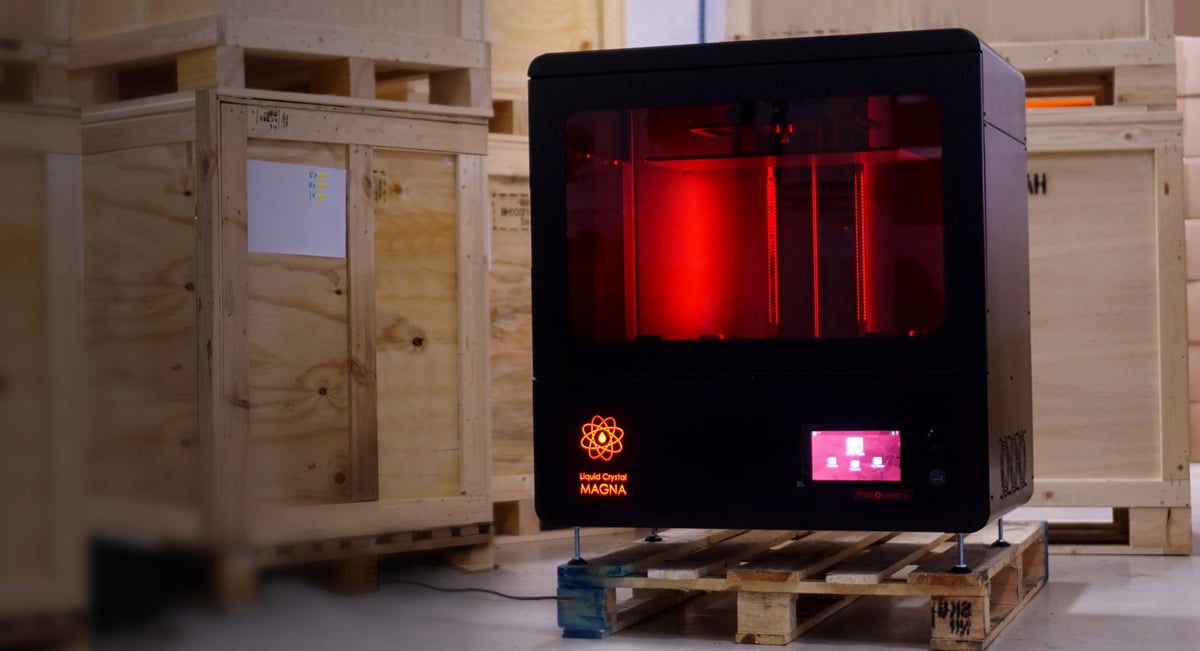

UK-based resin 3D printer maker Photocentric just launched what it says is a completely re-engineered desktop resin printer. The new LCD screen-based Liquid Crystal Magna v.2 is “significantly faster” than the previous version, Photocentric says, and features upgraded electronics, including a new control system and interchangeable platforms, all aimed at improving reliability and performance. On the outside, it looks the same as the previous version.

If you’re not familiar with LCD resin printing, it doesn’t use a laser to trace out each layer like stereolithography (SLA) from 3D Systems or Formlabs. Instead, it’s nearly the same as digital light processing (DLP) in that it also flashes complete layers at the resin tank for faster overall build times, but with the UV light coming from an array of LEDs shining through a liquid crystal display, not a projector (as with DLP). A screen acts as a mask, revealing only the pixels necessary for the current layer. As such, no special device is required to direct the light, as is the case in both SLA and DLP. Fewer moving parts can result in less maintenance.

When it comes to speed, Photocentric says the Magna v.2 prints at 16mm per hour depending on the resolution. By way of example, the company says 36 custom dental trays (80-mm Z height) at 250-micron layers can be printed in 1 hour 13 minutes, compared with 2 hours 22 minutes on the previous version of the LC Magna. So, twice as fast as the previous version of the Magna.

Tech Specs

- Build volume: 510 x 280 x 350mm

- Print layer thickness: 25, 50 and 100µm.

- Resolution: 4K screen. 3840 x 2160 px

- Print Speed: 16mm per hour

- Cure Speed: 2 seconds per layer at 100um

- Light output wavelength: 460nm

- Price: ~ $22,000 – $26,000

- Software: Studio, Additive (optional)

Another new feature is the quiet, 6-fan cooling system, which the company says enables faster production time, particularly for small models. A new software integration ability enables communication with MES systems, such as 3YourMind. There’s also a new quad-core processor with a 7-inch touch screen.

The idea behind the updates is to position the Magna v.2 as a production resin printer for batch volumes. The company says its new “hydrophobic platform” also boosts productivity and further reduces material waste. The platform has a “hydrophobic coating to increase processing speed and yield, and enables easier platform cleaning,” Photocentric says. By hydrophobic, we can only assume the company means parts will be easy to remove from the build platform.

The Magna v.2 is not an open materials platform but Photocentric has partnered with Forward AM, BASF to make a wide range of materials available, including its line of Daylight resins. “Daylight is a lower energy, longer wavelength light that travels further and ensures more reliable polymerization than UV,” Photocentric says. “Daylight unlocks the problems of curing dark-colored or particle rich formulations.”

The Magna v.2 features the same large build volume as the previous version, 510 x 280 x 350 mm, and the same patented Blow-Peel technology, that acts as a pressure release to ensure parts are not damaged as the cured layer pulls away from the liquid resin.

The Magna v.2 comes with Photocentric’s Studio software suite. The Photocentric Additive software is available as a separate license at $10,500 per year. The Additive software, only available on Magna v.2, has some novel features, including the ability to select surface textures during the slicing state from a database of more than 5,000 options. You can upload your own texture or logo. You can also run a quality check and models.

License: The text of "Photocentric’s New Resin Printer Doubles Speed, Targets Production" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.