If you walked the halls of Formnext thoroughly this year, you’d be forgiven for completely missing Phrozen’s new 3D printer. Tucked away in the corner of the company’s booth, itself a modest presence on hall 12.1’s quieter outer wall, the Arco drew little attention and stood more as a conversational afterthought. Something for reps to strain an over-the-shoulder acknowledgment at, should you happen to spot it.

But we knew it would be there, and we chatted with Phrozen co-founder and CEO Ray Wu for some early details.

The Arco “monocolor” FDM has been in development for a few years already, explained Wu, a timeframe that’s inescapably linked with the emergence of Bambu Lab – which you can’t help but think of when you see the prototype complete with its multi-material station. “You know, last year there’s a buzzword, ‘fast’, for FDM, ‘multicolor’ for FDM, and we see some opportunities here.”

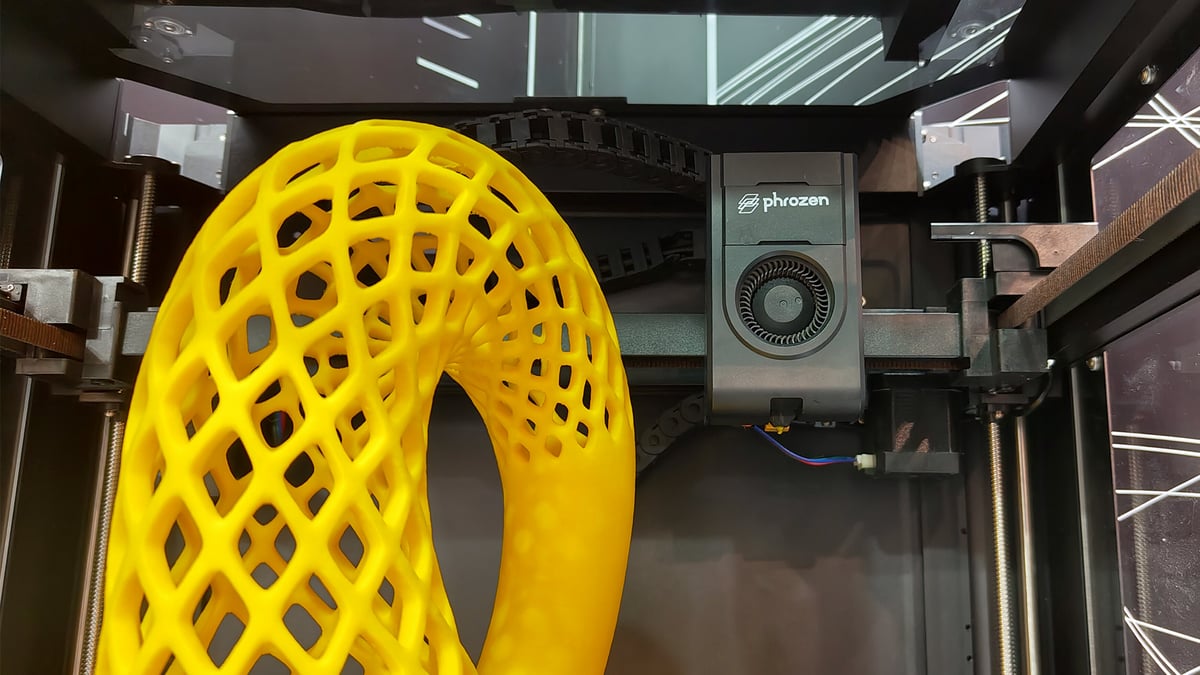

“We do two major changes on this. [The] first one is that we make it faster than the current competitors on the market.” While the Arco unit at the show was just a prototype, not operational or functioning, the motion system and general design were clear to see. In addition to a heavy base and the print plate being fixed at the bottom of the machine, the Arco uses a flying gantry CoreXY, with the print head gantry moving down to the print plate rather than the plate up to the nozzle (think Voron 2.4 for a well-known example of this motion system). Doing this, Wu explains, increases the stability of the system and reduces wobbling.

It’s claimed that, in the lab, the Arco is capable of 800 mm/s print speeds, though Wu concedes that it’s unlikely that Phrozen will use this number in its marketing, instead opting to match the 600 mm/s used by what they see as the competition. “But, our acceleration is up to 30,000 [[mm/s]], which is far faster than others. You know, [the Arco] has just a 30-centimeter square build area, so you need a high acceleration to reach the maximum speed.”

The second element that differentiates the Arco, says Wu, is the printer’s thermal management and design of the hot end. While not much detail is given about the (proprietary) hot end, it is said that the distance between the extruder feed point and the heating element is reduced to just 10 mm, which allows for fast printing of TPU.

Other tidbits about the Arco are that it will use Klipper, it has the mounting threads to add an enclosure (but by default, is not enclosed), and the company is developing its own slicer to handle the multicolor aspect of printing. The Arco fills a gap in the company’s lineup, joining a portfolio of products that includes resin 3D printers of all sizes, a vast resin material offering, and accessories, including the Sonic Saber ultrasonic knife (which Wu tells us incidentally, was conceived for FDM post-processing).

We don’t have any more details about the multi-material system, but we likely won’t have to wait long to find out more. Phrozen aims to launch the Arco next year, with a Kickstarter campaign to launch the printer some time in the first quarter of the year. Being a prototype and some steps removed from final production, we wouldn’t be surprised if some specs and features change between now and the Arco’s eventual launch. We’ll be keeping track.

You’ve read that; now read these:

License: The text of "Phrozen Quietly Revealed Its First FDM Printer at Formnext" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.