Prusa Research launched its latest 3D printer, the Prusa Core One, over a month ago. Though the OEM clearly sees the enclosed CoreXY system as direct competition with Bambu Lab’s X1C, it’s still missing a feature many see as essential: multi-material 3D printing.

This is all to plan, of course. Prusa announced just before the Core One’s launch that it expected to release a compatible version of the MMU3 in April and, at the same time, revealed that it was “exploring” another version to better integrate the system with special attention paid to form factor – sharing one prototype of a top-mounted MMU3 enclosure.

Prusa likes to tout that the MMU3 is the most material-efficient multi-material system out there (we agree!), but its current form is at odds with the space-efficient goals of the Prusa Core One. A major marketing point behind the Core One has been how little room it uses for a larger build volume than Prusa’s open-frame machines –50% less space for 30% more build volume if you include the bulky Prusa enclosure – but the MMU3 likes a wide spread.

The filament buffer, a unit between the spools and selector, is trim enough, and we hope Prusa can slot the part into the Core One’s convenient recessed sides. Right now, it looks too large, and Prusa has said the Core One MMU3 coming in April “is very close to how MMU3 works with the MK4S, down to details such as the length of the PTFE to the print head”, so we don’t expect it to mess with form factors much just yet. But maybe the buffer is an exception. Even so, the current version looks like it will see spools exposed to the elements without a homebrew dry box solution.

Overall, the current MMU3 is a far cry from the competition’s AMS: a convenient sealed box that only requires users to attach a small filament buffer and plug into a conveniently exposed port, both on the machine’s back.

But – clearly – Prusa is working on changing that. The top-mounted and fully enclosed MMU3 prototype Prusa already shared is one example. Though, it cautioned heavily that was an early exploratory prototype and not an upcoming product. But there are also hints that Prusa will make connecting the MMU3 a bit more convenient.

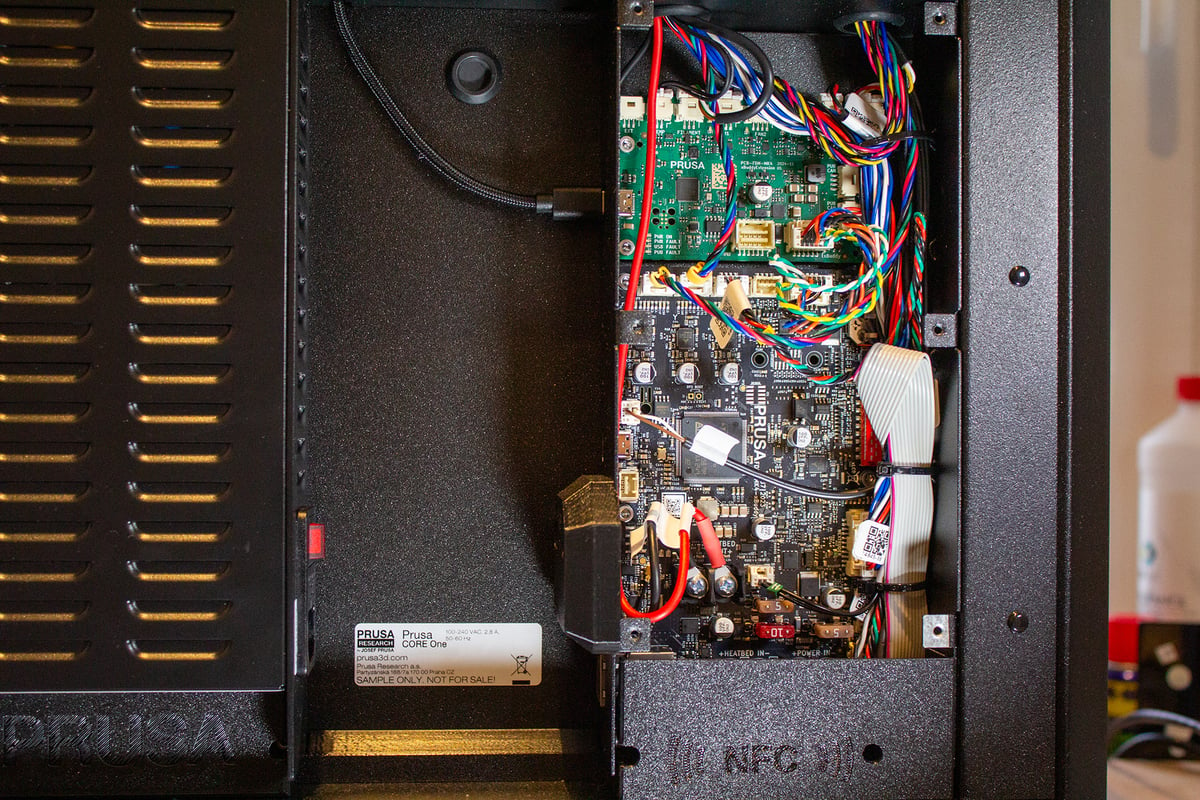

For previous Prusa 3D printers, the MMU is plugged directly to the system’s mainboard. This appears to be changing slightly for the Core One, as an update to the Prusa Firmware GitHub has noted features of the xBuddy Extension board to include an MMU port that “acts as a passthrough from the xBuddy motherboard”.

Functionally, this isn’t much different than the MMU assembly process with the MK4. The xBuddy Extension board is housed with the primary xBuddy mainboard, so you’ll still need to open the cover and plug it in, but this does create opportunities for more convenient setups if you’re inclined to move things around. Potential underscored by a parenthetical note included in that update: “we’re exploring adding MK4 [Extension board] support for DIY enclosure.”

The basic Core One MMU3 is still expected this April, alongside the Original Prusa MK4S to Prusa Core One conversion kit. We’ll likely hear more about potential alternatives then.

Read more recent Core One news:

License: The text of "Prusa’s Core One MMU3 is Expected Next Month, But Will It ‘Fit’?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

Stay Informed, Save Big, Make More

Stay Informed, Save Big, Make More