The realm of 3D scanning, particularly in the automotive industry, has experienced exponential growth in recent years. As the demand for precision, customization, and rapid prototyping rises, the fusion of modern technology with vintage designs has emerged as an exciting frontier.

But 3D scanning also offers big advancements on even smaller scales, including the creation of miniature models and prototypes. One such project that has generated considerable attention in this domain is “peel x peel.”

The “peel x peel” initiative stands as a beacon of innovation, perfectly marrying nostalgia and advancement. This endeavor is not just a testament to technological prowess but also an ode to the iconic Peel P50, a three-wheeled microcar originally made in the 1960s. Led by peel 3D , the Canadian 3D scanner manufacturer, the team managed to digitize and reproduce this vintage vehicle as a miniature.

Leveraging its own peel 3 3D scanner, the team collaborated with several partners to bring this legacy into the future. Let’s take a look at how the “peel x peel” initiative came about, and how both 3D scanning and 3D printing technology were used to push this innovative idea passed the finish line.

The Conception and Vision of “peel x peel”

At its core, “peel x peel” is a blend of reverse engineering and contemporary design. By leveraging the capabilities of the peel 3 scanner, the objective was clear: resurrect the iconic Peel P50 into the digital realm, making it available for 3D printing.

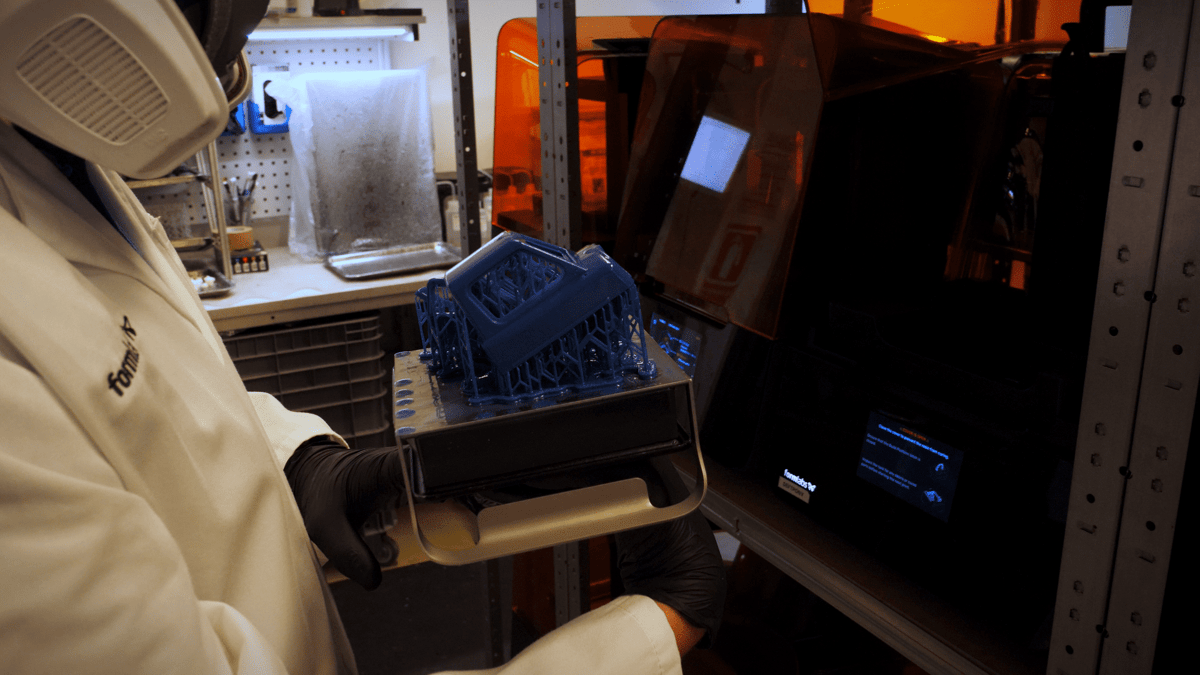

This ambitious project, punctuated with challenges and triumphs, led to a collaboration with Creaform Engineering Services. Their combined expertise resulted in meticulously crafted miniature models of the Peel P50, each echoing the vehicle’s vintage charm. Thanks to Formlabs in Germany, these digital designs transitioned from bytes to tangible beauties.

The vision behind this project was not merely technological. It’s a mission to bridge the realms of 3D scanning, reverse engineering, and 3D printing in a manner that’s engaging, educative, and delightful.

The peel 3D scanner and its reverse engineering software, currently available at a discounted price of 9,990 USD, have been turning heads in the industry, redefining reverse engineering. This device isn’t just another scanner; it’s a paradigm shift. With its ultra-ergonomic handle designed for comfort, a slick LCD screen for intuitive interactions, and haptic feedback ensuring seamless scanning of challenging areas, it promises an unparalleled user experience.

One of its standout features is the peel.CAD software. Tailored for reverse engineering, this software effortlessly transforms scans into CAD-ready files, making it an invaluable asset for professionals. With a design focused on simplicity, fewer clicks, and efficient workflows, it’s clear that the peel 3.CAD scanner prioritizes user experience without compromising on precision and capability.

How Collaboration Fuels Inspiration

Aside from showcasing the prowess of 3D scanning technology, this project also demonstrates the importance of collaboration between different subject matter experts. Partners like Solidprint in the UK were pivotal in sourcing the rare Peel P50, while P50Cars, rejuvenating the legacy of the original car, made it possible to capture with a 3D scanner. Formlabs, the renowned 3D printer manufacturer, assisted at the tail end of the project, ensuring each model retains the iconic design and intricate details of the original.

Catering to a broad spectrum, from product design to everyday enthusiasts intrigued by 3D technology’s potential, “peel x peel” showcases a end-to-end solution from ideation to production. It highlights the transformative potential where 3D scanning technology, design, and 3D printing intersect. Beyond its technical accomplishments, the initiative evokes the wonder of the Peel P50 and the infinite possibilities within the realm of 3D scanning and printing.

While reverse engineering isn’t exactly novel, the “peel x peel” project stands out by making it accessible and open to all. By offering miniature models resulting from the 3D scan to the public, it sets a standard that evokes open-source technology and the community that this technology was founded upon.

Finding a Peel P50 in and of itself, given its rarity, was an obstacle that required time and patience. Leveraging connections and their collaborative spirit, the team was able to locate and source one of these specialized vehicles for the project.

As part of its outreach, the “peel x peel” journey will be showcased in two YouTube videos, offering viewers a behind-the-scenes look into this technological project. For those inspired to embark on their 3D printing journey, the project’s STL files will be accessible for download, ensuring the essence of “peel x peel” can be experienced by all.

Driving Towards a Brighter Future

Ultimately, “peel x peel” project serves a dual purpose. It’s a nod to the legacy of the Peel P50 while spotlighting the capabilities of peel 3d and its partners. As businesses and individuals navigate the expansive world of 3D scanning, reverse engineering, and printing, projects like these offer a glimpse at what’s possible for professionals and hobbyists alike.

“peel x peel” offers a look at how 3D scanning technology fuels both innovation and collaboration. It encapsulates the power of technology to transform, both in recreating a vintage marvel and in providing insight into the future of design and production for projects both large and small.