The Prusa Research booth at this past Rapid + TCT in Detroit showcased its Prusament filament lineup in several practical assemblies, especially highlighting its PETG’s watertight potential and the translucency of its PVB after vapor smoothing.

The PETG demo was one of the booth’s more eye-catching displays, as the material was used in a closed-loop water system. The assembly consisted of two chambers and a pump, housed by cast acrylic against 3D printed PETG to create a watertight seal. Visitors had the opportunity to speak with Prusa Research representatives while scanning QR codes that detailed the assemblies’ Prusament materials: Prusament PETG (black), ASA, PC-CF, and PETG V0.

Prusa Research claims that the excellent watertightness of the assembly, which ran for the three days of the event, is due to the use of PETG Prusament. Leakage was clearly a solved problem for Prusa 3D printers — fluid element components, such as the peristaltic pumps’ cage and lobes were 3D printed in Prusa’s characteristic orange — and off-the-shelf electronics components complemented the 3D prints to complete the assembly.

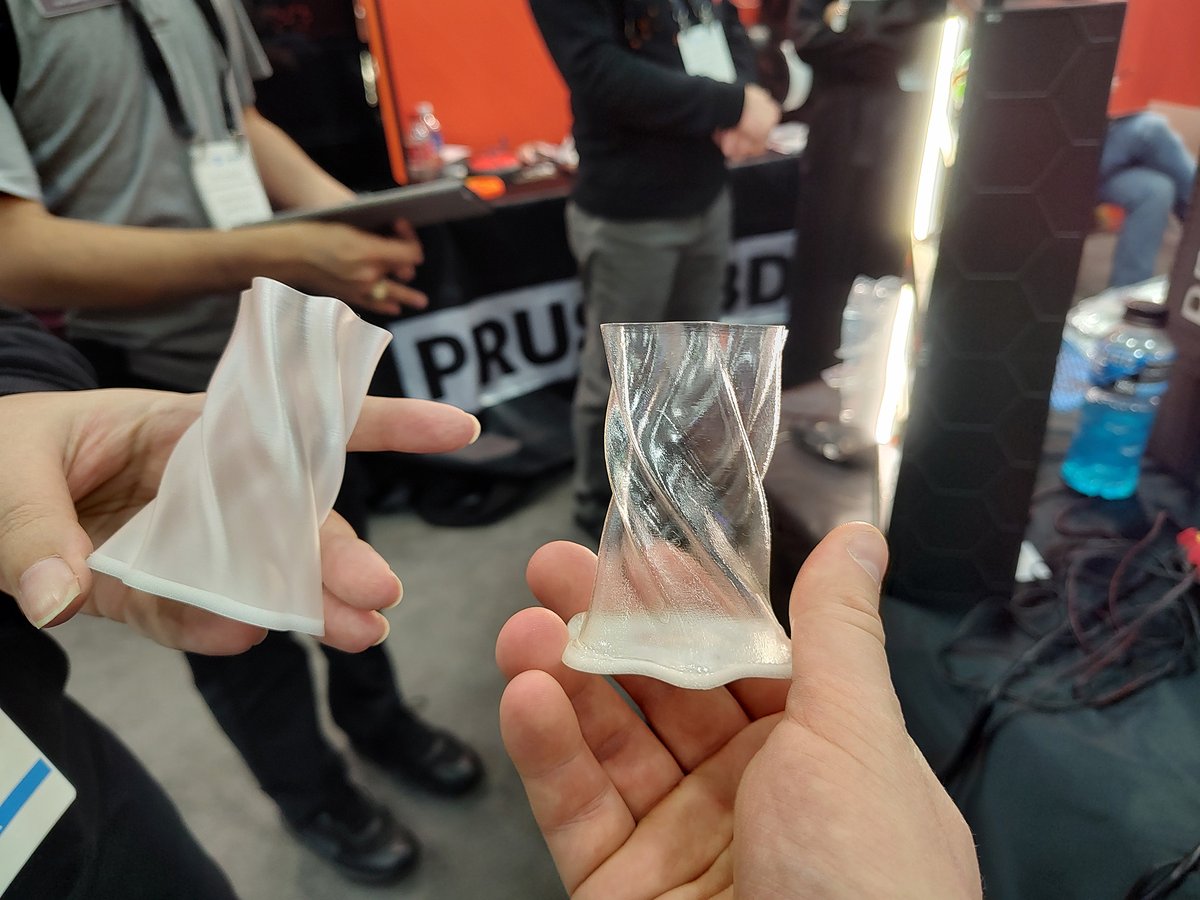

Prusa’s other various filaments were showcased in its swatch booth, which allowed visitors to feel each filament and gauge their characteristics by hand. Prusament PVB filament, demonstrated both before and after vapor smoothing with IPA, caught our eye. The result showed resin-like translucency after the smoothing process.

Read more recent news:

License: The text of "Prusa Showcased Its Filaments Functionally at Rapid + TCT" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

Stay Informed, Save Big, Make More

Stay Informed, Save Big, Make More