As the fight against plastic pollution rages on, the need to find environmentally friendly 3D printing materials has become a topic of grave importance.

Researchers from the prestigious Oak Ridge National Laboratory (ORNL) have come up with a unique way of dealing with this problem. In a new study published in Applied Materials Today, the research team recently outlined a patent-pending process for developing a 3D printing material from a plant-based material called lignin.

Lignin is an organic polymer which is found in the walls of plant cells, and is also a byproduct of producing biofuels. However, it could someday become a viable and sustainable replacement for environmentally detrimental petroleum-based plastic composites.

The trouble that the researchers first faced with lignin-based composites is that the material is generally difficult to process. This means that casting and compression molding are currently the best-suited techniques for processing the organic polymer.

Eventually, the researchers decided that if they wanted to turn lignin into an alternative to plastic, they needed to find a more practical processing method. So, they decided to shift their focus onto FDM 3D printing, using the technology to produce scalable applications with the lignin-based material.

Creating a 3D Printable Lignin Composite

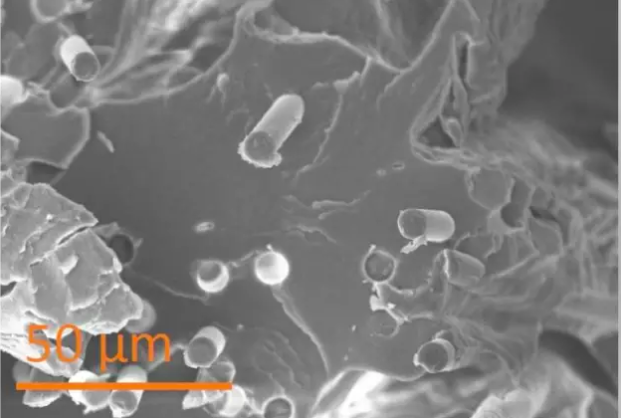

In order to create a 3D printable lignin composite, the researchers combined Organosolv hardwood lignin with other materials. On its own, lignin material often results in parts that have a brittle structure. To overcome this, the researchers added ABS, acrylonitrile-butadiene rubber (NBR41) to increase the tensile strength, and carbon fiber to make the composite stronger and easier to print.

By combining these materials, it was possible for the researchers to form a 3D printing filament for FDM technology. With this, they were able to use a LulzBot TAZ 6 3D printer to produce a design with the lignin-based material.

The researchers found that their filament has a tensile Young’s modulus that is mechanically similar to ABS, allowing them to achieve their ultimate goal of creating a composite material that is highly useful and practical.

In their study, the researchers note:

“The lignin-based composites exhibited equivalent or even better mechanical performance in comparison to regular petroleum-based thermoplastics… The combination of ABS, NBR41, and lignin revealed a promising route to utilize high loading of lignin as a sustainable feedstock for additive manufacturing.”

You can learn more about the research by reading their work published in the journal Applied Materials Today.

Source: Engineering.com

License: The text of "Researchers Develop 3D Printable Lignin Composites to Replace Petroleum-Based Plastics" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.