Most any 3D printing hobbyist has asked themselves at some point, “just how bad is this for my health?” After all, we are manufacturing – often at home – with thermoplastics. And yet, somehow, a safety certification standard hasn’t been adopted in the mainstream.

But such a standard does exist, and has since 2017. Now, Prusa Research has stepped up to be the first consumer manufacturer to certify a 3D printer under it.

Specifically, that’s the MK4 and MK4S when operated with Prusament PLA and PETG. UL Solutions, a third-party certification body, has tested those systems in use with those materials against its 3D printer emissions standard, which measures for conformation to current safety standards of UFPs and VOCs in non-industrial environments. Josef Průša, founder and CEO of Prusa Research, proudly shared the MK4 certification on X, which shows the “Greenguard” UL 2904 certificate stating the 3D printer “meets criteria”.

Great! But perhaps rather vague. Users were quick to point that out with questions about exactly which contexts the MK4 is now certified within. A Prusa blog article helps, specifying “classrooms, offices, libraries, and other non-industrial indoor settings, where proper ventilation may not be ensured,” but doesn’t elaborate much on the UL 2904 standard criteria.

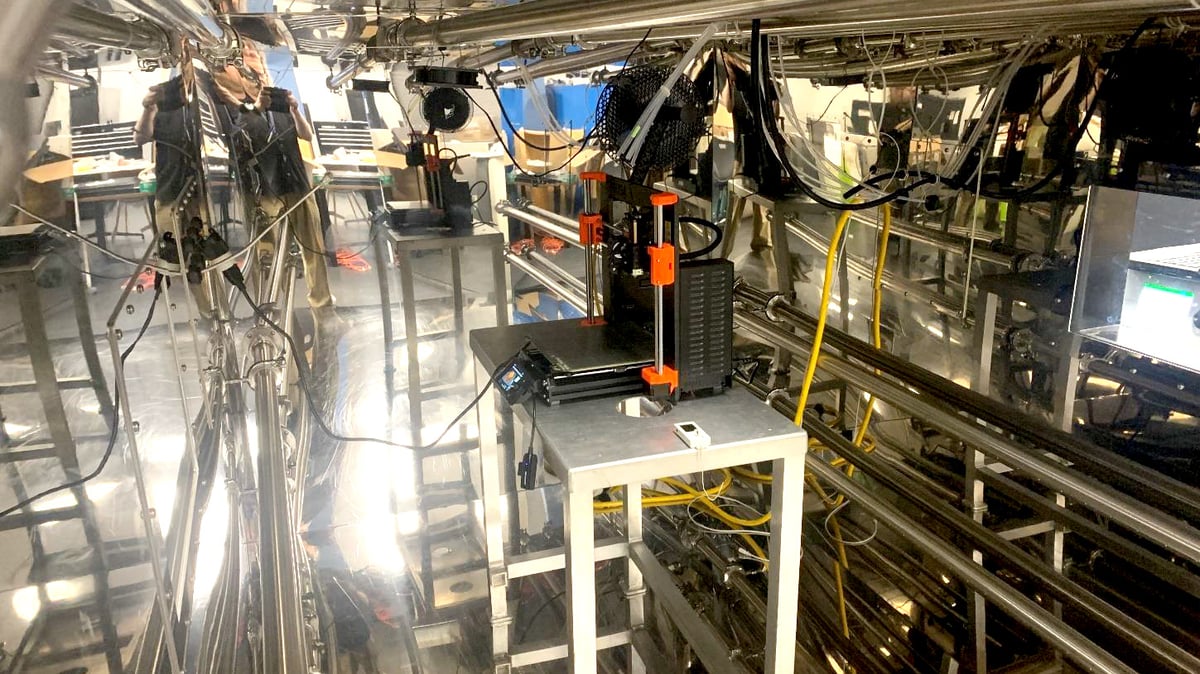

We were curious, too. If it’s not obvious, we at All3DP often 3D print things. Like, a lot of things. In what is typically an enclosed office environment. We’ve given a lot of thought to safety and, in our separate print lab, long ago installed a variety of enclosures that help keep our prints in a controlled, ventilated environment.

I was especially curious, being the sole occupant of All3DP’s Berlin office – which is conveniently located in my apartment – where I test 3D printers in a true hobbyist setting. No industrial enclosures for me. *cough*.

So, we dug around for more insight into this much-needed 3D printer certification, and spoke with UL Standards representatives about the company’s UL 2904 standard.

What is UL 2904? What is Greenguard?

If you’re new to the conversation of 3D printer emissions, here’s the basics: 3D printers emit a combination of volatile organic compounds (VOCs) and ultrafine particles (UFPs) into the air when used. UFPs are microscopic plastic particles measuring less than 300 nm that have been found to enter the lungs and, through them, the bloodstream. VOC, meanwhile, is a blanket term used to group together chemical compounds that range from relatively harmless to known irritants and carcinogens (e.g. formaldehyde and benzene).

We’ve known 3D printers output these emissions for a long time (with some materials, like ABS, suggested to output higher emissions than PLA or PETG), but research about their effects in non-industrial environments like schools, homes, and offices, and how they affect the people exposed to them has taken time to build up to a point where standards can be confidently established.

That’s what UL 2904 is: a “Standard Method for Testing and Assessing Particle and Chemical Emissions from 3D Printers” created by UL Standards and Engagement to determine whether a 3D printer’s emissions exceed the thresholds current research suggests are safe. “Greenguard Certification”, meanwhile, is the commercial testing procedure that UL sells to manufacturers to communicate the successful passing of the UL 2904 standard’s criteria to consumers.

The standard itself is, pleasantly, free for all to read and follow. You can’t download the 80-page document without paying a hefty $500 fee, but once you’ve registered for an account with UL, it’s there to freely peruse in your browser.

“Another laboratory could pick this up and run if they follow the instructions,” Scott Laughlin, UL Verification Services’ Program Manager, said in an interview with All3DP. “They could run that test method as well.”

How Were the Standards Determined? How Are 3D Printers Tested?

UL Standards has three branches that run the gamut in terms of developing standards and testing products within them, commissioning studies with its internal UL Research Institutes – reports like “The Impact of 3D Printing on Indoor Air Quality in Educational Settings“, which provides analysis on how emissions from a 3D printer behave in non-industrial environments – while UL Standards and Engagement writes standards like UL 2904, and finally UL Solutions, to which Laughlin’s team belongs, handles the business of testing and certifying products under the standards with the Greenguard product family label.

The standards and engagement team uses what it calls “technical committees” – a group of experts in the subject matter – to consider existing research then develop, establish, and maintain proposed standards. The current version of UL 2904, for example, is actually the second iteration of the certification that was first introduced in 2017 and updated in 2023.

Anyone can submit a proposal for consideration, but it has to be “fully developed”, which UL describes in good detail in a free “standards development process” tutorial. The gist is a detailed proposal with documentation and contacts to back up the need for a standard and help it get off the ground. A draft is written and validated in something of a democratic process among the technical committee.

For UL 2904, maximum emission allowances are determined using accepted thresholds from official public health bodies and a mathematical ventilation model to determine emission rates, resulting in accepted levels in target environments.

The standard’s target environment is a 30.6 m3 office (12 x 10 x 9 ft). Maximum UFP allowance is set to 20 billion particles per gram of feedstock, and 300 billion particles per hour.

VOCs are a little more complicated, given the different acceptable levels for “non-cancer chronic reference exposure levels” of each compound based on thresholds from the California Department of Public Health (and those for similar VOC categories and institutional thresholds), and are outlined in a large table in the standard. For benzene, the acceptable level is 0.0312 mg per hour; for formaldehyde, it’s 0.187 mg per hour.

As for the UL 2904 Greenguard certification and validating whether a machine and its materials “meets criteria”, UL puts the subject 3D printer in a six cubic meter specialized stainless steel chamber. “It’s designed not to have any places where chemicals will stick or where it will create its own extra chemical contamination for the product,” Laughlin said. Then, after being left in the chamber overnight, emissions are collected over a 4-hour print. Particle emissions are collected via a variety of aerosol sizing instruments while VOCs are collected by a sorbent medium (think sponge) through which air is passed at a known rate. Collected emissions are then measured, mostly via gas chromatography–mass spectrometry but high-performance liquid chromatography is used for low molecular weight aldehydes like formaldehyde or acetaldehyde. The data is graphed, and UL can compare the device emissions to its standard.

What Does That Mean for Users?

The biggest takeaway here is that the standard isn’t as vague as it might appear at first glance. Though UL’s Greenguard certificates simply state that a product “meets criteria”, both the development of UL 2904 and Greenguard certification process employ rigorous methodologies, with target criteria that are backed by recommendations from trusted authorities.

Still, “meets criteria” doesn’t tell consumers what, exactly, that certification should mean for how they treat 3D printing at home or in the office. UL Standards stops shy of saying certified products “are safe”, and clarified to All3DP that the products simply “meet safety standards.” Scientists everywhere might rejoice at the acknowledgment that research and safety standards evolve over time, but that (perhaps legally necessary) particularity can make the takeaway a little confusing to concerned consumers. Potato, potahto. Meeting those trusted body standards suggests that, based on what we know right now, certified printers are safe. And in realistic conditions, too: my own (somewhat claustrophobic) home office comes pretty close to the 30.6 m3 testing conditions.

Prusa Research is less apprehensive in its language, with Průša telling All3DP its certified products are safe in enclosed spaces, but notes proper ventilation is still a best practice.

“We’ve been very careful about the additives in our filaments,” Průša said. “If our PLA hadn’t passed, it would red flag open frame 3D printers.”

We’d love to see more of the massive third-party materials market participate in UL 2904 certifications, even if they choose not to use UL Standards’ Greenguard product to do it. For Prusa, the company has sought certification for products with other risk factors; at the same time as Průša shared the new Greenguard certification, he also shared some details about testing its carbon fiber-filled PA11CF material.

“Carbon fibers can sometimes get stuck on the skin and remain there even after several hand washes,” Průša said. “we had thorough laboratory tests conducted by the National Institute of Public Health before we first introduced these materials into production… TLDR – our Prusament filaments with carbon fibers and prints made of them are safe.”

So, if you just want to know whether it’s relatively safe to print with your Greenguard-certified Prusa MK4 or MK4S in an enclosed environment, it seems like yes. But if you really want to understand UFPs, VOCs, and their implications, all this is just the tipping point. There’s a fair amount of research out there these days, much of it from UL, and plenty of accessible things you can do to combat 3D printer emissions.

If you want a better understanding of how UFPs and VOCs behave in enclosed environments, UL Standards’ own research is a good place to start: check out the recent multi-year study, “The Impact of 3D Printing on Indoor Air Quality in Educational Settings“, published in August 2024 that followed up on previous work measuring air quality in a university maker space.

There’s a wealth of less formal but often still helpful information around, like Made with Layers’ (Thomas Sanladerer) recent YouTube videos where he investigates 3D printer emissions and safety solutions in his studio, and guides viewers in making their own air quality measurement device.

If you want to go a little further, UL Standards has official safety guidelines for using 3D printers, specifically intended for labs in higher education facilities. The guidelines go beyond emissions, which is good to get you thinking about how you interact with your micro-plastic melters.

License: The text of "Prusa Has Safety Certified the MK4S; What Does That Mean for You?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.