Having arrived a few days ago, we’re busy getting underway with Prusa Research’s latest 3D printer: the Prusa Core One.

It’s the company’s next CoreXY 3D printer, and the first we would consider a proper consumer machine, with a ~$1,200 MSRP for the fully assembled unit set to compete directly against the still-popular Bambu Lab X1C – but notably manufactured in Europe.

That Prusa has managed to match the price is quite a feat – the assembled and virtually ready-to-run Core One is $1,199, while the kit version, coming soon, just scrapes under the $1,000 mark at $949. Owners of the MK4S will eventually be able to upgrade their machines for less than half the price of the kit Core One.

The company has released other CoreXY systems, of course. The Automated Farm System (AFS) is kitted out with mini CoreXY printers, and the toolchanging Original Prusa XL is a machine we’ve wholeheartedly recommended in a few categories. But, with an MSRP starting at ~$2,500 for a pre-assembled unit, the XL is a decidedly prosumer machine.

The Core One is set to be steep competition for Bambu Lab’s flagship machines. The hardware’s approachability is, overall, in a much better place than Prusa machines were when that green giant stepped onto the scene almost three years ago.

The company’s signature toolhead, the Nextruder, has helped eliminate much of 3D printing’s formerly steep learning curve with its “always-perfect first layers”, and other gradually improved user-friendliness. Even connecting to Wi-Fi has been pleasantly streamlined with an NFC setup process via a Prusa app, which was introduced with the MK4S just this past summer.

The company’s software, Prusa Slicer, has also steadily improved, even taking cues from Bambu Studio (which is based on Prusa Slicer) by implementing workflows that will be familiar to Bambu users, like multi-bed slicing. The release seems exceptionally well-poised for Prusa to take back its lunch money. And with fortunate timing to boot, given the Bambu Lab controversy immediately preceding the Core One release.

Functionally, getting the Core One’s first print going is as streamlined as we found it with the MK4S, with a few automated calibration routines and only minor user involvement to test the load cell and filament sensors.

It’s great to see a Prusa machine enclosed and in such a tight form factor. The large enclosure that has been installed around our MK4S is not jiving with my 6-square-meter home office, while the Core One slots comfortably onto my shelving unit. Prusa says the Core One takes up 50% less space than that previous combination, which is remarkable for the 30% increase in build volume it offers.

It’s a small thing, but I really like how the plug doesn’t stick straight out the back of the machine, removing valuable clearance. It goes to show the detailed thought Prusa’s team put into how this system can be space-saving.

And the company has taken steps to make what space it does take up useful. Even before Core One units were shipped out to reviewers like us, the community had started modding around the system’s unique recessed design thanks to STEP files released ahead of the printer. We love the SKADIS mod that Prusa shouted out in its recent blog post, and we’re excited to find more creative uses for the recesses and test Prusa’s claims of a fast, exclusively bed-heated chamber – which it partly credits to the recessed design minimizing useless volume.

Despite the smaller size, the Core One’s 220 x 250 x 270 mm build volume exceeds the MK4S’ by 30%, and Prusa says it’s even about 15-20% faster. Slicing using Prusa Slicer and early-access profiles shows predicted speed improvements of ~13% for Prusa’s Rocket Engine MK4 sample part using a default 0.20 mm “SPEED” profile with Prusament PLA – 6 hours and 33 minutes, down from 7 hours and 35 minutes. A Benchy shows ~8% faster at 33 minutes down from 36, with our test’s real print time clocking in at 43 minutes (which includes time heating from cold and pre-print checks).

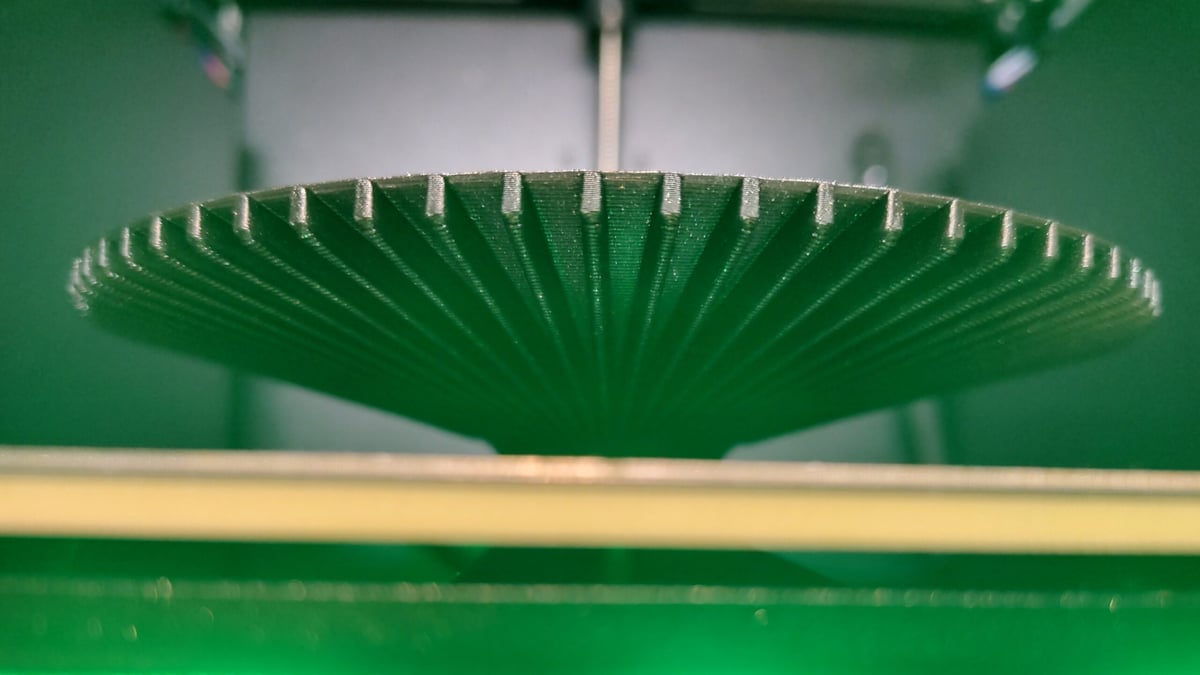

The powerful cooling Prusa introduced to the Nextruder with the MK4S has carried forward to the Core One, with its 75º overhang capability appearing alive and well. We printed off a Scandic Plate torture test with Prusament Galaxy PLA to the same impressive results we saw with the MK4S.

It would be reasonable to worry that the enclosure could hurt the performance with low-temperature materials like PLA – something we saw in our MK4S overhang shootout – but Prusa has been touting the system’s active chamber temperature control thanks to its dual enclosure fans and a top vent. The company said during the Core One’s Formnext reveal that, in testing, it maintained a 27 ºC chamber temperature with its door closed. We printed this first Scandic Plate with a closed door and open top vent, and intend to throw a few third-party materials at it in the coming days to compare to our shootout. If the same performance carries forward it’ll be a treat not to have to remember to open the printer door and top cover.

All that good stuff said, we’ve encountered one minor wrinkle when setting up the (optional) Buddy3D camera. The overall design is great; it’s a convenient 3D printed case with magnets that secure it to the upper left cover of the machine’s enclosure, and plugging it in uses a simple pre-routed USB-C cable. Getting the camera on the local network is the issue.

If a recent thread on Prusa’s forums is to be believed it seems like special characters in the network SSID and/or password are the culprit. Without any interface from the camera (it’s set up by scanning a QR code), it’s hard to tell what the problem is. Maybe it hasn’t picked up the QR at all? I really can’t say yet, but the forum conclusion seems plausible.

It feels like this is a teething issue, rather than anything systemically wrong; as Prusa makes its machines increasingly convenient to set up – that appliance-like quality that Bambu Lab introduced to the conversation – things like this become a little more conspicuous.

That said it’s important to note the Buddy3D camera is an optional add-on to the Core One, and Prusa provides solutions to use other cameras with the 3D printer.

There’s sure to be a lot of detailed looks at the Core One up already, but we’re taking our reviews slow and steady these days. It’ll be a while before our full review is up.

If you have any burning questions about the Core One and its performance, email editors@all3dp.com or comment here, and I’ll do my best to check it out and share an answer lickety-split.

License: The text of "Prusa Core One: Hands-On & First Impressions" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.

Stay Informed, Save Big, Make More

Stay Informed, Save Big, Make More