While this past year has changed the manufacturing landscape for many, the global 3D printer manufacturer Raise3D has continued to innovate and trail-blaze across the professional 3D printing field. By continuously advancing upon its most popular product offerings, Raise3D has managed to remain ahead of the curve when it comes to FDM 3D printing – and 2021 has been no exception.

As the year comes to a close, Raise3D has decisively rolled out a selection of new professional 3D printers that build upon the success of previous models. Raise3D E2CF, devised from the E2 3D printer, is a novel machine that was built to handle the oftentimes challenging process of printing with carbon fiber material. Meanwhile, the latest iterations of the flagship Pro Series, the Pro3 and Pro3 Plus, showcase how far Raise3D has come in terms of usability and intelligence.

Before we pop the champagne and put the year behind us, let’s take a look at Raise3D’s latest assortment of professional 3D printers.

Raise3D E2CF: Professional 3D Printer for Carbon Fiber Parts

Following in the footsteps of its E2 3D printer, Raise3D has emerged with a more advanced version specifically designed to print carbon fiber parts. With the new E2CF professional 3D printer, Raise3D hopes to satisfy the stringent manufacturing requirements often faced by the automotive, aerospace, and healthcare industries.

“With the release of the E2CF, Raise3D fills the market gap for a desktop-level 3D printer optimized for fiber-reinforced filaments and will make carbon-fiber 3D printing affordable and simple at last,” said Edward Feng, Raise3D’s Global CEO.

The Raise3D team has worked to ensure that the E2CF offers consistent performance and boasts state-of-the-art usability.

Raise3D Releases Carbon Fiber and Support Material

Alongside the carbon fiber 3D printer, Raise3D has also developed Industrial PA12 CF and its breakaway support material. The PA12 CF provides an exceptional strength-to-weight ratio and is engineered to work consistently with the E2CF. The high tensile and impact strength of this carbon fiber material makes it ideal for producing jigs and fixtures, engineering tooling and other industrial-grade end-use parts.

Extruder Exclusively Designed For Carbon Fiber 3D Printing

The double-gear extrusion system found in the E2CF is a key part of the printer’s compatibility with carbon fiber filament. Compared to the E2, it offers twice the feeding grip force and is built with industrial-grade components that can withstand the abrasive nature of fiber-reinforced materials. The high-durability nozzle and feeding system were enhanced in order to ensure a longer lifespan for long-term usage. In fact, with Raise3D’s Industrial PA12 CF filament, the E2CF can keep printing with the same nozzle for over 1000 hours.

A Print Perfect Environment

Another crucial component to this carbon fiber 3D printer are the two standalone dry boxes. By sealing nylon and fiber-reinforced filaments within these boxes, Raise3D E2CF is able to prevent humidity from negatively impacting the quality of the material. Since these types of materials are highly susceptible to water absorption, the standalone dry boxes were a necessary addition to this specialty machine.

What Else Does E2CF Offer?

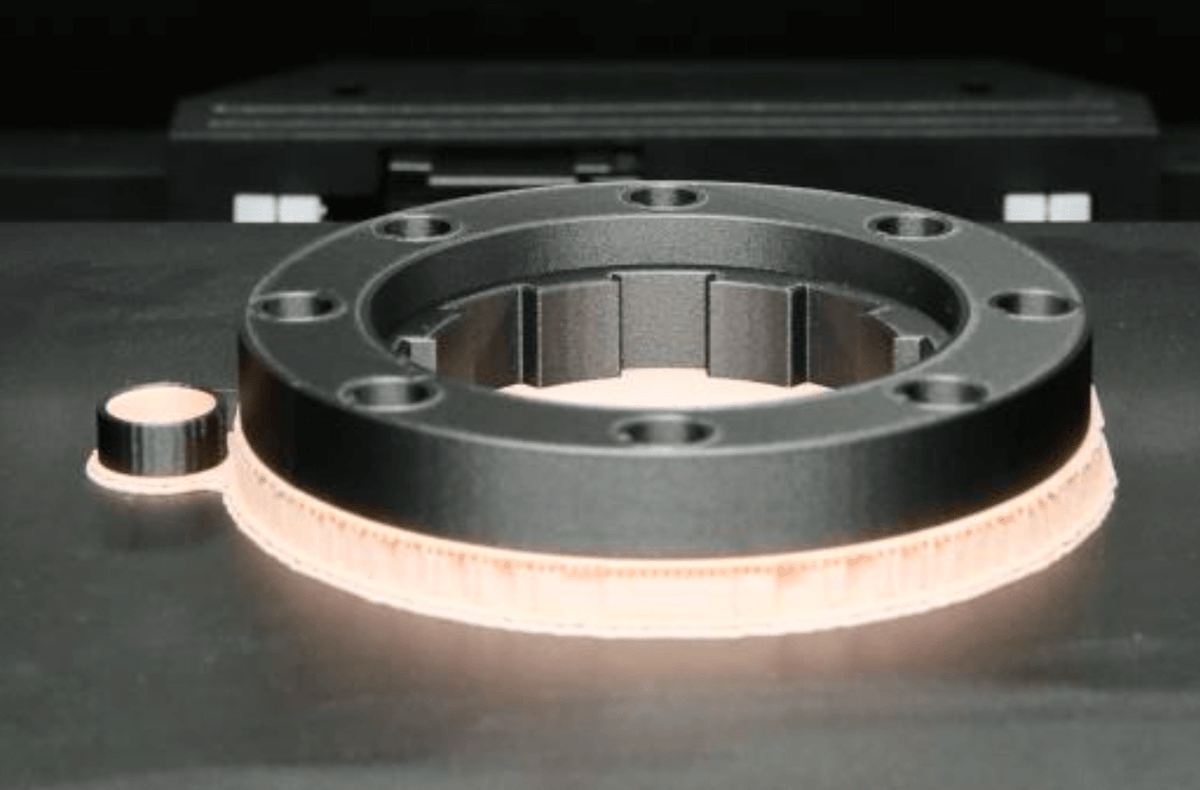

Like its predecessor, the E2CF 3D printer is stacked with features like IDEX technology, the flexible build plate, resume print function and power save mode. The new and improved auto-leveling process is tailored for fiber-reinforced filaments, accurately calibrating the nozzle height for optimal first layer adhesion and printing performance.

Raise3D Pro3 Series: Small-Batch Production Made Simple

The new carbon fiber 3D printer isn’t the only major release from Raise3D. The manufacturer has also made improvements to its flagship professional series. Specifically designed for small-batch production, the Pro3 and Pro3 Plus expands up the capabilities of its predecessor, the award-winning Pro2 Series.

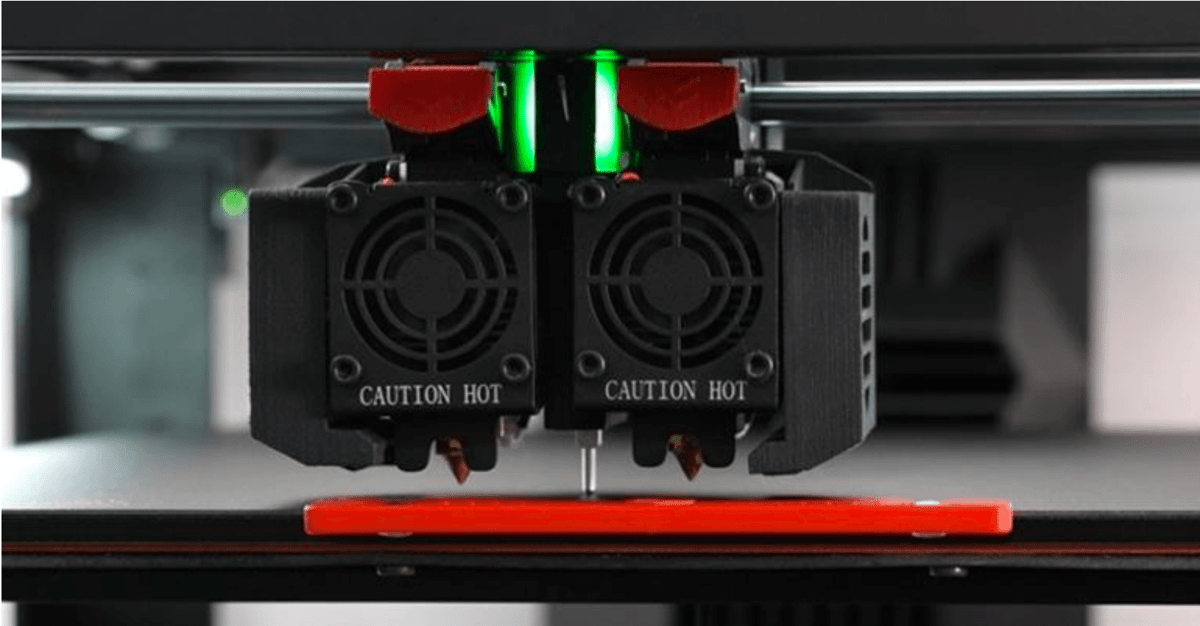

For the latest iterations of the Pro Series, Raise3D focused on improving usability and repeatability to make it better suited for various industrial applications. Both the Pro3 and Pro3 Plus boast dual-extrusion capabilities and incredible range when it comes to material compatibility. The primary difference between the two 3D printers is print volume. The Pro3 offers a 300x300x300mm build area, while the Pro3 Plus features a taller Z-axis that brings its build volume to 300x300x605mm.

Raise3D Pro3 and Pro3 Plus are priced at $5,249/ €4,749 and $7,249/ €6,249, respectively, which is surprisingly affordable considering the bevy of features you’ll find. Whether customers need to produce end-use parts or tooling, the Pro3 Series is compatible with any filament that has a printing temperature of 300℃ and below. That means users can print with a massive array of materials, including PLA, ABS, HIPS, PC, TPU, TPE, NYLON, PETG, ASA, PP, PVA, Glass Fiber Infused, Carbon Fiber Infused, and many others.

Here are some of the primary focal points that make these two machines a powerful addition to Raise3D’s growing professional fleet.

Dual Extrusion

Both the Pro3 and Pro3 Plus feature an independent modular extruder with a dual-extrusion structure. The modular design makes it easy to swap out different nozzles and utilizes a click and lock mechanism that doesn’t require tools. Each nozzle has a tracker that notes how much the nozzle has been used. Users can seamlessly replace nozzles when switching between abrasive and non-abrasive materials, or need a nozzle that enables higher print speeds.

Intelligent 3D Printing

One of the most impressive additions to the Pro3 Series is EVE, a built-in assistant system that brings usability to the next level. This assistant is designed to help customers efficiently identify and overcome issues that arise during the printing process. It also constantly analyzes the 3D printer usage to ensure the maintenance is performed at the optimal time.

Other Noteworthy Features

Various design improvements in the Pro3 Series are also worth mentioning. Raise3D managed to increase the Z-axis rod stiffness by 75%, leading to more stable performance. The extruders are connected to the 3D printer base with a lightweight cable equipped with a digital temperature measurement sensor.

Additional usability-focused features include an easy-to-use auto-leveling, HD camera for print monitoring, a flexible build plate, and automatic detection, which pauses a print whenever the door is opened. Like the E2CF, the Pro3 Series also has power recovery in the event that a print is disrupted by loss of power. Raise3D’s proprietary software ecosystem keeps the entire process in-house, from slicing via ideaMaker to managing the process with RaiseCloud.

The Air Flow Manager keeps users safe from potentially hazardous and unpleasant fumes. Equipped with a HEPA air filter, this feature maintains a consistent print chamber temperature, while also filtering and cleaning the air inside of the chamber.

For those interested in the Pro3 and Pro3 Plus, you can gather more information on Raise3D’s website or contact sales@raise3d.com.

As the year comes to a close, Raise3D has continued to solidify its standing in the professional 3D printing market. Following the release of the E2CF and Pro3 Series, we can only imagine what the manufacturer has in store for 2022.