3D printing thermoplastics is now so advanced that it’s possible to buy a printer for your home and create parts straightaway with very little experience necessary. However, this is not the case for metals.

Currently, there are many different ways in which you can 3D print metal. However, none of them are simple or affordable. Most processes are expensive, require high temperatures and can result in material waste.

Jan Schroers, Professor of Mechanical Engineering and Materials Science at Yale University and Desktop Metal, Inc., in Burlington, Massachusetts, USA believes this is because it’s more difficult to extrude a metal.

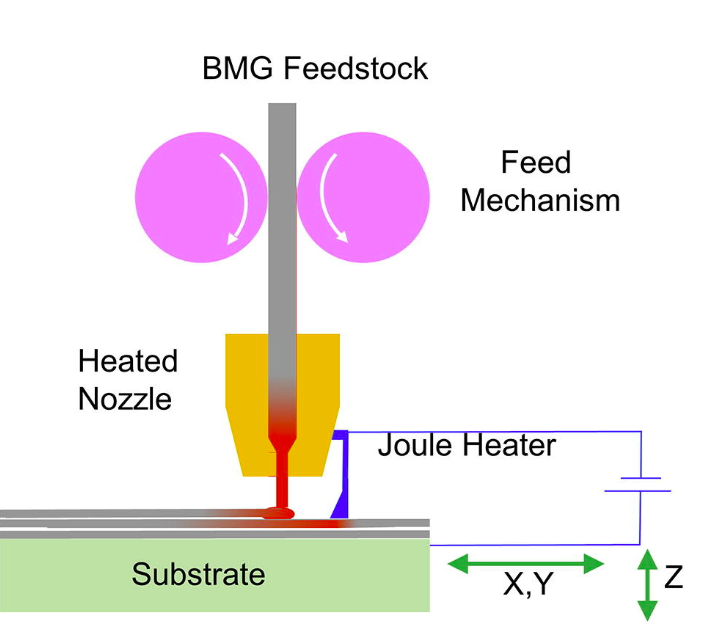

But, Schroers and colleagues think they’re onto a simpler way of additively manufacturing metal using bulk metallic glasses (BMGs). These can be continuously softened when heated and have a “super-cooled liquid region in their thermodynamic profile”.

“We have shown theoretically in this work that we can use a range of other bulk metallic glasses and are working on making the process more practical- and commercially-usable to make 3D printing of metals as easy and practical as the 3D printing of thermoplastics,” said Schroers.

Simplifying the Process of 3D Printing Metal

So far, Schroers has shown that it’s possible to 3D print BMGs to create metal components which are of high-strength and solid. The conditions used to create the parts were similar to those used in thermoplastic 3D printing.

But, the researchers used an extrusion temperate of 460 degrees Celsius (860 degrees Fahrenheit) and a force of 10 to 1,000 Newtons. The softened fibers were then pushed through a 0.5mm diameter nozzle.

However, that’s not the end of the process. Next, the fibers were extruded into a 400°C stainless steel mesh. Crystallization takes place at least one day later and finally, to create the final object, a robotically controlled extrusion takes place.

The resulting prints are strong and have elastic limits, high corrosion resistance, and high fracture toughness. The process isn’t quite as simple as 3D printing using a desktop printer but more similar than other methods of 3D printing metals. This is an impressive development.

The properties of BMGs are extremely unique amongst metals are what make it possible. For their work, the BMG used by the team is made from: “zirconium, titanium, copper, nickel, and beryllium, with alloy formula: Zr44Ti11Cu10Ni10Be25”.

However, Schroers explains: “In order to widely use BMG 3D printing, practical BMG feedstock available for a broad range of BMGs has to be made available. To use the fused filament fabrication commercially, layer-to-layer bonding has to be more reliable and consistent.”

We’ll keep you up to speed on this interesting development.

Source: Science Daily

License: The text of "Researchers Use Bulk Metallic Glasses to Simplify Metal 3D Printing Process" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.