Many manufacturers and small businesses certainly have struggled with this question: Do we need a metal 3D printer or a polymer 3D printer? There are countless scenarios where carbon-fiber-infused nylon can stand in for metal, but as tough and durable as it is, some applications just call for stainless steel.

One 3D printer manufacturer that makes both types of 3D printers has seen customers wrestle with this dilemma. Markforged makes four — and undoubtedly the most popular — continuous-carbon-fiber composite 3D printers on the market: the FX20, FX10, X7, and Mark Two. It also makes an easy-to-use metal filament 3D printer called the Metal X System. Combining the two technologies seemed obvious, but took some years of R&D to actually optimize, says company CEO Shai Terem.

Rather than a new machine, the capability to 3D print with a new metal filament has been added to the FX10 continuous carbon fiber 3D printer introduced last November. Markforged says the FX10 was designed to be modular and accommodate coming years’ innovations whatever they may be. At launch, the FX10 was touted as “the additive manufacturing platform for the next decade.”

As the latest in the company’s fleet, the FX10 was already much faster and more advanced than the older models due to a new proprietary print file format, a stronger gantry with more powerful motors and CoreXY motion system, plus a direct drive extruder and a new extrusion system design.

Now, existing FX10 owners and new buyers can purchase the optional Metal Kit to enable metal extrusion 3D printing.

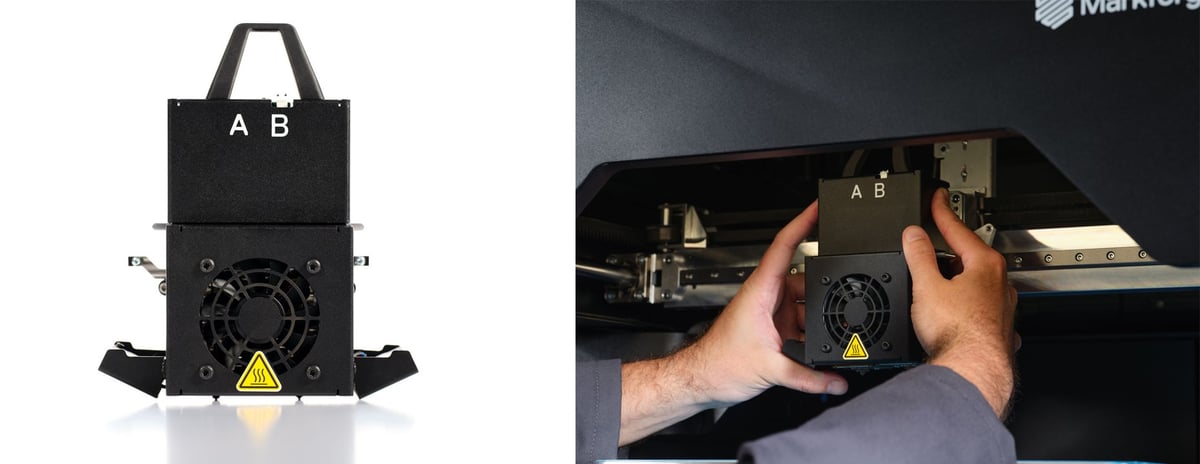

The FX10 Metal Kit ($19,000) consists of a swappable print “engine” that includes a metal-specific print head, material feed tubes, routing back, and dual pre-extruders. The swap takes about 15 minutes.

The Metal Kit, however, is not the same system as you’ll find in the company’s Metal X 3D printer first launched in 2019. Just as the FX10 is a step beyond the company’s previous composite 3D printers, the Metal Kit enables faster metal printing than the Metal X. Plus, the FX10’s print volume is larger than the Metal X’s (375 x 300 x 300 mm vs. 300 x 220 x 180 mm). Is the Metal X solution going away? Terem told All3DP that the Metal X solution has capabilities, like more metal material, that, are not yet available on the FX10, but eventually, he does see the system replaced by the FX10.

Metal prints are built from a new type of metal filament and a ceramic release filament that prints a barrier between part and support for easy removal. Markforged developed a new 316L stainless steel metal filament to be used with the FX10 Metal Kit. There’s also a 17-4PH stainless steel and more metal filaments in the pipeline. Terem told All3DP that the new metal filaments are more flexible and print faster than the company’s older materials.

As with the Metal X — and all metal filament 3D printing for that matter — once prints are complete, they must be washed and sintered in two post-processing steps to become solid metal parts. Markforged already offers Wash-1 and Sinter-2 machine options for these tasks.

Eiger, Markforged slicer and print management software, automates the printing and post-processes, including scaling parts to account for shrinkage during sintering.

Technical Specs & Price

License: The text of "One 3D Printer for Metal & Continuous Carbon Fiber New From Markforged" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.