When Prusa Research launched its new “industrial-lite” FDM printer, Prusa Pro NT90, this past Summer, it teased its upcoming development of one of the toughest engineering-grade filaments available. Now, it is officially launching Prusament PEI 1010 by Prusa Polymers, available today at about $139.00 per half kilo.

Although you may know PEI as build plate coating, this type of PEI (polyetherimide) is different. It’s commonly used in aerospace applications, medical devices, and some automotive uses because it can withstand extreme heat, mechanical stress, and the effects of chemicals and gamma radiation.

PEI, commonly known as Ultem, is a high-performance engineering thermoplastic that produces printed parts that have tensile strength similar to aluminum. In fact, 3D printed PEI parts can be used to replace metal in some aviation and space applications.

Not Printable on Original Prusa Printers

The new Prusament PEI 1010 is not a “plug and print” material, the company says, and is not suitable for the Original Prusa printers because it requires a hot end capable of reaching and maintaining a temperature of 410 °C, a consistent 150 °C print bed, and at least 90 °C for the chamber. It is ideal for the Prusa Pro HT90 or similar industrial FDM 3D printers, like a 3DGence Industry F421 ($65,000) or an Aon3D Hylo ($100,000+).

Prusa Research also cautions that the material is designed for pro users.

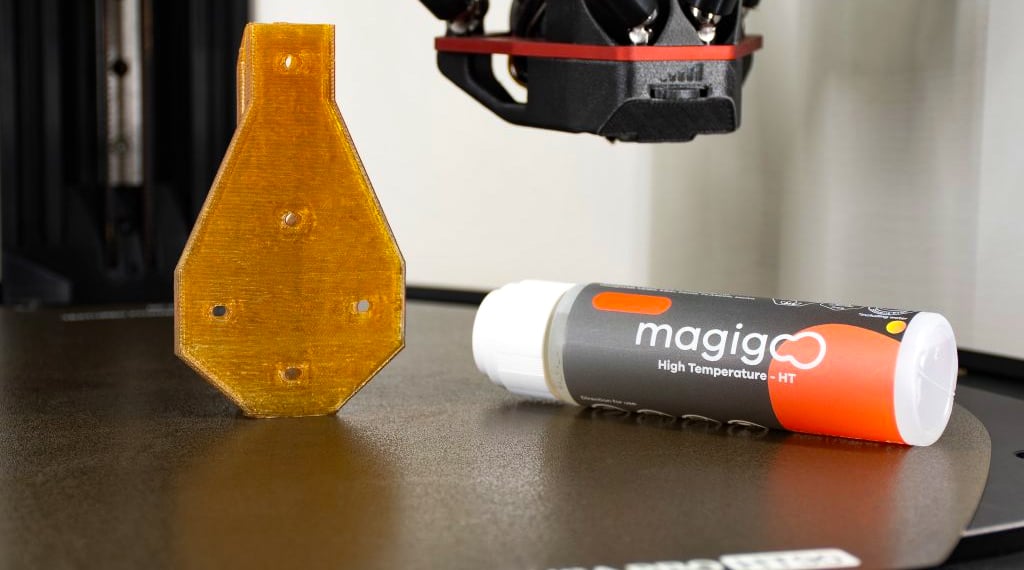

“We did our best to make the filament as easy to print as possible but still, working with such filaments requires some experience and knowledge,” the company says. Prusament PEI 1010 tends to “warp a lot during printing”, which is something to keep in mind when designing and slicing models.

PEI filament is also very hygroscopic, meaning it absorbs moisture from the environment extremely fast and is difficult to undo, the company says. It has to be kept perfectly dry (a professional dry box and dryer are necessary).

Prusa created a guide to printing with PEI 1010 that details all of the pre-printing, printing, and post-processing required to get the most out of your parts.

The material is manufactured in Prusa’s Prague factory, like most all of its filament, to specific standards from raw materials. Prusa also developed a new high-temperature-resistant spool for the material so it could withstand the required drying. The spool is made out of carbon-fiber nylon waste from the company’s other extrusion line.

“Using this material significantly improved the spool’s temperature resistance and further decreased the waste produced during the Prusament manufacturing process,” the company says. “We also had to add screws that hold the spool in one piece during the drying. This added a few grams to the empty spool’s weight, which is now 203 g.”

Although PEI by nature is a flame-resistant Prusament PEI 1010 doesn’t yet have the UL certification. PEI 1010 in comparison to other grades of PEI has a higher flexibility and transparency, thus the luminescent gold effect.

Who Will Use PEI?

Prusa see the space and auto industry as big users of PEI material, especially for lightweighting battery-powered vehicles. Prusament PEI 1010 Natural was approved for inclusion into the International Material Data System (IMDS), which is what automakers use to manage information about materials used in automotive components and their compliance with international regulatory standards.

PEI 1010 can withstand a broad range of chemicals and can go through a sterilization process in an autoclave, electron beam, ethylene oxide, and gamma radiation. The combination of these properties makes it suitable for scientific and medical applications.

Prusament PEI 1010 by Prusa Polymers: Mechanical properties of 3D printed testing specimens

License: The text of "Prusa Launches PEI Filament for Extreme Conditions" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.