For what feels like an age, Prusa Research has been tantalizingly dropping hints about the new technology they’ve been working on. It’s been almost too much to bear at times, but we’ve finally had one such technology revealed, and it offers a more tangible look at what the highly anticipated Original Prusa XL will be, too.

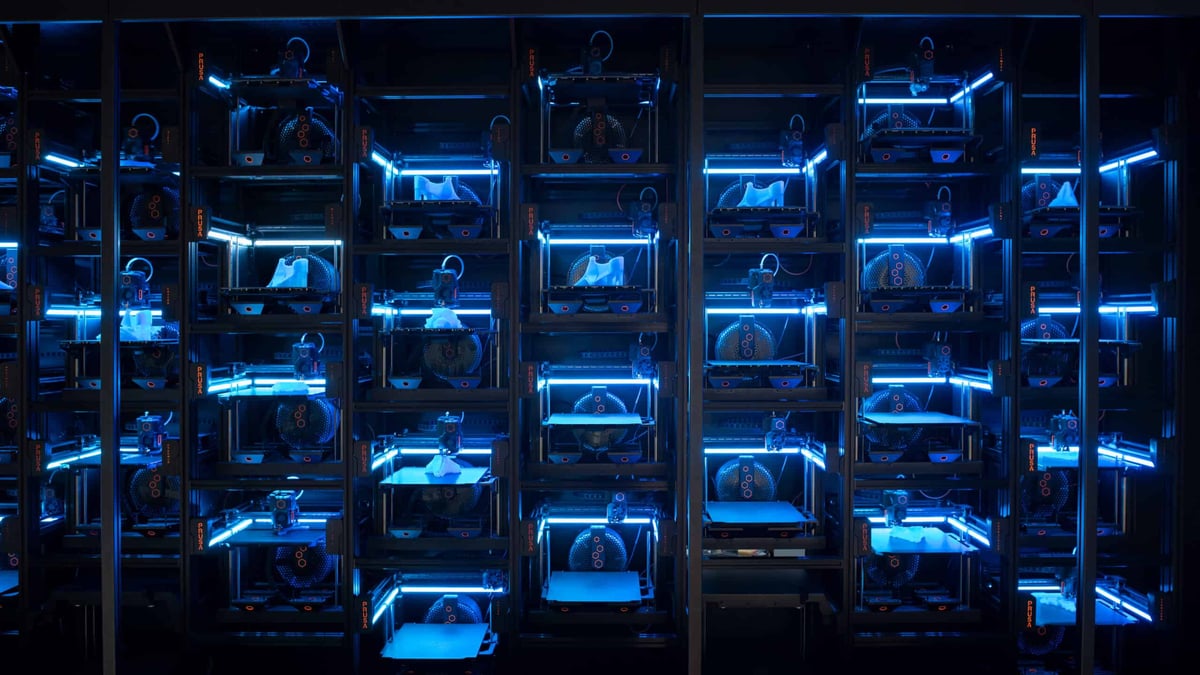

Dubai’s EXPO 2020 is underway this week, a year behind in date but still far ahead in technology. One featured piece of tech is the Prusa Pro Automated Farm System (AFS), which has the potential to be a massive step forward in mass production.

In a blog post accompanying the reveal, Prusa says the AFS uses an automatic collection and delivery system with farms of Original Prusa 3D printers. The printers are variable in number, allowing flexible farm scaling, and easily exchangeable using a server-rack-style sliding tray for easy maintenance and replacement.

When Prusa Research says automated, it really means it. The AFS ques print jobs with Prusa Connect – bearing the same name as the company’s web interface called “Prusa Connect Local” – that is able to select the best printer for new jobs on the fly. In its blog post, Prusa explains, “it finds the best machine for the job automatically (e.g., a machine that just finished printing and is not fully cooled down yet, so getting back to operating temperatures will be faster and more efficient)”.

Print sheets bearing completed parts are removed by a mechanical arm that deposits objects in a collection area. For Prusa’s demonstration that’s a simple bin, but the company says it will also have the ability to unload in ways that suit traceability pipelines.

The target price Prusa Research is suggesting for the system is shockingly affordable at ~$3,000 per printer plus servicing fees. At 34 3D printers, like the system in Dubai, that would come to about ~$102,000 before servicing. That’s already lower than some industrial 3D printing systems that often come with their own servicing structures and closed ecosystems.

This isn’t the first time an automated print farm concept has been on display. The resin 3D printer manufacturer Formlabs had an automated print farm concept they revealed in 2017 using their Form 2 SLA 3D printers and a robotic arm to move build plates with completed parts attached.

There’s been no news on the system for some time now, however, and it’s unclear if the company plans to release a product in this vein.

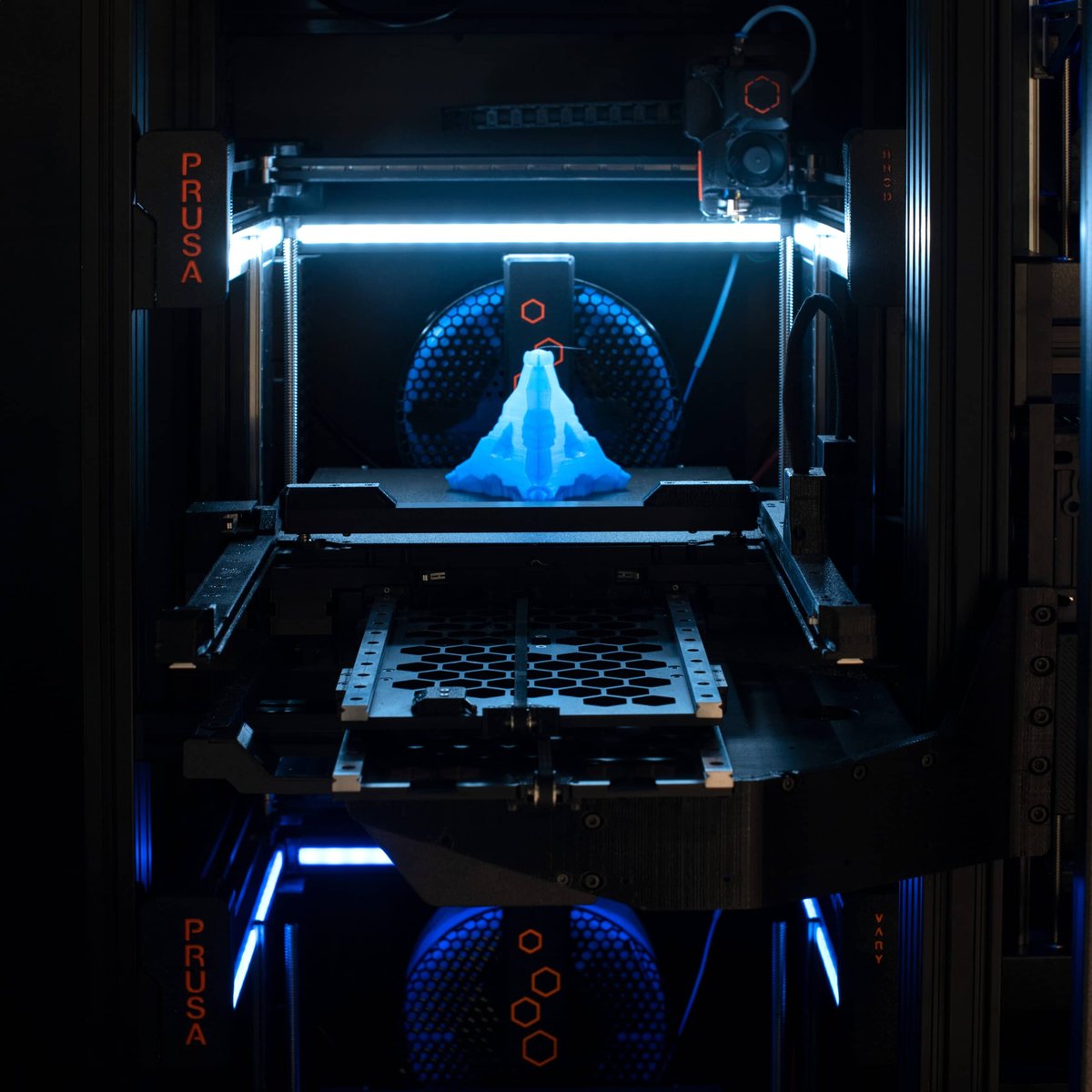

What could be exciting to many regular consumers is the peek the AFS gives them at Prusa Research’s new CoreXY technology. Prusa has been teasing for some time that their Dubai reveal will include technology “based on the Prusa XL” – an upcoming Original Prusa CoreXY 3D printer with integrated tool changing expected to cost somewhere between $1,200 and $1,500.

The printers attached to the AFS aren’t exactly like how the Prusa XL will be, the company says, “they are smaller and there are no tool-changing options yet,” but do “share certain features and technologies”.

The company is being intentionally light on the technical details ahead of the Prusa XL’s own reveal, so we don’t know much yet, but it’s exciting to get a first look at what might be the future of small-batch manufacturing and a new Original Prusa 3D printer technology at the same time.

License: The text of "Prusa Research Unveils the Prusa Pro Automated Farm System" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.