Markforged, a US-based manufacturer of polymer, carbon fiber, and metal 3D printers, has been one of the industry’s top brands for years, so it’s time we saw a few major updates from the company.

This week, All3DP spoke to Markforged about their three enhancements that effect nearly all Markforged printers and offer some new features. The focus is on enabling manufacturers to recover faster when parts break, operate with less on-hand inventory, and minimize equipment downtime.

Next Day Metal

Let’s start with the software update that speeds up your current Markforged printer, which is available now. Yes, new printer settings in the latest update to Next Day Metal, will actually increase the print speed of your current Markforged metal printers.

This over-the-air software update “unlocks” print speeds up to twice as fast as before to produce high-quality, strong metal parts, the company says. New software setting for wash and dry times are more accurate for smaller parts, shortening the required debind cycle time.

There’s also a 17-hour small parts “express run” on the Sinter-2 post-processing oven that can give you parts faster and — because of increased capacity on each printer — lets you scale-up your production capacity.

“Behind Next Day Metal’s increased print speeds are improvements to actual travel and extrusion speed, with no change to layer resolution,” Paulina Bucko, Markforged’s head of communications. “We began experimenting with print speeds, challenging our old assumptions about the correlation between speed and quality, and found that we could boost speeds without compromising surface finish. Metal X customers will simply see faster printing with this update, with no caveats. As we continue to innovate, we hope to bring similar improvements to other metals in Markforged’s materials lineup.”

To illustrate the new faster print ability, Markforged points to a case study where a manufacturer that was able to produce metal prototypes in three days, can now produce the same overnight.

Metal X Gen 2

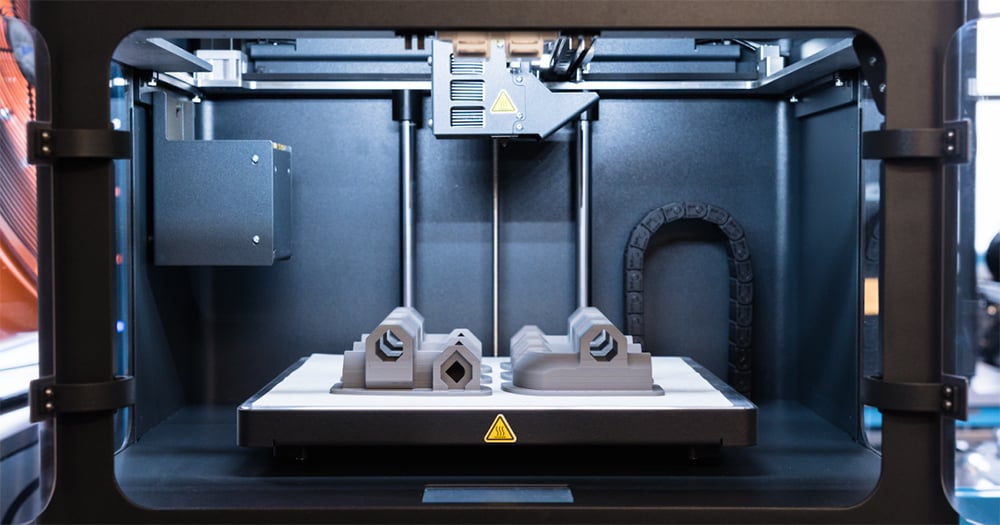

Now let’s take a look at the new generation of the Markforged Metal X.

The Metal X Gen 2 is more of a tweak than an overhaul, but offers some attractive new features nonetheless. The original Metal X System, released in 2017, made quite a splash pushing the boundaries of what was possible in printing complex, industrial-grade metal parts in an office environment.

The Gen 2 features some hardware developments that improve the user experience, such as an external 7-inch touchscreen; improvements to operator safety, such as the new door position sensors; and updates that make the Gen 2 more energy- and time-efficient, such as additional chamber insulation.

This may not sound like a totally new generation of Metal X, but Markforged told All3DP that the Metal X system you see today, as a whole, is totally different from the original Metal X. “Since 2018, we have launched five new specialty materials, developed a bigger, faster furnace, and continuously deployed software improvements across the fleet to improve quality, speed, and accuracy,” says Bucko. “Gen 2 and Next Day Metal are the culmination of process improvements over the last three years, and the exhaustive testing required to get here.”

That said, Gen 1 does not get left behind. The Next Day Metal software update enables you to go “from art to part” in as little as 28 hours, Bucko says.

The full Metal X system – Metal X Gen 2 printer, Wash-1, Sinter-2 – starts at $179,990.

Markforged X7 Field Edition

And now on to the cool accessories: the military-grade travel case.

If it wasn’t for the price tag you might want this for luggage, but the case that makes the X7 a “Field Edition” is a timely response to the increasing use of additive manufacturing on site at remote locations in either the oil and gas industry, or for deployed military. In fact, the U.S. Marine Corps XFAB program has field tested the Markforged X7 in the field.

The main difference between an X7 and a X7 Field Edition is the outer case, custom foam inserts, and included tools, consumables, and spare parts, such as print head and extruder. The printer also substitutes the lower material storage cabinet found on the standard X7, opting for a simplified drybox setup like the Mark Two.

The X7 FE starts at $89,500

Markforged says you can “drop” – presumably by aircraft – the unit directly into harsh environments like combat zones and exploration sites and be printing in less than two minutes. The high-impact polyethylene Pelican case will protect the printer inside.

The Metal X Gen 2 and Next Day Metal for both the Metal X Gen 1 and Gen 2 are currently available. The X7 FE is available for pre-order and scheduled to ship in the autumn of 2021.

License: The text of "New Markforged X7 Field Edition & Metal X Gen 2" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.