EVA (pronounced ‘EV-UH’) is a modular carriage system adaptable to many kinds of popular extrusion system hardware.

The project was developed by Paweł Kucmus (pkucmus on GitHub) along with the EVA and Rat Rig community. As described on the project website: “EVA is a 3D printing carriage platform revolving around accessibility – the goal is to give the power of choice to the users by enabling as many options for carriage hardware as possible.”

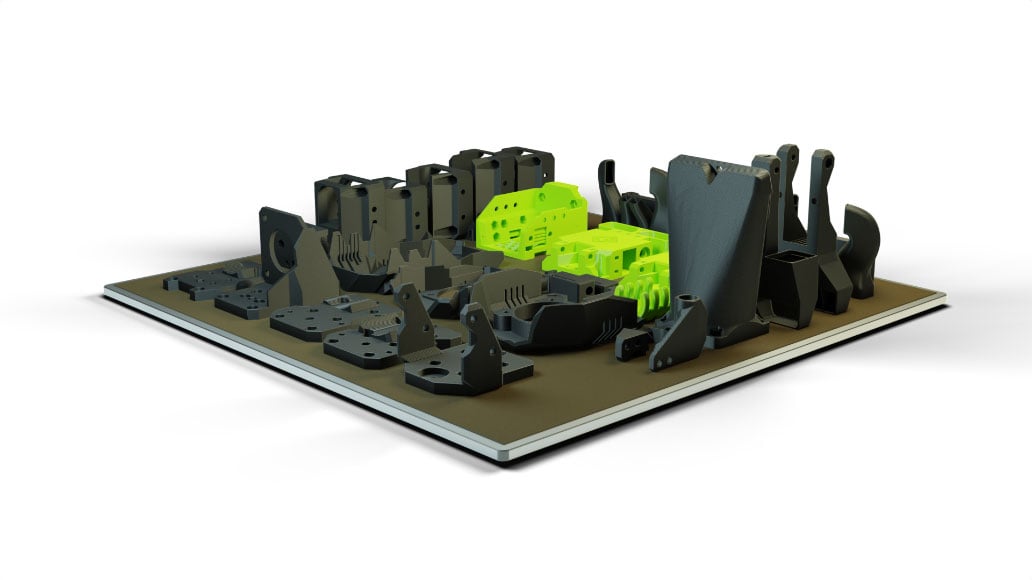

It works like this: Choose the parts that correspond to the extrusion system hardware you have on hand, then 3D print the parts – ideally in ABS or ASA material, so each piece has the dimensional stability and robustness to work reliably. Assemble it, and then 3D print with it.

How Does EVA Work?

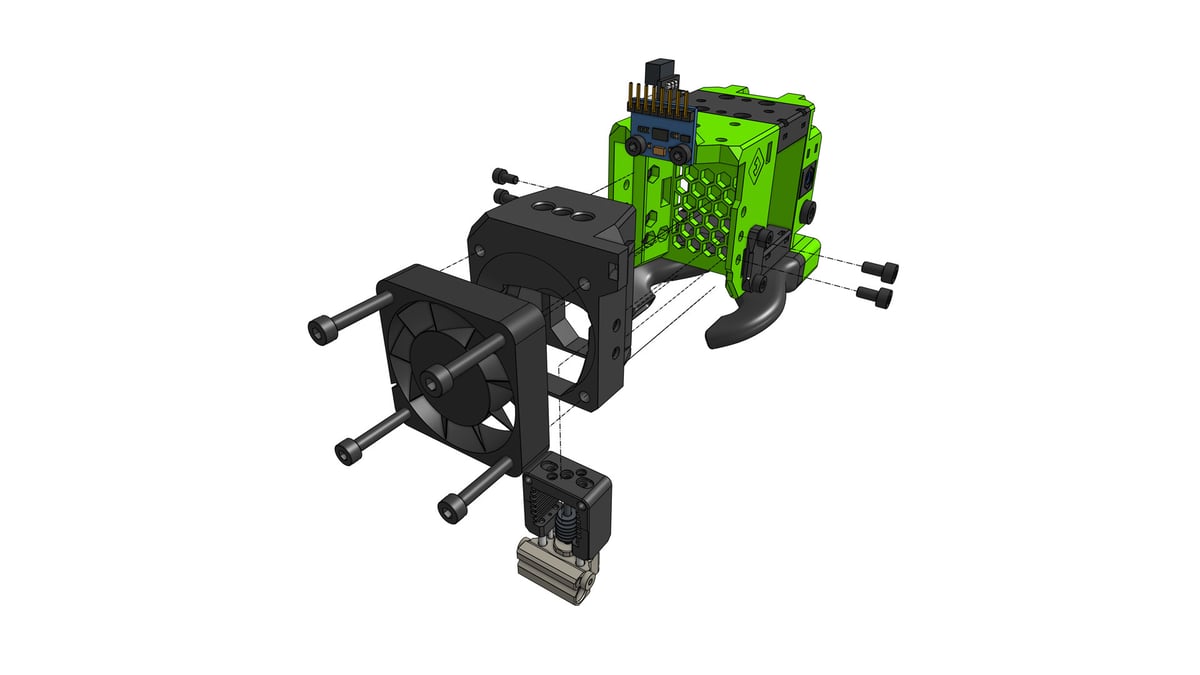

Every EVA carriage consists of four main components: a universal ‘front’, ‘top’, ‘bottom’, and ‘back’, with configurable options to fit popular types of extrusion system hardware.

Your hotend fits into your choice of ‘front’ part. There are many different parts to choose from, including hotends such as the E3D V6 and Slice Engineering Mosquito Magnum.

Your extruder mounts in a corresponding “drive” part, which attaches to the top and front printed elements. EVA supports many popular extruder types, such as Orbiter, E3D Hemera, Bondtech LGX, and more.

Then there are other modular parts, like a range of cooling fan ducts (these fit onto the ‘bottom’ piece), guide pieces for cable management, and mounts for bed leveling probes. There’s even a range of X carriage end stops available to fit mechanical or optical switches.

The extruder couples to the hotend with a short length of PTFE tube, and the entire EVA assembly is held together with easy-to-source hardware such as M3 bolts and brass heat-threaded inserts, which makes it suitably robust, but serviceable when needed.

EVA Project Progress

Now on its third major iteration, it’s quite likely EVA’s community has already contributed designs for the hardware you want to use. This gives you a nice, configurable ecosystem of parts, saving you the hassle of designing and validating your own designs. Just print the bits you need, assemble everything, and fit it to your machine.

Of course, if you’re savvy with CAD design, you can contribute your own designs (or iterate on existing ones) for the community to benefit from. Yay, open source!

Will EVA work with my 3D printer?

As always, it depends. EVA is designed specifically for MGN linear rails – the type you find in RatRig or Voron builds. This project is an offshoot from the RatRig project, after all.

Generally speaking, Core XY and Cartesian printers are supported, and there are also variants available for IDEX 3D printers. It’s well within the realms of open source possibility for you to design adaptors and other parts to add compatibility for other popular machines like those from Creality, which tends to use the more economical V-slot-based carriage system.

How to get involved with EVA

Besides the website, there’s also a YouTube channel where major updates are posted. If you do need assistance, a dedicated community on Discord is there for you to lean on.

Open Source Tip Offs

Have you seen a noteworthy open source 3D printing project? Tip us off @all3dp on Twitter or by mail at editors@all3dp.com, and we’ll consider covering them.

Lead image source: EVA

License: The text of "EVA Open-Source Modular Carriage System: A Closer Look" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.