3D printer makers routinely upgrade and update their best-selling machines to eke out higher levels of performance, but the overhaul Roboze did to its popular Argo 500, first released in 2017, is at a new level.

Roboze says the new Argo 500 “Hyperspeed” version significantly reduces printing time while enhancing accuracy and reliability. There’s also lower maintenance, reduced material waste, and enhanced workflow efficiency, the company says.

Let’s take a closer look.

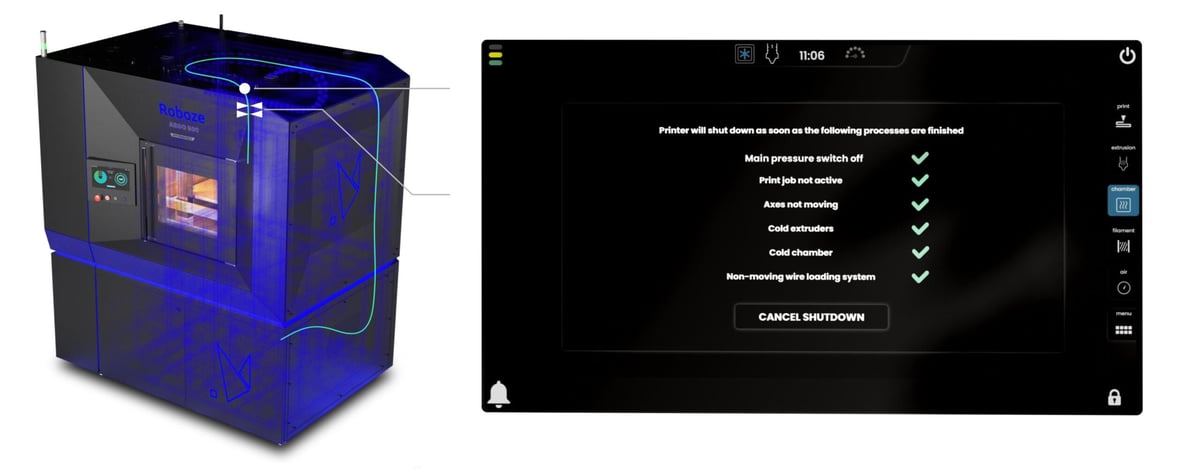

First, dont’ think of this as an upgrade; it’s essentially a new machine. Not only is there a lot of new software and firmware, but there’s also new hardware and other patent-pending elements thrown in. It replaces the existing Argo 500.

Comparing the Hyperspeed edition to the older version reveals a doubling of the maximum printing speed to 120 mm/sec from 60 mm/sec. This translates into a 25% faster print time using a single extruder and up to 62% faster print time using dual extruders. As with almost all 3D printers, high speed and high resolution are mutually exclusive, so the Hyperspeed print profile is aimed at delivering faster prototypes. Roboze still offers its Ultra Quality, Quality Speed, and Productivity profiles on this new machine.

Hardware optimizations enhance the machine’s movements, reducing extrusion change time, and accelerating production rates, Roboze says. The new extruder feeding system with dual pinch is another element enabling high printing speeds. And there are sensors for clog detection and material flow control.

Faster prints ultimately save you money in the form of time, but the new Argo 500 Hyperspeed also uses 10% less compressed air, reduces filament waste (purged filament) by 37%, and the machine’s gear system is expected to last 1,000 hours which is 300% longer than the previous version of the Argo 500.

The Argo 500 Hyperspeed features a high-temperature build enclosure and nozzles to handle a wide range of technical polymers, such as PEEK and carbon-fiber nylon. The hot build chamber is designed to reduce the thermal shock of the material it is extruding out of its super-heated nozzles and to cool it down more slowly in order to reduce mechanical stress, the company says.

As with all Roboze machines, there are no rubber belts typically used in the sector and instead there’s a patented movement system with gears. Roboze says its precision and accuracy align with the typical kinematics of industrial machine tools.

Argo 500 Hyperspeed Tech Specs and Price

- Technology: FDM (filament)

- Build Volume: 500 x 500 x 500 mm

- Accuracy: (XY) 10 µm, (Z) 25 µm

- Nozzle sizes: 0.4, 0.6, 0.8 mm

- Max. Print Speed: 120 mm/sec

- Materials: PEEK, PEKK, carbon fiber PA, PP, Ultra PLA, Ultem, +

The Argo 500 Hyperspeed is accessible under a subscription plan, rather than buying the machine outright. Depending on your level of services, updates, and customization, the annual price will vary.

_______________

Never Miss Any News:

License: The text of "Roboze’s New Hyperspeed Industrial FDM Now 62% Faster Than Before" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.