Dyze Design Inc., a prominent player in the 3D printing extrusion technology landscape, is set to introduce its latest innovation, the Pulsar™ Atom precision pellet extruder, at the 3D Print Paris exhibition on October 11, 2023. This high-performance pellet extruder marks a significant advancement within the industrial pellets 3D printing sector.

“Our customers have been eagerly anticipating the launch of this new smaller and lightweight pellet extruder, and we’re excited to bring this technology to the market. We believe it will transform the way industries approach 3D printing, slowly moving away from filament,” says Simon Duchaine, Chief Commercial Officer of Dyze. “We’re dedicated to empowering 3D printing professionals with the tools they need to excel. Pulsar™ Atom is a testament to our commitment to precision, quality and performance in industrial 3D printing.”

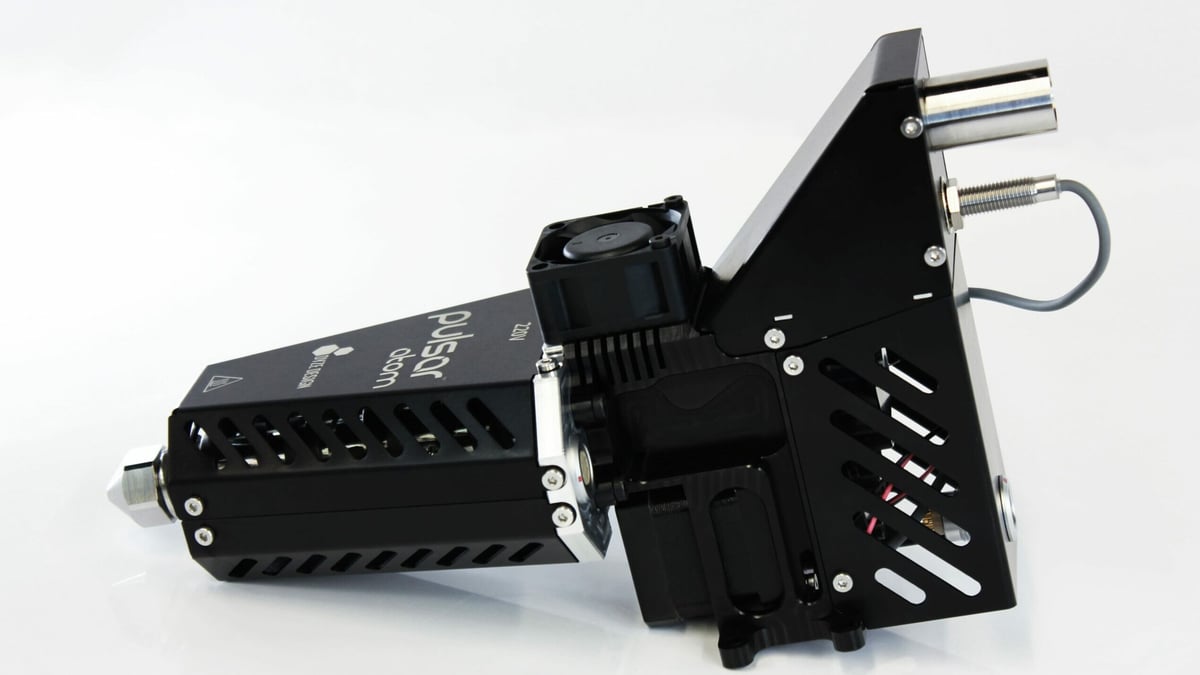

Like other Dyze Design’s extrusion systems, Pulsar™ Atom stands out for its capacity to attain temperatures up to 450 °C, expanding the possibilities for working with high-temperature and engineering materials. Moreover, its remarkable heat resistance, enduring temperatures up to 150 °C, ensures reliable performance even in demanding industrial conditions, such as heated environments. The extruder maintains a stable mass flow rate with variations of less than 5% and a compression ratio of 1.5. Specifically optimized for 3d printing, this pellet extruder guarantees consistent and reliable extrusion across a spectrum of thermoplastics.

The Power of Flow Rate

In the world of industrial 3D printing, printing time is non-negotiable. While using nozzles ranging from 0.4 mm up to 2.5 mm optimized for high-precision work, Pulsar™ Atom still delivers an impressive output flow of approximately 1 kg per hour, maximizing productivity without sacrificing quality and accuracy.

Adaptability at Its Core

Pulsar™ Atom offers an astounding 45 degrees of freedom around the nozzle, making it ideal for robotic applications and non-planar 3D printing. For those who seek a seamless printing experience, an auto material feeding system is available to supply pellets from the material source directly to the extruder.

The new printhead doesn’t compromise on any aspect of its design. It uses high-fidelity PT100 temperature sensors for precise temperature control. Despite its high-flow capabilities, it remains compact and lightweight, weighing less than 1.5 kg and standing at under 245 mm in height.

The pellet extruder seamlessly integrates with any open-source firmware and popular 3D printer controller boards such as Duet3D and BTT SKR. It is equally at home in the hands of robotic arms, ensuring versatility across various industrial applications.

Pre-Order Now

Dyze Design is now officially accepting pre-orders for Pulsar™ Atom and is planning to start order fulfillment early 2024.

To secure this cutting-edge pellet extruder, visit www.dyzedesign.com/pulsar-atom-pellet-extruder or contact their sales team at sales@dyzedesign.com.

About Dyze Design Inc.

Montréal-based company Dyze Design has been in the 3D printing industry since 2015 developing and manufacturing cutting-edge high performance, reliable, and innovative extrusion systems and 3D printer components for professional and industrial 3d printers. They are renowned for their Typhoon™ high-flow extruder, Pulsar™ pellet extruder, DyzeXtruder GT and DyzeXtruder Pro extruder line, their SENTINEL™ filament detector or Tungsten Carbide Nozzles. Today, many 3D printer brands such as Roboze, Sharebot, Blackbelt, PodoPrinter, AON3D, Trideo, 3DPlatform, Filament Innovations, and Kuka have chosen their hotends, extruders, or nozzles as OEM parts for their industrial or high-end 3D printers.