Prusa Research has just released a firmware update for the Prusa MK3/S and MK2.5/S, which founder Josef Prusa called an “incredible amount of work.”

Read on for the most interesting parts of this 3.9.0 firmware update as well as news on the Prusa XL 3D printer, and a new print-on-demand feature on the company’s website.

Prusa XL

Before we take a closer look at what this newest firmware update has in store, Prusa provided a brief update in a blog post on the status of the Prusa XL 3D printer. Although it is continuing the development of the XL, even during the current Covid-19 situation, the company founder said he does not want to “share any estimations, because that could lead to false hopes and the development process of the printer is not yet finished.”

However, the good news is that the team has “more time to tweak and optimize the entire machine,” added Prusa, and “some of the features might even trickle down to the MK3S.”

Firmware 3.9.0 Updates

Prusa XL updates aside; you can now download the free firmware update from the Prusa website. If you’re interested in the nitty-gritty details about particular features and changes, check the complete changelog on Github. We’ve compiled the most important updates for you below.

- Linear Advance 1.5 — Probably the most significant update is the implementation of linear advance 1.5, a technology that predicts the pressure build-up in the extruder when printing at higher speeds. It will use that prediction to decrease the amount of filament extruded just before stopping or decelerating and thereby preventing blobs or artifacts at sharp corners of the object. Linear advance 1.5 also allows for easier implementation, resulting in a lower CPU workload.

- Screen brightness adjustment — If you have an Original Prusa i3 MK3S 3D printer that was manufactured in the second half of 2019 or later, its LCD screen allows brightness adjustments. If your printer model does not support this functionality, it won’t be displayed on the menu.

- Filament sensor status detection — Some work was put into this feature to improve the recognition of the filament sensor status. The printer is continuously measuring the voltage (you can monitor it in LCD Menu – Support – Voltages) and based on the value, it recognizes three states: inserted filament, no filament, and disconnected sensor, but also whether the filament sensor gets disconnected or damaged (the voltage will change from +4.6V to +5V).

- MMU2S selector blade activated — The MMU2S unit contains a small blade for cutting filament ends. Up until now, it wasn’t active, but now it is. Make sure you have FW 3.9.0 in your printer and FW 1.0.6 in the MMU2S unit.

- Improved power panic — The MK3 had the power panic feature from the beginning. However, everything can be improved. Now, the power panic feature is more stable, and it even uses the last bits of power to move the nozzle from the object. However, it’s unable to shut down the MMU2 unit quickly enough, so it drains all power before anything else.

Tweaks and fixes

There are many other tweaks and fixes in firmware 3.9.0. Some of them are briefly mentioned below.

- MK350 (micro-stepping) enabled for all axes

- MK3 filament sensor fixes

- Heating disabled during MBL

- Automatic e-jerk conversion (required for precise PrusaSlicer print time estimations)

- Flickering statistics screen fixed

- “Unknown height” displayed for Z-axis fixed

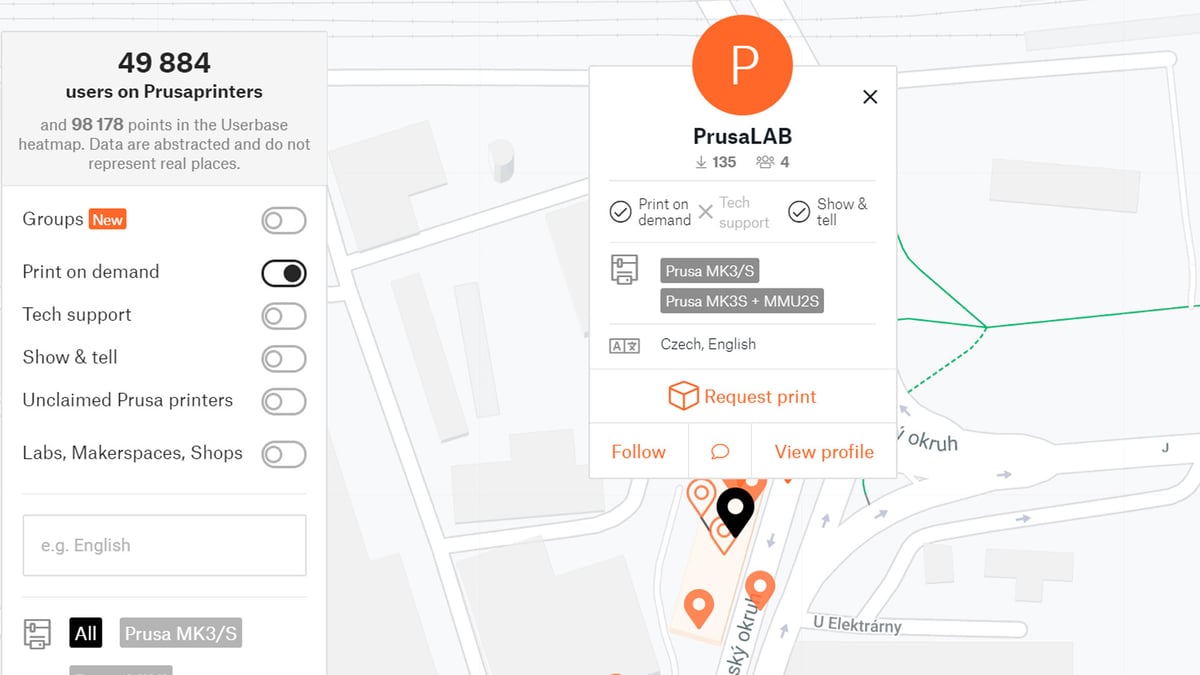

Print-on-demand

On the company’s website, a new print-on-demand function has been implemented. Users can now tick a box in their profiles, which signalizes they are ready to accept requests from other users. Vice versa, if you want to have something printed, you can open the world map and display users offering services near you. Bear in mind that this is just a basic implementation of print-on-demand – we Prusa wants to add new features and improve the overall user experience in upcoming months.

Prusa Live Stream

Josef Prusa further stated that due to the corona crisis, trade shows and fairs have been canceled. To still stay in touch with fans and customers, the company set up a live stream with the recording of the first stream already available on YouTube and plans to broadcast new episodes every two weeks. For further details, keep an eye out for announcements on social media.

(Source: Prusa Research)

License: The text of "Prusa Research Releases Firmware 3.9.0, Gives Update on Prusa XL" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.