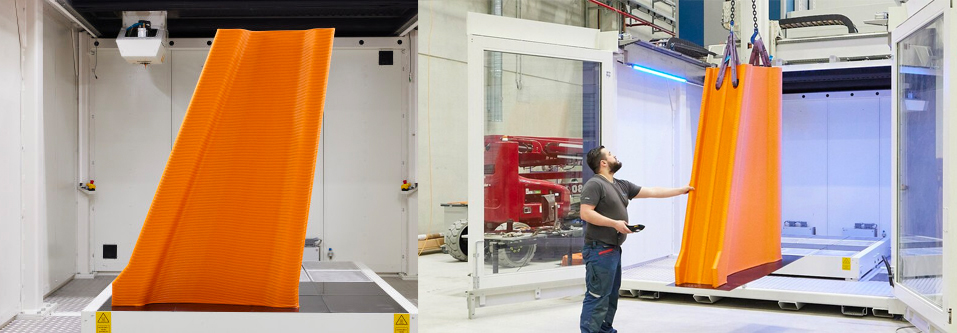

At nearly twice the size of almost all other fully enclosed heated FDM 3D printers, the new PowerPrint from KraussMaffei is designed for applications from mold making and facade panels to pipes, fittings, and prototype construction parts.

The massive 2 x 2.5 x 2-meter build volume fits the PowerPrint in between large-format FDMs and robotic arm 3D printers. (For reference, you could fit about 60 UltiMaker Method Xs inside the PowerPrint’s chamber.)

Couple the size with a high-temperature (400ºC) extruder, heated bed (140°C), and a heated (60ºC) vacuum chamber, and this new 3D printer can deliver parts in a wide range of thermoplastics, including ABS, carbon fiber reinforced nylon, ASA, TPU, PP, and recycled options.

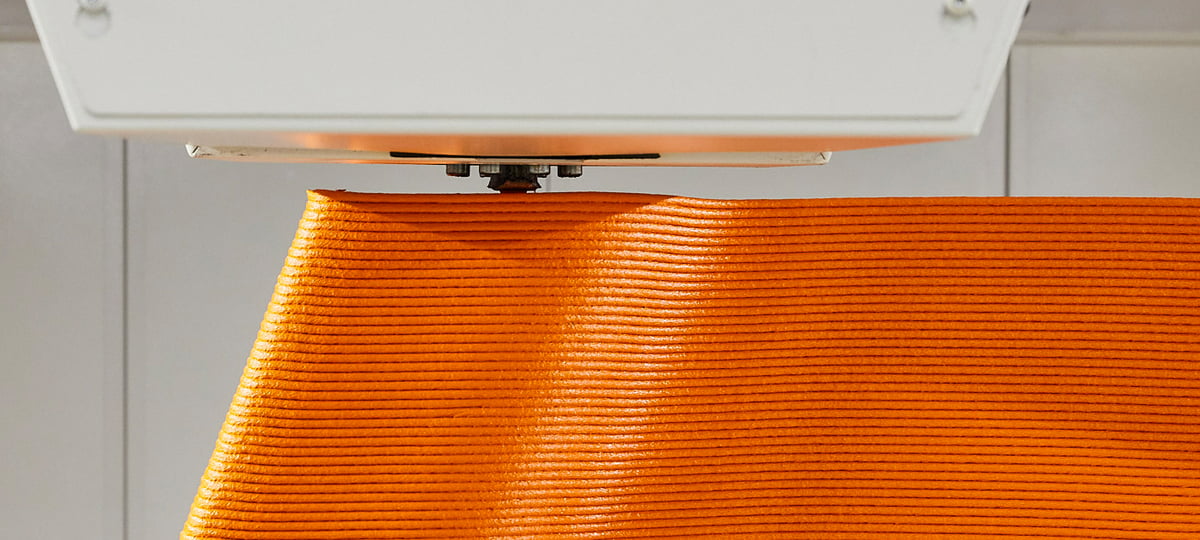

Rather than filament, PowerPrint uses economical pellet materials, which also facilitate faster printing. The machine’s Printcore extruder is available in two sizes for output capacities up to 30 kg per hour.

The extruder, which features various nozzle sizes from 2 to 20 mm, is guided by what KraussMaffei calls linear robot axes that “enable a high production speed and exact printing,” the company says. The maximum travel speed of the extruder is 300 mm/s.

KraussMaffei, the German plastics processing and machinery manufacturer acquired by Chinese chemical group National Chemical Corporation in 2016, launched its 3D printing division in late 2022 with the unveiling of the PowerPrint at the Formnext Expo. The machine became available this week.

If you’d love to get your hands on massive carbon fiber prints but aren’t in a position to become the owner of your own PowerPrint just yet, you’re in luck. KraussMaffei is offering an on-demand print service.

Tech Specs

- Technology: FDM

- Print volume: 2 x 2.5 x 2 m

- Speed: 30kg/h

- Nozzle sizes: 2-20 mm

- Max. extruder temp.: 400℃

- Chamber temp.: 60℃

- Max. bed temp.: 140℃

- Materials: ABS, carbon fiber nylon (PA), PET, PLA, ASA, TPU, PP, +

- Material format: Pellets

License: The text of "New PowerPrint FDM Boasts 10.5 Cubic Meter Build Chamber" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.