In recent years, extrusion-based 3D printing – often referred to as fused deposition modeling (FDM) or fused filament fabrication (FFF) – has become a dominant force in the market. The number and quality of affordable FDM printers is steadily increasing. According to Statista, in 2021, the most extensively employed 3D printing method was FDM/FFF, with over 70% percent of participants using this technology in-house.

The process of selecting a suitable material for particular applications is inextricably linked to the manufacturing process employed. At present, widely used extrusion-based 3D printing materials such as PLA and ABS don’t offer the required performance for various end-users. Designers frequently encounter the issue that the resulting 3D printed parts do often not satisfy the product quality demanded for the targeted applications. The major reason for this is the wrong choice of 3D printing material.

Polypropylene: The Material of Choice

Unfortunately, the number of materials that offer the desired mechanical properties is limited. But polypropylene (PP) has already proven its wide applicability in numerous technical and medical technology products, representing one of the most promising additive manufacturing materials on the market.

PP has a broad property profile that includes very good break-resistance, low density, and high chemical resistance, which is important to fabricate lightweight and robust parts. In addition, PP is safe to use for parts that come in contact with the human body and is sterilizable, which is especially beneficial for medical technology. Parts that are 3D printed with PP can also be cleaned easily in dishwashers and are microwave resistant. Furthermore, PP can be recycled or used as an energy source.

FDM 3D Printing with Polypropylene

Remarkably – despite its attributes – PP is not yet widely used in additive manufacturing. Most common PP grades are difficult to 3D print in terms of interlayer bonding, warpage, bed adhesion, as well as limited availability of a reliable support material.

To successfully 3D print with polypropylene, three critical components are necessary:

- The material must have inherent low warpage and high interlayer bonding strength.

- The surface on which the part can be directly printed has to allow a reliable 3D printing of PP parts and permit non-destructive and residual-free removal of the finished object without any additional chemicals.

- Support material is required for printing complex structures with unsupported elements, such as voids, windows, etc. The support material should also be easily removable without creating additional waste.

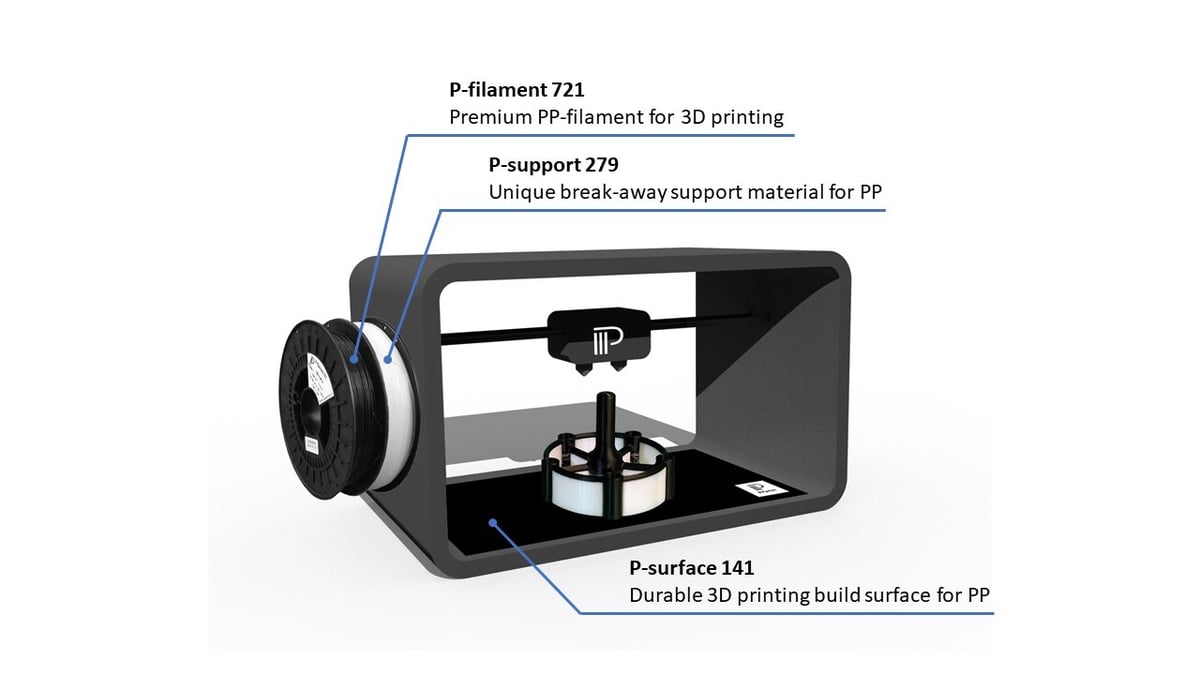

The German company, PPprint GmbH, has solved these issues by developing a product portfolio that enables successful 3D printing of PP parts in various shapes and complexities utilizing commercially available 3D printers (Figure 1). Its current product portfolio includes the PP filament family “P-filament 721”, available in the diameters of 1.75 mm and 2.85 mm. “P-filament 721” is commercially available in natural, white, black, and nine other colors.

P-filaments 721 are hydrophobic and therefore do not require drying before 3D printing. The filaments offer low warpage and very high interlayer bonding strength. 3D printed parts using “P-filament 721 natural” are certificated for biological safety according to DIN EN ISO 10993-5, which is crucial for medical devices that come into contact with the skin. Additionally, PP pellets are available for large-scale industrial additive manufacturing.

Furthermore, PPprint developed a special 3D printing build surface “P-surface 141” that enables reliable 3D printing and avoids common bed adhesion issues. 3D printed parts can be easily and cleanly detached from “P-surface 141” upon heating.

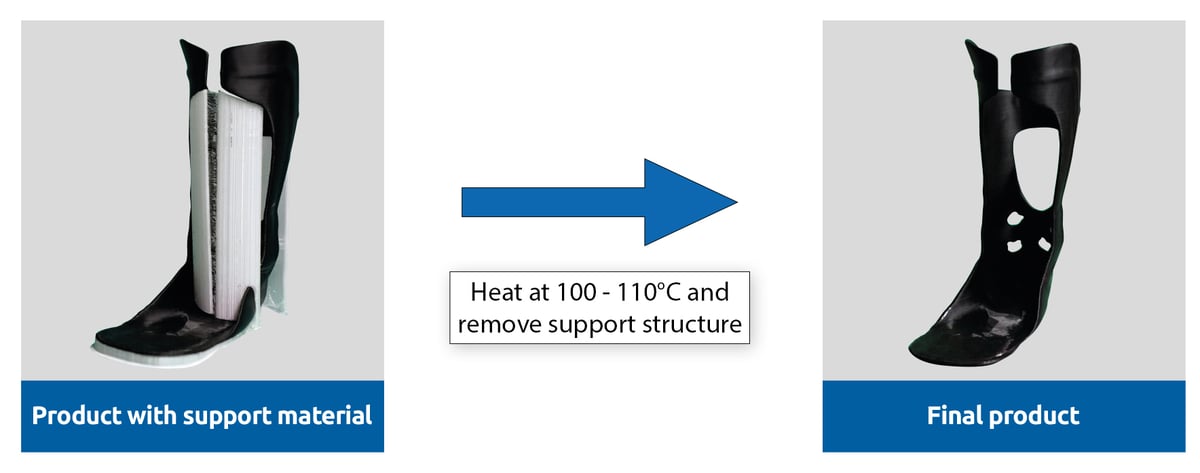

Another product the company developed is the novel break-away support material. The support material “P-support 279” is specially engineered for PP, enabling the production of even more detailed and complex structures that contain bridges, overhangs, and openings. This support material adheres very well to PP printed parts as well as to “P-surface 141” but can also be removed easily and without residue upon heating (Figure 2).

Another recent innovation by the company is a solvent-based procedure for smoothing the surface of 3D printed PP parts. An illustrative example of the resulting treatment is shown in Figure 3.

With its current portfolio, PPprint provides all the components needed to successfully 3D print complex parts made from PP. The company also offers strong customer support and a 3D printing service for PP parts made in its own 3D printer factory.

For more information about PPprint, watch the video below or visit www.ppprint.de.

License: The text of "PPprint Polypropylene: The Best Material for FDM 3D Printing (Ad)" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.