Scantech has announced the launch of NimbleTrack, a groundbreaking wireless 3D scanning system designed to change the way users measure and analyze small-to-medium-sized parts. It is highly wireless and agile to cater to different industrial settings, making it a powerful tool for engineers, designers, and manufacturers.

Incredible Compact & Plug-and-Play

Lightweight and compact, NimbleTrack aims to set a new standard for the optical 3D scanning system.

Its lightweight design allows users to measure parts wherever you need it. With a length of 57 cm and a total weight of 2.2 kg, i-Tracker stands out by delivering easy uses. Besides, engineers and professionals can use the 3D scanner, weighing only 1.3 kg, for long periods without feeling tired.

The system comes with a small standard protection case that can accommodate all its instruments to deliver flexible and convenient uses.

Stable Structure With CFFIM Technology

NimbleTrack’s 3D scanner embraces an innovative Carbon Fiber Frame Integrated Molding (CFFIM) technology to ensure lightweight design and high strength, breaking through the limits posed by traditional assembled structures. With a steady structure, device is highly stable and wholly unaffected by thermal variations. A single calibration process can ensure it works steadily for a long period of time. Users can enjoy full control over every scan with this cutting-edge technology.

Wireless Freedom

This nimble optical 3D scanning system intends to set a new benchmark for wireless and free 3D scanning. It has eliminated the need for any cables to power the instrument, use its functionalities, or transfer data. This enables on-site measurement in a variety of environments, even in situations where there is no outlet or power supply available.

The 3D scanner has a built-in powerful battery, and the tracker comes with standard plug-in batteries to deliver a dual power cycle, ensuring continuous operations over a extended periods of time. All of these advancements allow users to enjoy free measurement experiences.

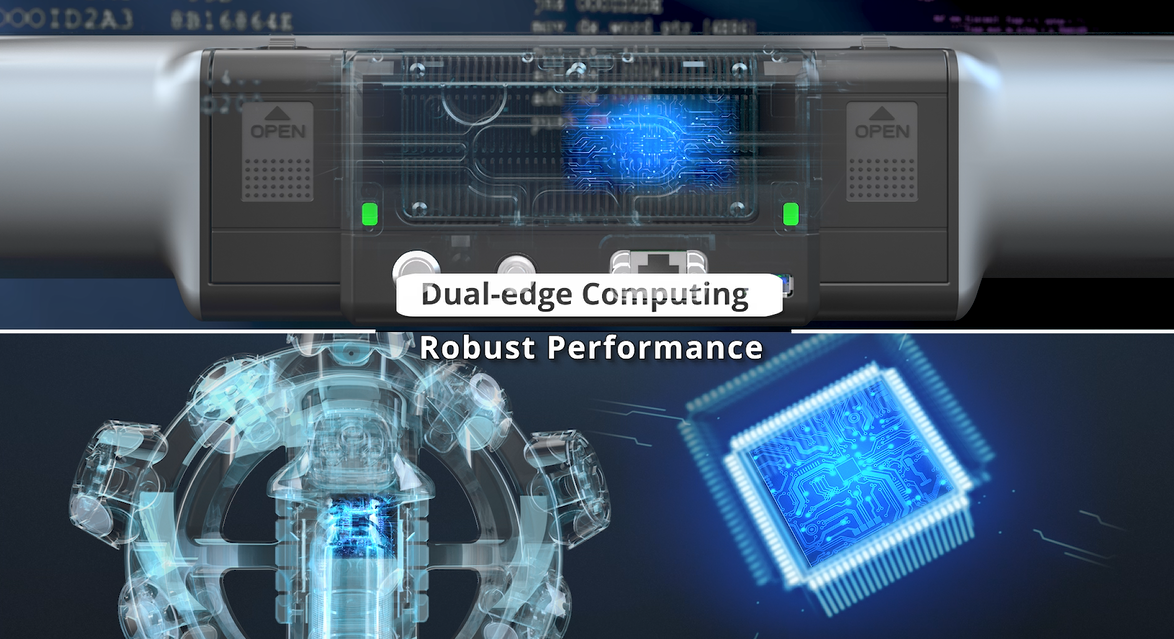

Dual Edge Computing and Robust Performance

Both NimbleTrack’s 3D scanner and tracker have powerful edge computing modules, which enables it to deliver fast and smooth scanning experiences at a high frame rate of 120 FPS.

When compared with common handheld 3D scanners, it saves the need for a power supply and the hassle of sticking targets, which highly streamlined measurement processes. It tackles complex tasks with ease by delivering target-free and efficient 3D scanning.

Unleash Precision, Unleash Excellence

Users can utilize the full potential of Scantech’s metrology products and advanced algorithm, the system achieves an accuracy of up to 0.025 mm and maximum volumetric accuracy of 0.064 mm across the whole range. Leveraging high-precision and usability, NimbleTrack enables users to capture 3D data with meticulous details.

Next Level 3D Scanning

NimbleTrack is designed to be both compact and flexible, allowing users to explore novel applications for industrial measurements.

When dealing with narrow spaces or hard-to-reach areas, the 3D scanner can be operated wirelessly and independently, allowing for instant scanning and one-handed control. This enables high-precision scanning of up to 0.020 mm at any time and in any location.

When measuring even larger-sized parts, the optical tracker can further enhance precision by using its built-in infrared large-area photogrammetry to reduce accumulated errors accumulated by scan alignment.

Get the Most From Your NimbleTrack

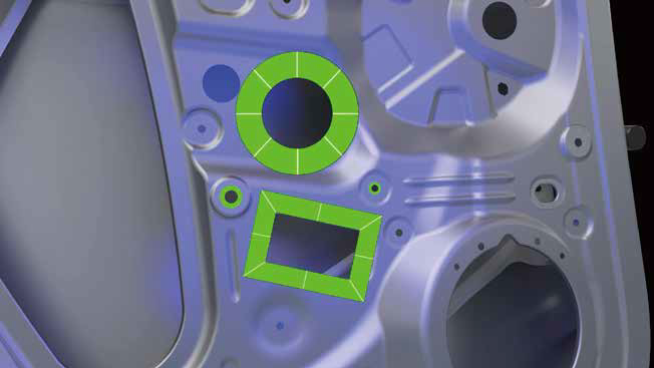

Intelligent Edge Detection

NimbleTrack boasts a stand-out function of precise edge detection, which is enabled by gray-value measurement. Users can inspect closed features such as holes, slots, edges precisely and obtain information such as positions and diameters.

i-Probe500

It can be paired with a tracking i-Probe to probe inaccessible areas such as reference holes and hidden points. This contact measurement probe can ensure precise results with both wired and wireless options.

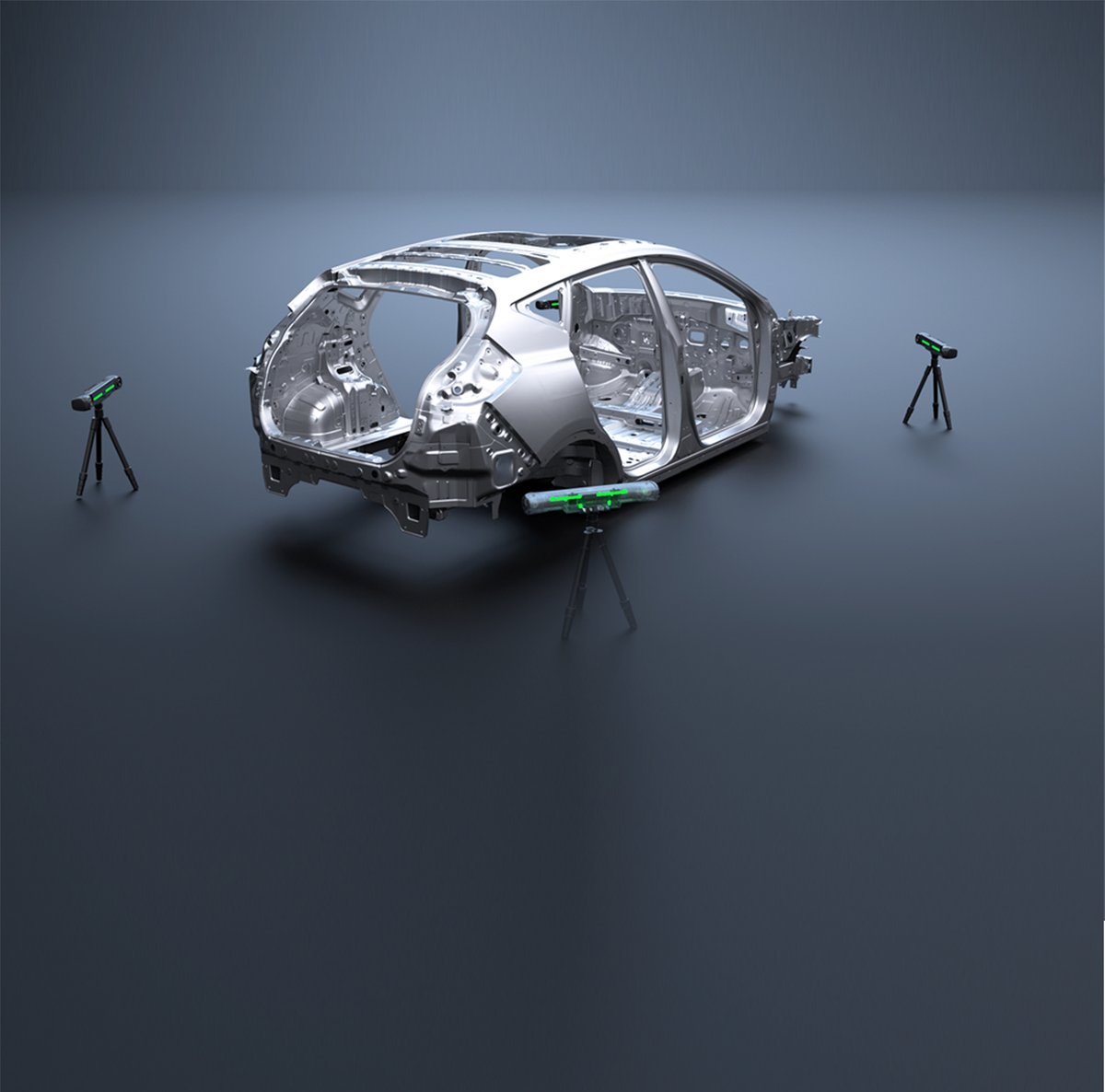

Multi-tracker Measurement

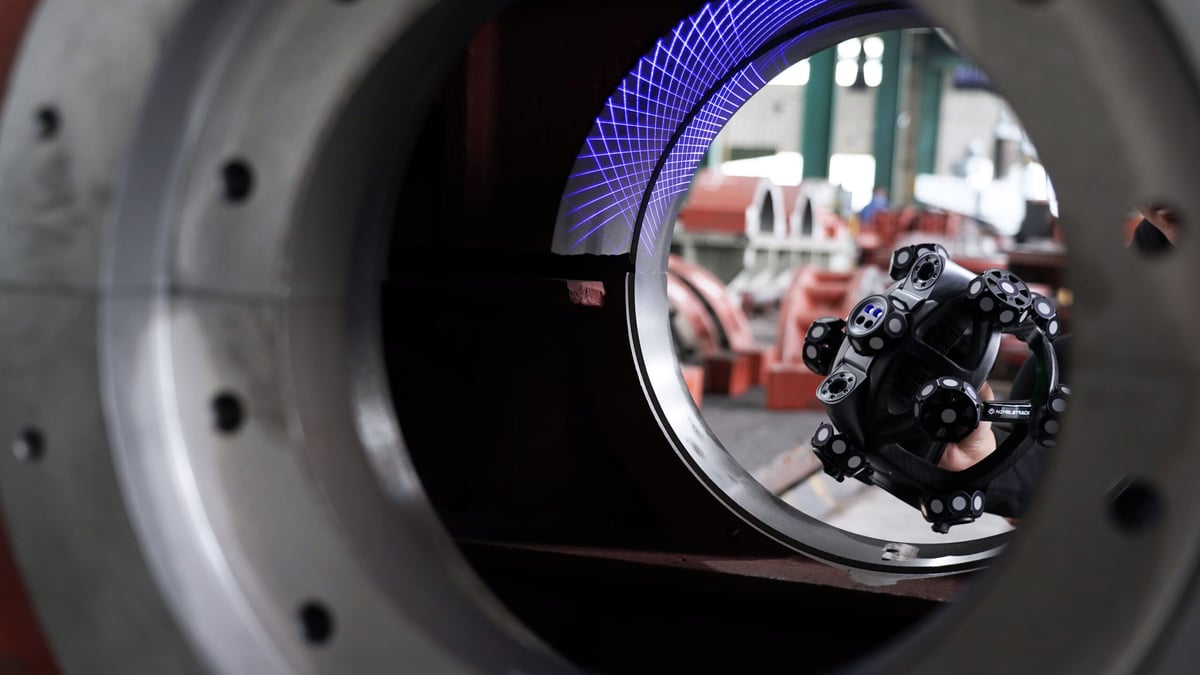

Its measurement range can be dynamically extended by adding more i-Trackers so that it can measure large-scale objects without compromising accuracy.

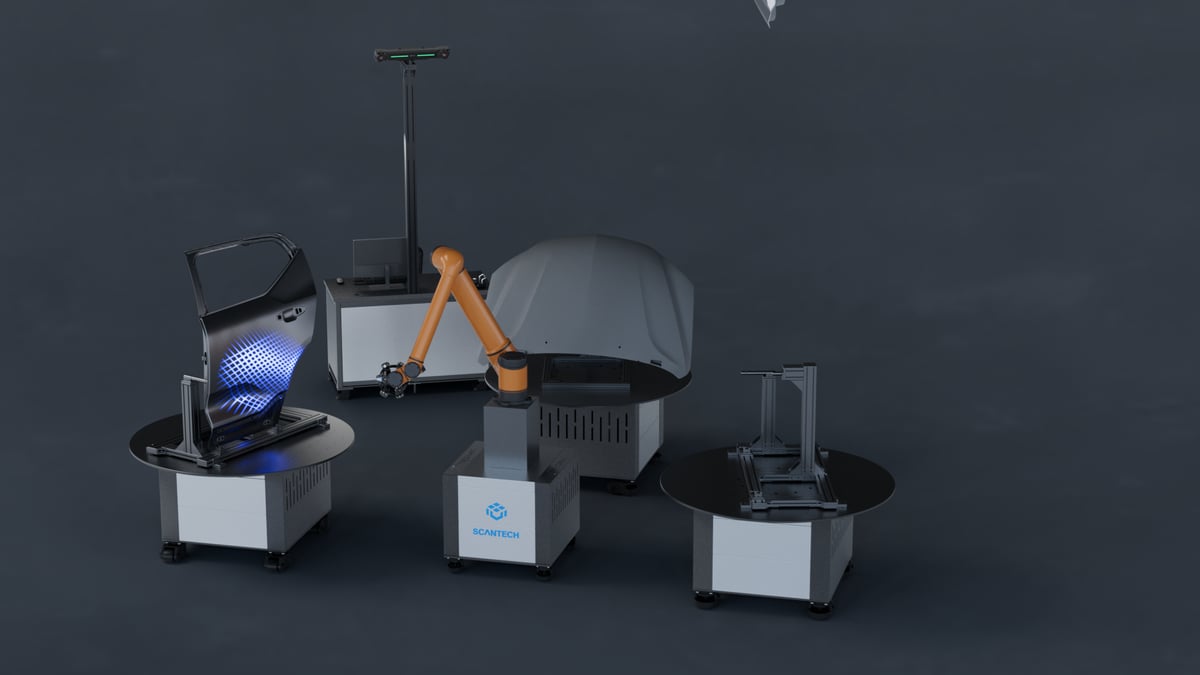

Automated Measurement

On the basis of the new 3D scanner architecture, Scantech offers a customized clamping method for automated measurement, making it more compatible with various types of robots. Its 360-degree evenly distributed target sets allow for all-round and precise tracking, facilitating forming efficient automated batch measurement systems.

Applications

With the NimbleTrack, Scantech is confident that its versatile and powerful device a leap forward for industrial 3D scanning applications. From the automotive to aerospace and beyond, the wireless capabilities and versatile functionality will enable users to work smarter and faster.

As for scanning area, NimbleTrack is optimal for measuring parts ranging from 40mm to 2000mm. Typical components include car doors, hoods, interior seats, die-cast parts, and new energy battery boxes.

NimbleTrack is also ideal for applications when markers are not allowed to be applied, including aircraft maintenance, artifact protection and automated measurement.

The NimbleTrack system truly excels in situations where connecting to a power source is inconvenient or where lengthy cables could jeopardize safety. Think of scenarios like field measurements of corroded oil pipelines or high-altitude scanning of large parts. In these contexts, NimbleTrack stands out as a reliable solution.

NimbleTrack streamlines production processes, ensuring precise measurements during assembly, quality checks, and final inspections. Engineers and designers can rely on NimbleTrack for accurate 3D scans, aiding in product development and rapid prototyping.

To learn more about the NimbleTrack, visit Scantech’s website here.

About Scantech

SCANTECH (HANGZHOU) CO., LTD. is a global provider of comprehensive 3D solutions. We specialize in R&D, production, and sales of 3D scanners and 3D systems and boast a long history of developing hardware and software. We offer two main product categories: industrial high-precision 3D scanners and professional, cost-effective 3D scanners, including portable 3D scanners, tracking 3D scanners, industrial automated 3D systems, and professional color 3D scanners.