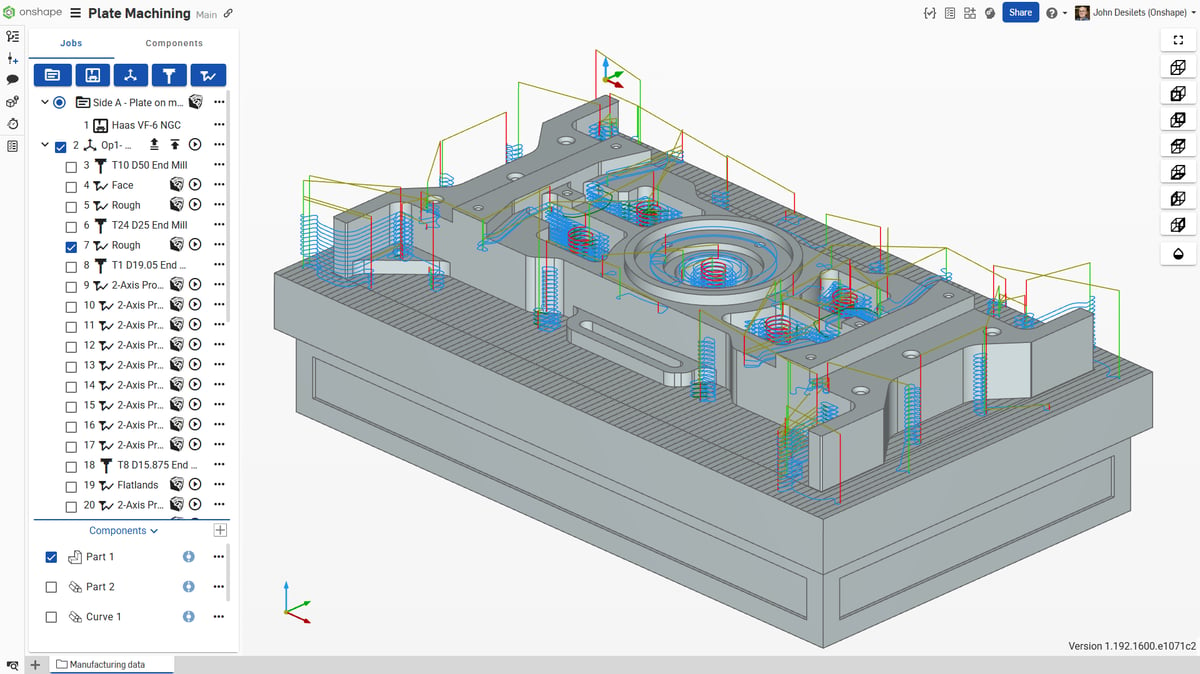

Another computer aided design (CAD) software maker coming out with a computer aided manufacturing (CAM) solution may not sound that fascinating until you realize it’s completely cloud-based, which offers more advantages than you may realize over desktop-based solutions.

All3DP sat down with the folks at PTC, which makes Onshape, for an eye-opening tour of the features of the new Onshape CAM Studio and got insights into what’s to come over the course of the next 15 updates planned for 2025.

Why Cloud-Native Matters

First, cloud-native software enables an easier and faster digital workflow between designers, engineers, machinists, and customers that’s more efficient than file-based workflows and relying on locally installed software. The database-driven architecture, similar to Google Docs, has several advantages over traditional installed CAD/CAM systems ranging from permission-based file viewing to near infinite compute power to no updating software, ever. You also don’t need to have a high-powered computers or worry about compatibility with Mac or Windows.

These benefits of Onshape were always there, but it’s with the new addition of CAM — and the need to share and collaborate more between stakeholders — that they are put into sharper focus.

“This is something that a lot of people miss,” says Darren Henry, senior VP of general operations at PTC. “You not only have software that you can access anywhere, but you have the compute power and the data stored in the cloud, and that fundamentally changes your workflow.”

For example, if you’re a company designing consumer electronics and you want to work with multiple vendors overseas, you can instantly share file access to Onshape then retract that permission if necessary, not send copies of files around the world.

Onshape, known for being a robust yet easy-to-use CAD program, was acquired by American software company PTC in 2019. Not that long after, loyal users began asking for CAM functionalities.

“By 2023, we had addressed most of the fundamental gaps in what users expect from a CAD system,” says Henry. “Expanding into CAM now feels like a natural progression, extending the benefits of cloud-native technology even further.”

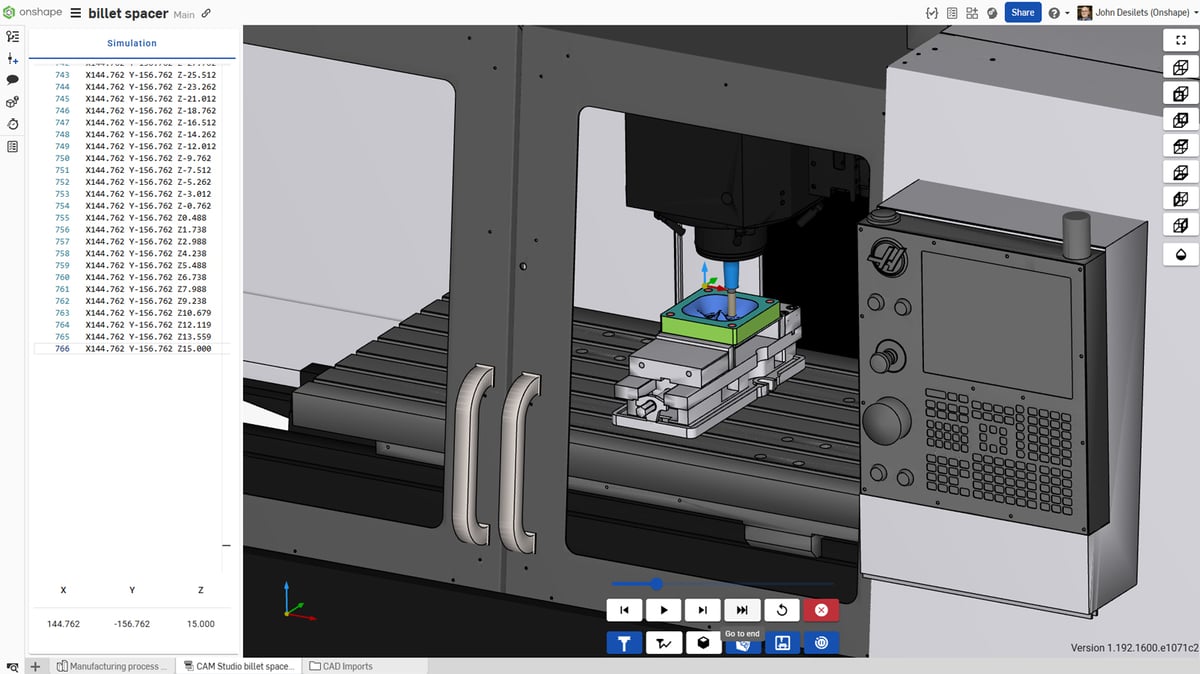

One example of the benefits of using CAM in the cloud is having the computation power AWS (Amazon Web Services) behind it.

“Let’s say you have a very complex CAM operation that requires multiple toolpaths,” says Henry, “you can simultaneously calculate hundreds of toolpaths very quickly, where as a laptop can do maybe eight simultaneously.”

Features Now, Features to Come

Currently in beta, Onshape professional and enterprise paid plan subscribers have access for no additional cost to CAM Studio, which currently only features 2.5- and 3-axis milling on a limited range of machines. A long menu of more functions, features, machines, and AI will be rolled out in 2025, which led us to ask, why launch now with so much more on the drawing board?

“The majority of machined parts can be produced using 2.5- and 3-axis machining strategies,” says Jake Delano, Onshape’s senior technical services engineer. “In future releases for CAM Studio, we will introduce 4- and 5-axis milling to support more advanced geometries, such as turbine blades.”

In addition to the CAM features, other workflow capabilities, like establishing unified tool libraries at a company level, should also debut in 2025, Delano told All3DP.

Comparisons of Onshape to Autodesk’s fusion are common and will become more so with the addition of CAM. Fusion also offers CAM and a host of other features more directly related to 3D printing, such as nesting for powder bed fusion and slicing for FDM 3D printers like Bambu Lab. Henry says PTC is not seeing demand from users for these types of features since they’re offered by the 3D printer makers themselves in most cases and are a redundancy inside of CAD/CAM software.

“What users are responding well to is having Onshape on their mobile devices accessible from anywhere,” says Henry. “Their mobile usage is through the roof.”

How to Get CAM Studio

Accessibility to the CAM Studio is limited to Professional and Enterprise (not Standard) paid plans now but is coming soon to the Educational licensing, Henry says. Students and educators can get professional-grade CAD free of charge through the educational license.

CAM is also included for free for those in Onshape’s Startup Program. Eligible startups can apply to receive five Onshape Professional licenses at no cost for at least a year that include CAD and CAM capabilities.

Don’t expect to see CAM Studio in the free plan, which hobbyists tend to use. However, you can try CAM Studio for free for up to six months through the new Discovery Program, which is an opportunity for qualified users to try out Onshape Professional.

Security in the Cloud

Security has been a hot topic in additive manufacturing recently and there can be misconceptions about cloud-native software.

“We believe we’re far more secure than any desktop solution,” says Henry pointing to Onshape’s login credentials, two-factor authentication, and in-flight and storage data encryption.

PTC plans to launch an Onshape government edition meeting ITAR requirements. It already offers Onshape Government Enterprise, which is its cloud-native CAD & PDM solution tailored for U.S. government agencies on AWS GovCloud that meets ITAR and EAR compliance requirements.

If you’re an Onshape user, the program just got better and if you’re shopping for a CAD/CAM solution PTC is disrupting the space where there’s no clear leader with an offing that ticks a lot of boxes for modern design and machine shops.

You May Also Like:

License: The text of "Onshape’s New Cloud-Native CAM is Cooler Than You May Think" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.