The growing adoption of 3D printing technology has led to incredible feats in many fields, from life-saving medical innovations to breakthroughs in prototyping and end-use production. Despite the good that additive manufacturing has bestowed upon the world, the industry must also come to terms with its use of plastic that is needed to create these incredible solutions.

Inherently, 3D printing wastes less material than other traditional manufacturing methods, but there’s still an environmental impact that should be acknowledged and solved by industry leaders. As plastics flood our oceans and landfills, it’s crucial that we continue to shift towards more recyclable materials and more energy-efficient processes.

One newcomer to the 3D printing marketplace is already making sustainability a key part of its mission and identity. PrintBed, a US-based filament producer, wants to minimize the environmental impact of 3D printing with a new line of bioplastic-based PLA.

PrintBed PLA: Reducing Carbon Footprint in a Colorful Way

PrintBed certainly prioritizes quality alongside sustainability when it comes to the production process. While there are several bioplastic filament companies on the 3D printing market, PrintBed’s intensive and flawless production process sets them apart from the competition. Each step of production is handled by a diligent and small team based out of Detroit, Michigan – ensuring quality and care in every spool.

The process begins with sustainably sourced bioplastic material, supplied by NatureWorks, resulting in a quality PLA material with the lowest carbon footprint on the filament market.

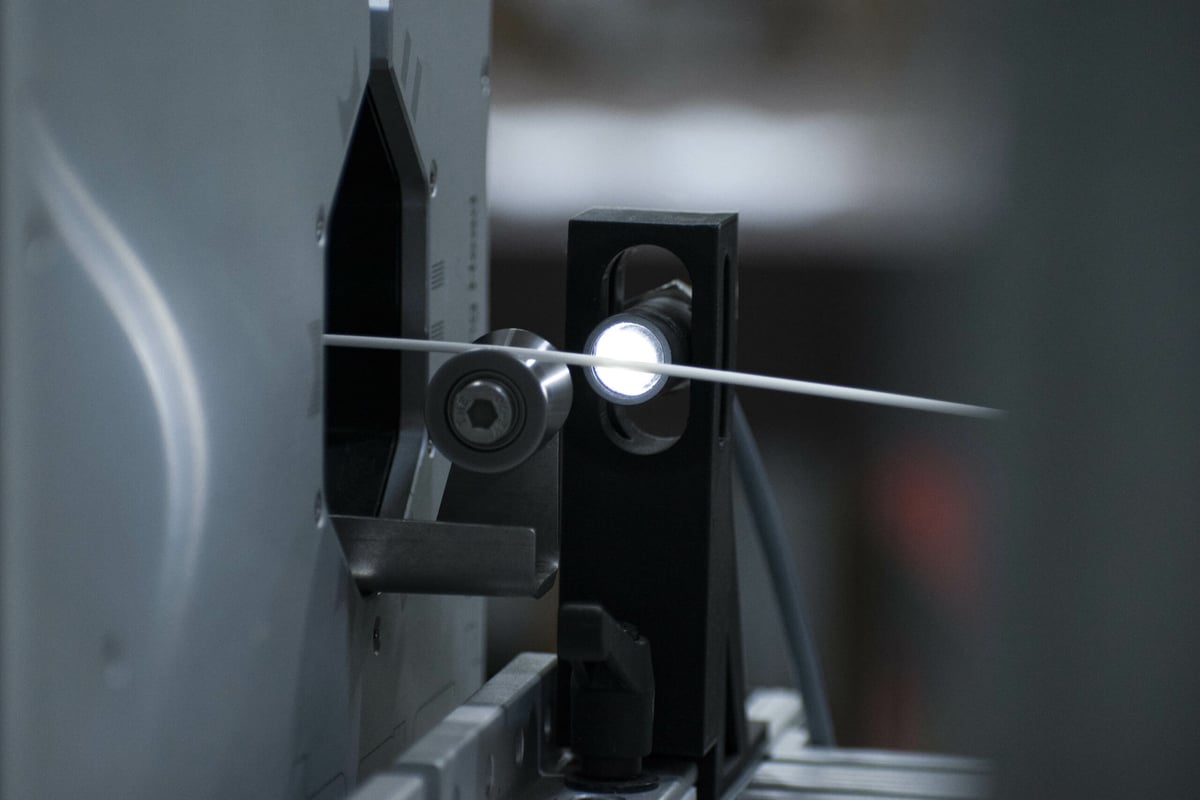

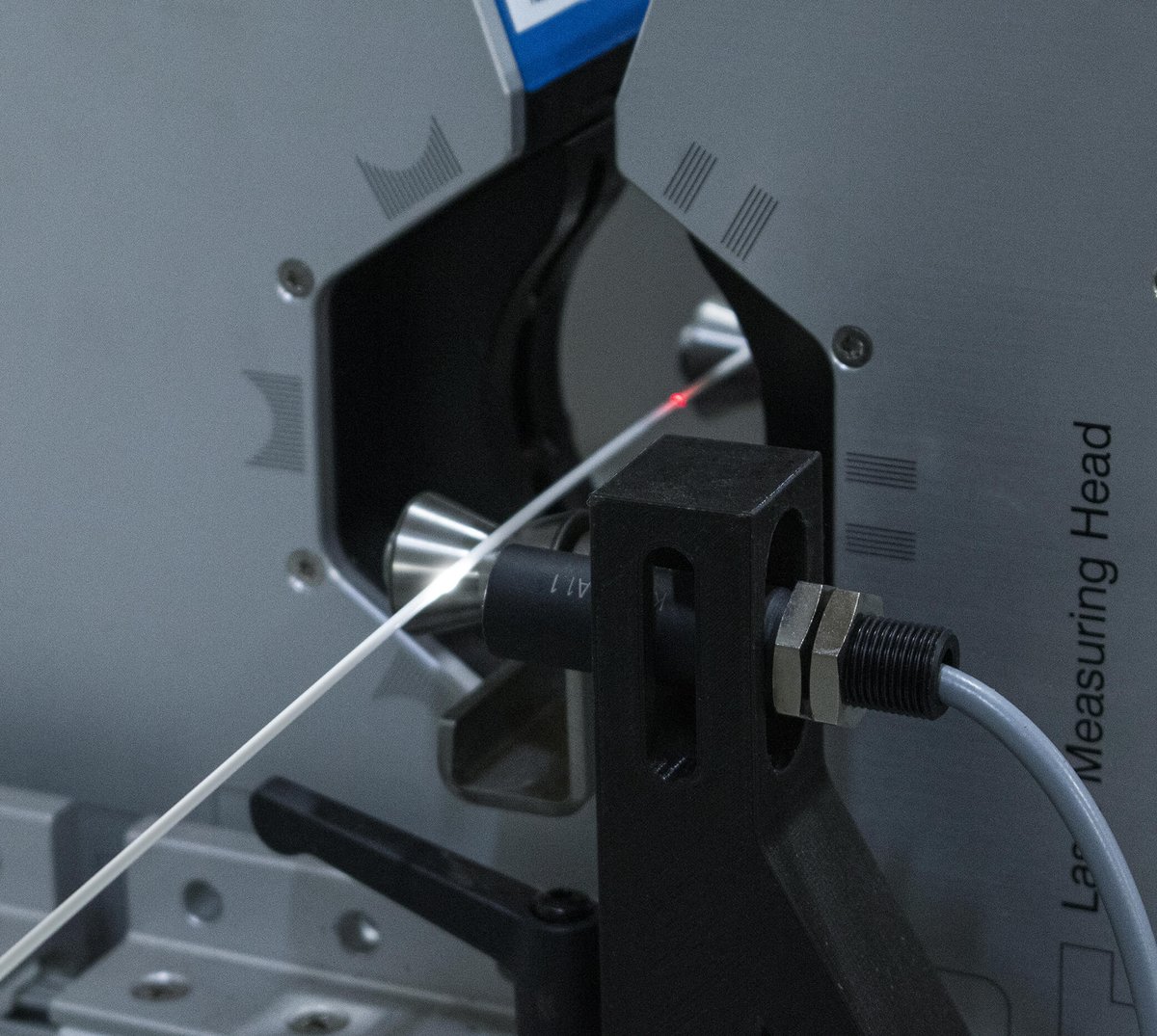

PrintBed takes this raw PLA and accurately shapes it into filament, measuring it with a 3-axis laser micrometer to ensure a tight diameter variation of 0.02mm and an ovality variation of less than 2%. Most filament producers utilize a 2-axis laser micrometer that’s more susceptible to measurement errors, leading to an extrusion rate deviation of up to 27%. The 3-axis laser that PrintBed utilizes is three times more accurate and only allows an extrusion rate deviation of 9%.

Dimensional accuracy isn’t the only part of the process that PrintBed has perfected. PrintBed leverages color recognition technology via a smart laser for high color accuracy that ensures consistency across all spools. Each of these selected filament colors are engineered to be an exact match with pantone colors. Oftentimes, filament producers fail to maintain the exact same color from spool to spool, which can lead to glaring inconsistencies in finished 3D printed objects.

PrintBed utilizes a proprietary winding system to complete each spool. A perfectly wound spool prevents any tangles or frustrating filament jams from happening during the printing process. The spool itself is fully made from recyclable and biodegradable chipboard material. PrintBed has made sure that the spool can be fully recycled once its usefulness is spent, and even encourages upcycling the spool by repurposing it in other useful ways.

Attention to detail is another characteristic that PrintBed prides itself on. The cardboard spool design is the perfect example of this. Each spool is designed to match the color of the filament it holds, and even includes a notch that showcases exactly how much material is left on the spool.

Once an order is placed, PrintBed’s small yet dedicated team work to get filament to their customers the very next day. In fact, the company claims that any order placed before 6PM(EST) will make it to their customer’s door by tomorrow. Shipping is also as sustainable as can be. PrintBed doesn’t use extra packaging or boxes. The company minimizes packaging by strapping together the filament boxes.

This entire product offering, from resin to spool, is sourced and manufactured in the United States. Keeping production domestic and in-house makes it possible for PrintBed to ship its filament overnight anywhere in the continental United States for just $5 in shipping and handling, so any US-based customer can get this filament quickly if they’re in a pinch.

While most other eco-friendly filaments come in bland, earthy tones, PrintBed has managed to produce a wide array of colorful options for customers. The producer currently offers its PLA in nine different colors, including black, white, grey, green, red, yellow, blue, purple, and orange.

At $20 per spool, customers can obtain a vibrant collection of eco-sourced filament at a reasonable price. Each spool of PLA weighs 1kg and comes in both 1.75mm and 2.85mm diameter.

When it Comes to Filament, PrintBed is Just Getting Started

Reducing the carbon footprint of plastic filament and outperforming competitors on the market have been the motivating factors for PrintBed.

“We looked at other filament manufacturers and saw them cutting corners when it came to quality control, which often results in failed or poorly executed prints. Another major issue we resolved were the endless amount of plastic spool flanges being put into the environment by other companies,” the PrintBed team stated.

PrintBed’s new bioplastic filament line was developed and released in just six months – and the company has plans that go beyond eco-friendly PLA. Another recent offering is Forge PLA, a similar material with increased strength and heat-resistant properties.

Customers will soon have access to a custom proprietary house blend that is currently in development, along with other vibrant colors and new materials in the near future. To learn more about PrintBed or purchase sustainably-minded PLA material, visit their web store here.