The SMuFF (Smart Multi Filament Feeder) is an open-source extruder upgrade for hobby-level FDM 3D printers. It enables you to mix-and-match materials with different colors or properties in a single print.

There have been different approaches to multi-extrusion 3D printing through the years, falling into two main areas: dedicated extrusion and material splicing. Multi-extrusion setups like the Jubilee tool changer use a dedicated extruder for each material used. The splicing method feeds different filaments through a single extruder, and the SMuFF falls into this category. Perhaps you’ve already heard of Palette or the Prusa MMU, which work in a similar way to the SMuFF.

According to the project website, the SMuFF can “replace your standard extruder drive gear and make it a ‘Bondtech style’ dual-gear extruder,” which means improved filament transport, faster printing, and better reliability with flexible materials compared to a Bowden system. It uses a dedicated controller of its own – an SKR mini. This has a G-code interpreter built in and can run on your choice of 3D printing firmware, including Marlin 2.0, RepRap Firmware, or Klipper. There are also SMuFF integrations with popular platforms like OctoPrint, using a software plug-in and a spare USB port on your host device for serial communication.

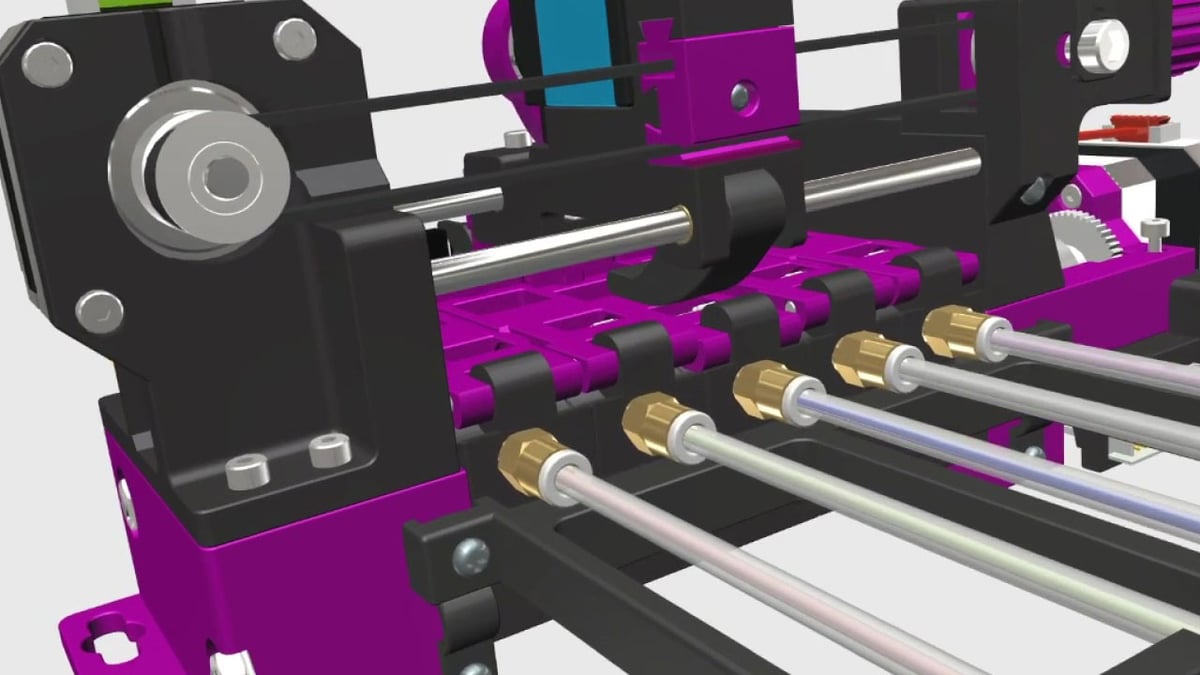

Besides 3D printed parts, a SMuFF comprises of servos, gears, bearings, brass heat threaded inserts, smooth rods, stepper motors, belts, and micro switches. These are parts any 3D printing nerd worth their salt probably has on hand already. There are also optional upgrades, like a cutter module to improve reliability by removing misshapen filament tips, and even Neopixel LEDs to use as status lights, or just to animate and look pretty.

How Does The SMuFF Work?

A belt-driven sliding carriage slides over the selected material and locks onto it using a “lid,” where it engages with the extruder teeth. The material then advances toward the nozzle via a Bowden tube.

The SMuFF can work as a Bowden-style extruder or as a feed to a direct extruder setup. It can hand the material over to the main extruder and retract it when a material change occurs, before moving to the next material.

The SMuFF’s capabilities can grow as you gain experience using it: It’s possible to start with a three-material configuration, then scale up as you see fit by adding and swapping some components around. It works with a maximum of 12 materials – more than you need to cover most 3D printing use cases.

The SMuFF V6 has undergone major improvements, including a more compact footprint, sturdier mounts, and a “monorail” sliding carriage to position itself over the selected material. A comprehensive assembly guide (178 pages!) detailing the build process was recently released.

Of course, there’s more to the SMuFF than just the hardware – it needs software to configure filament color transitions and other such things. It seems possible to do all this using PrusaSlic3r, which can also be used to create purge blocks for sharp color transitions that prevent undesirable color mixing in your print. This is assuming color mixing is what you’ll use the SMuFF for – a large portion of the community uses it for this purpose.

Who Is Responsible For the SMuFF?

The SMuFF project was founded and is maintained by Technik Gegg. To keep up with the latest developments, you can follow the SMuFF development blog.

Try It Yourself(?)

Beware that this is more than a hobby-level weekend project. It requires commitment and understanding of mechanical principles to get working well. If you don’t have these, you’re probably setting yourself up for some major throw-your-project-out-the-window frustration. If you’re skilled with mechanical engineering (or just really patient), perhaps it’s a project to try – and even contribute to.

Open Source Tip Offs

Have you seen a noteworthy open source 3D printing project? Tip us off @all3dp on Twitter or by mail at editors@all3dp.com, and we’ll consider covering them.

You’ve read that, now read these:

Lead image source: SMuFF

License: The text of "The SMuFF Multi-Material Extruder: A Closer Look" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.