Looking to bridge the gap between affordability and quality in professional resin 3D printing, California-based Nexa3D just launched the NXE 200, its fourth resin printer.

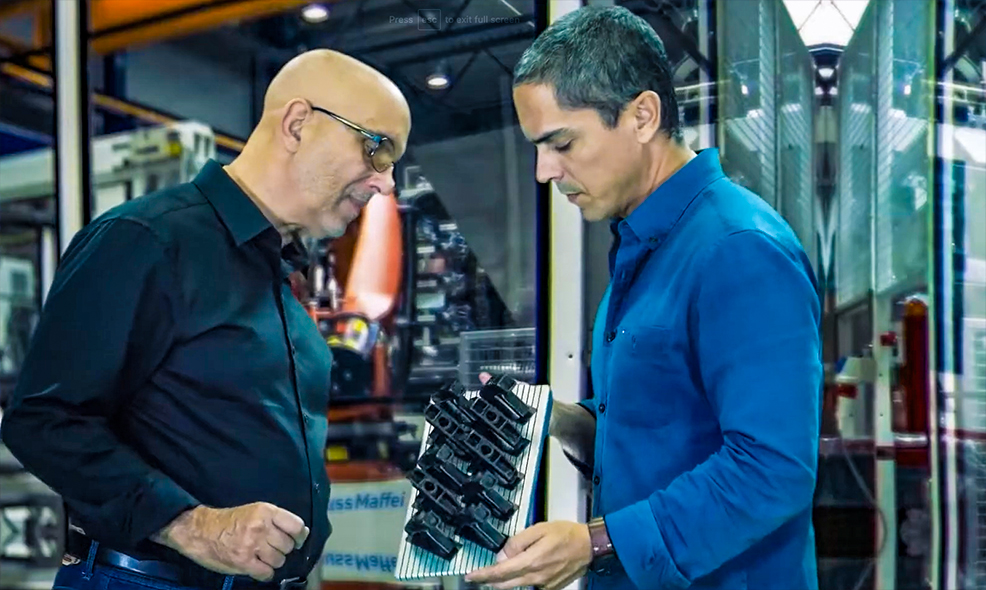

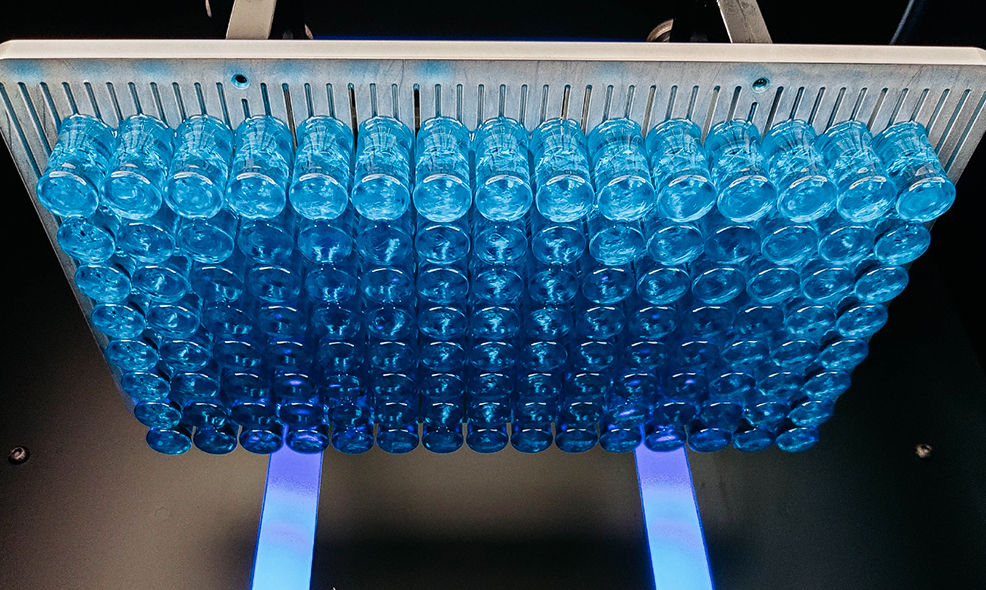

At $50k, the NXE 200 targets that elusive middle ground between prototyping and production capability. The goal is to give designers, engineers, and manufacturers who need fast and accurate prototypes, the ability to scale up to batch manufacturing on the same platform. If your shop uses one technology for iterations and then switches to another printer with its own workflow and set of perimeters for batch production, you know what a hassle that process is.

The NXE 200 is an industrial masked stereolithography (MSLA) 3D printer with all the features you’d expect, but at a price point to lure a new audience to volume additive manufacturing. Let’s take a closer look.

Tech Specs

- Build Volume: 10.8 x 6.1 x 7.8 inch (275x x 155 x 200 mm)

- Max Resolution: 4K (3840 x 2160)

- Pixel Pitch: 76.5 µm (0.0030 in)

- Wavelength: 405 nm

- Price: $49,999

- Build Materials: open material platform for UV curable plastics. xGPP-Translucent; XGPP-Grey; xPRO410; 3843-ABS-Black; xCE-Black; ABS-Black; xCE-White; xPP405-Black; xPP405-Clear; xPEEK147; x45-Natural; x45-Clear, x45-Black, xFlex

Nexa3D’s Other 200

NXE 200 has nearly identical features to the company’s existing NXD 200. The “D” in NXD may stand for dental since this is the printer Nexa3D created for that market. But, not wanting the dental labs to have all the fun, the NXE – no guess what the “E” might stand for – features the same price, build volume (275 x 155 x 200 mm), 4K resolution, and signature tech.

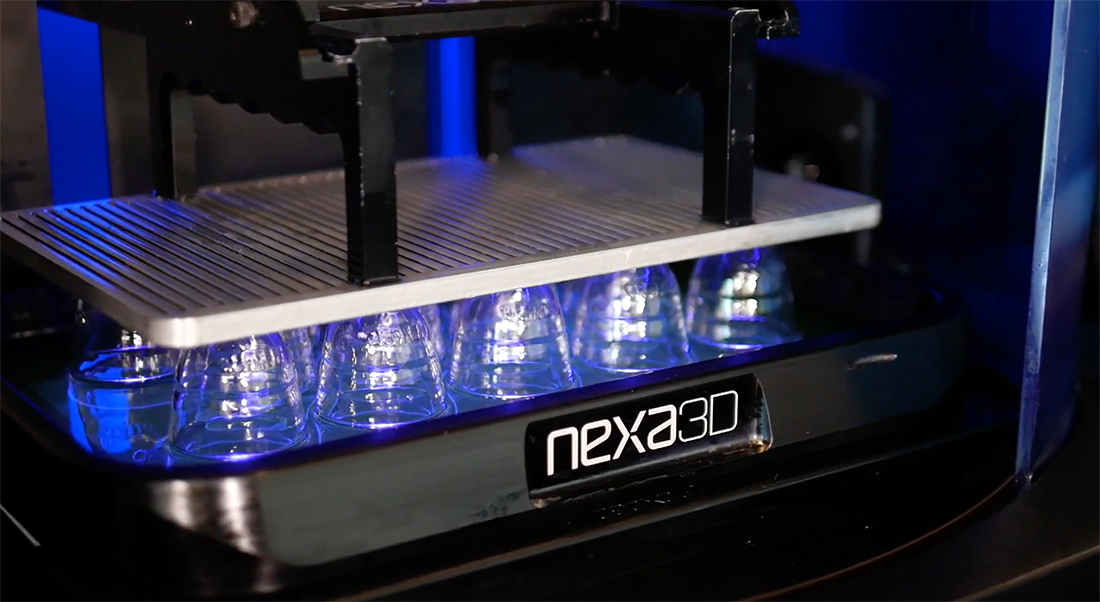

If you’re not already familiar with Nexa3D resin technology, a patented feature called Lubricant Sublayer Photo-curing (LSPc) is at the heart of its speed and accuracy. The company says the self-lubricated membrane in its technology enables fast printing because it helps to move resin to every area of the print platform, which eliminates the delamination forces between the part being printed and the build area – this force is what makes other resin printers produce parts more slowly. The membrane itself, called Everlast 2, has a long lifespan, Nexa3D says, which results in more printer uptime and lower consumables costs.

The NXE 200 also features the same 4K LCD light engine you’ll find in Nexa3D’s NXE 400 and NXD 200. Speaking of the larger NXE 400, it’s currently priced at just $10k more than the new NXE 200, but features twice the build volume and twice the height. That $10k difference is apparently the make or break point in adopting production SLA.

When addressing affordability, however, Nexa3D’s open-source material capability is where you’ll save a lot of money over some other industrial resin printers. Not being locked into using only manufacturer proprietary resins also opens more doors for wider applications.

Nexa3D partners with materials manufacturers, including Henkel and BASF, to offer a resin portfolio backed by tested print perimeters within its NexaX 2.0 software.

The full resin 3D printing workflow includes washing and then curing parts, of course. Nexa3D’s existing xWash and xCure round out the full NXE 200 hardware platform.

Special Introductory Offer

Until the end of May, the NXE 200 at $49,990 with installation included comes bundled with the xCure curing unit and NexaX 2.0 software.

License: The text of "Nexa3D’s New MSLA Targets Affordable Industrial Resin 3D Printing" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.