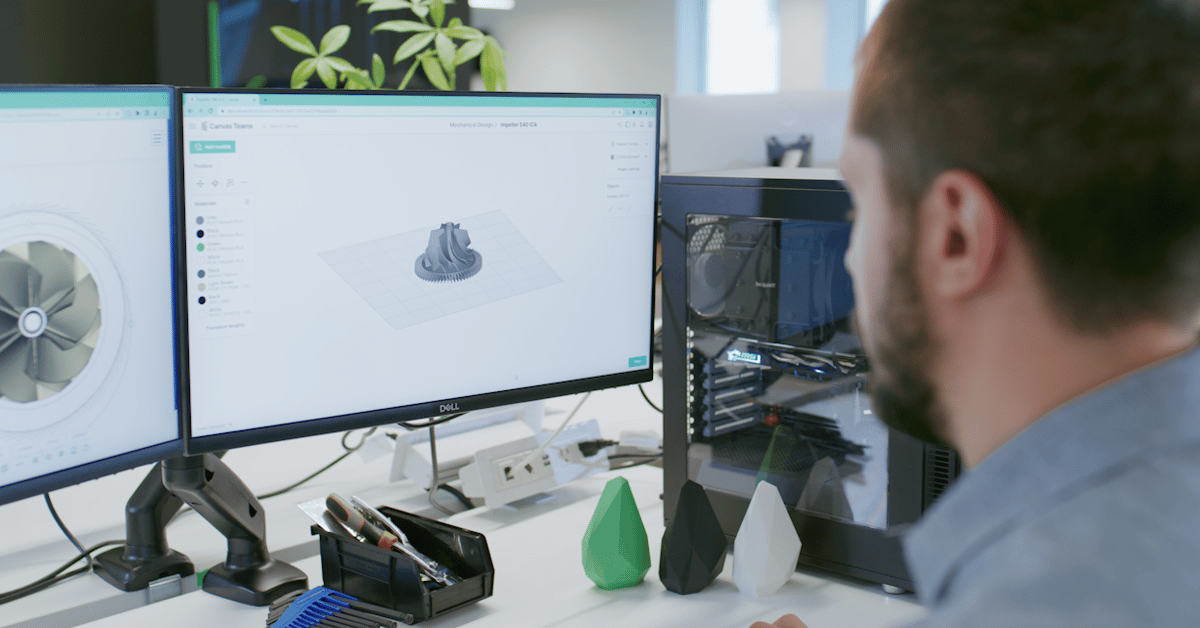

The software running Array is called Canvas. It controls all of your printing workflows with “smart queueing,” detailed dashboards, and project management. Users can collaborate with Canvas teams to share files and run prints for team members. Canvas Edu, the education version, enables schools and institutions to manage thousands of student submissions from a simple dashboard.

The Four Internal Element Printers

Each printer in the Array has a print volume of 355 x 355 x 355 mm and its own in-chamber camera. The minimum layer height is 20 microns, print speed is 100 mm/s, and a bed temp to 120ºC.

You can fill your Array with either Element or Element HT printers. The versions are nearly identical, but the HT (high temperature) features a heated chamber to 80ºC.

The versions of the Element inside the Array are not identical to the desktop versions. They are functionally the same but lack the touch screen, user interface, and status light since these systems are on the Array unit as a whole. The front door of the printers inside of Array are also different because they are designed to be opened by a robot.

Should an Element unit need repairs, you can quickly swap them out for another unit.

Tech Specs

Array Features

- 4x Element or Element HT 3D printers

- Automated robot that picks up finish prints and prepares the printer for the next print.

- Automated bed changing

- 32 automated material pods

- Fume extraction hookup

- Mobile storage cart for finish builds

- Auto remote monitoring systems

- Palette X material changer

- Price: $80,000 with 4 Element 3D printers, $95,000 with 4 Element HT3D printers

Element HT 3D Printers

- Technology: FDM

- Print volume: 355 x 355 x 355 mm

- Min. layer height: 20 microns

- Print speed: 100mm/s

- Max. bed temp.: 120°C

- Heated chamber: 80°C

- Air filtration: HEPA or a BOFA filter

- Max. nozzle temp.: 500°C1

Field tested by Avid Product Development, a Lubrizol Company, and PolyUnity Tech, the Array is now available in North America.

License: The text of "New Automated Print-Farm-in-a-Box From Mosaic" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.