Scantech, a global 3D measurement company that specializes in the development, manufacturing, and sales of 3D scanners, has officially launched an all-new automated 3D measurement station AM-DESK for efficient on-site batch measurements.

Engineered with intelligent systems and software, the measurement station aims to reduce the workload of measurements and improve efficiency. The ease of use is significantly improved due to its compact size, small footprint, and easy installation.

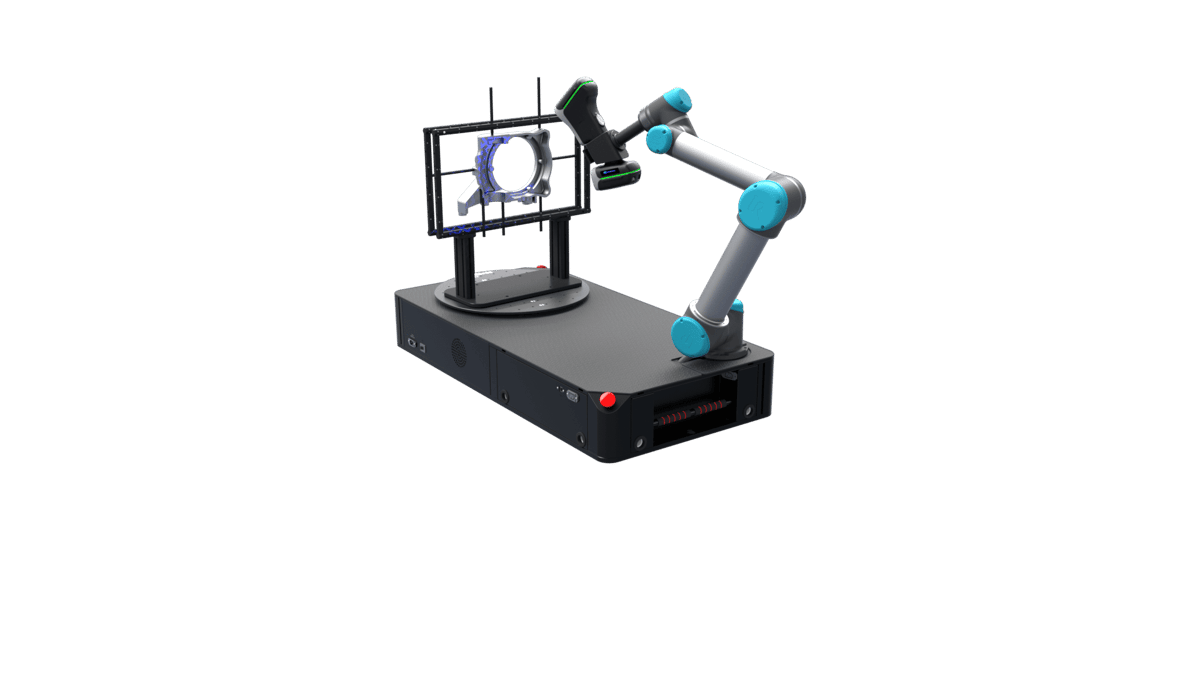

Automated 3D Measurement Station

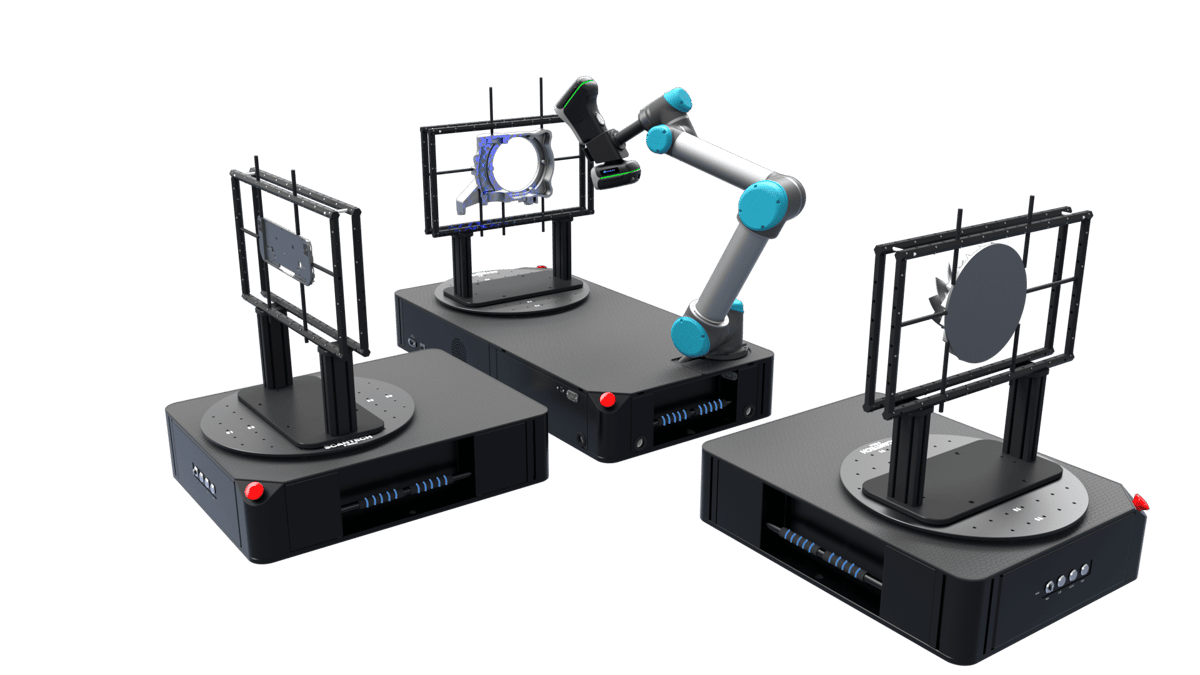

AM-DESK can be paired with different collaborative robots and Scantech’s entire fleet of 3D scanners to quickly and automatically measure numerous parts. It’s well-suited for on-site inspections on shop floors, in labs, and under harsh conditions, ensuring continuous 3D measurement with high precision in nearly any environment.

The station comes with powerful and easy-to-use 3D software FlexScan, which has a simple user interface that allows for smooth human-machine interaction. The software has multiple communication methods to support the functioning of various collaborative robots and enables automated measurement with multi-positioners in different scenarios.

Scantech is renowned for its automated 3D measurement systems, such as the AutoScan-K and AutoScan-T, which provide non-destructive inspection using machine vision technology. While ensuring extra-high accuracy, they can effectively carry out batch scanning and inspection without interruption.

AM-DESK, boasting the same advantages of these two systems, takes the automated industrial measurement to the next level by offering more robust performance in a compact size.

Quick Installation

With a weight of only 75 kg, the automated measuring station AM-DESK is portable and can be deployed with maximum flexibility. It can be placed directly on desks and mechanical platforms without extra effort. Therefore, it reduces the footprint that is typically required with a piece of measurement equipment.

Robust Performance

AM-DESK’s rapid data capturing and processing power lends itself to the device’s outstanding performance. The station enables non-contact and full-field inspections of parts under 100 kilograms. By measuring large quantities of parts, batches can be smoothly integrated into automated quality control processes for mass production.

With automatic calibration when operating in an unstable environment, users don’t need to constantly monitor the process. It can automatically calibrate its sensor after a scanning session or even when the environmental conditions change, consistently ensuring uninterruptible measurements.

Once the measurements are completed, the station can generate inspection reports automatically by comparing actual 3D coordinates and CAD data. It allows manufacturers to detect quality issues faster and achieve shorter downtime.

Easy Programming

Engineered with a PLC and servo-mechanists system, the measurement station can successfully achieve programmable and automated measurement when paired with multiple collaborative robots. At the click of a button, it can conduct complex measurement tasks via pre-planned measuring paths. The sensor mounted on the station moves to numerous pre-programmed positions according to the directions of the operator.

Integrated automatic teaching allows the user to operate the station without specific robot programming skills. Engineers and operators with different levels of expertise can use AM-DESK with ease.

Easy Operation

AM-DESK measurement station is a turnkey solution that is free from rigid setup, and doesn’t require a high-degree of know-how to use it. Users can plan measurement sequences and execute them automatically and efficiently.

The AM-DESK is perfect for measuring components with various geometries, finishes and materials, including small-scale plastics, as well as casting and stamping parts. It is reliable and powerful enough to conduct various types of measurements and supports versatile functions such as color maps, GD&T analysis, and dimensional measurements.

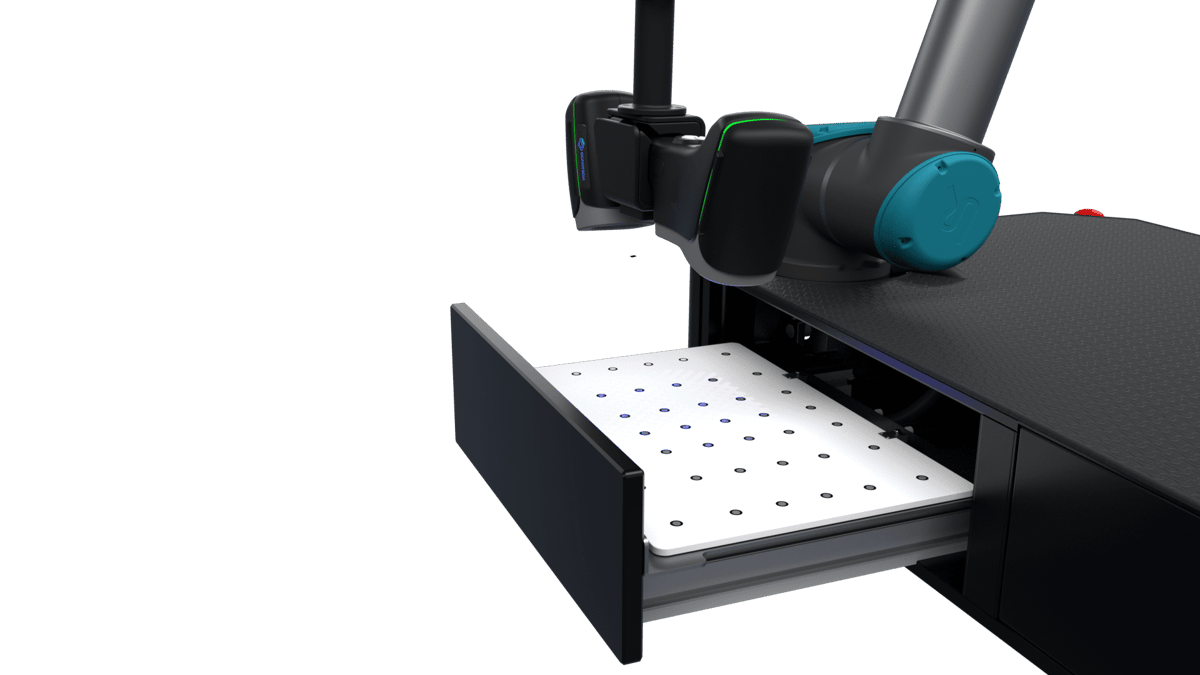

Diverse Accessories

The measurement system is compatible with different robots and the entire fleet of Scantech’s 3D scanners, from the composite 3D scanner KSCAN-Magic to the compact handheld 3D scanner SIMSCAN. The industrial robot can work in unison with positioners to expand the robot’s capabilities.

The support trays for the positioner come in different sizes, including small, medium, large, and flexible tooling. With this widespread flexibility, the different sizes and types of workpieces can be mounted onto the positioner’s tooling. The robot on the station can automatically change different measuring paths and inspect parts among other positions.

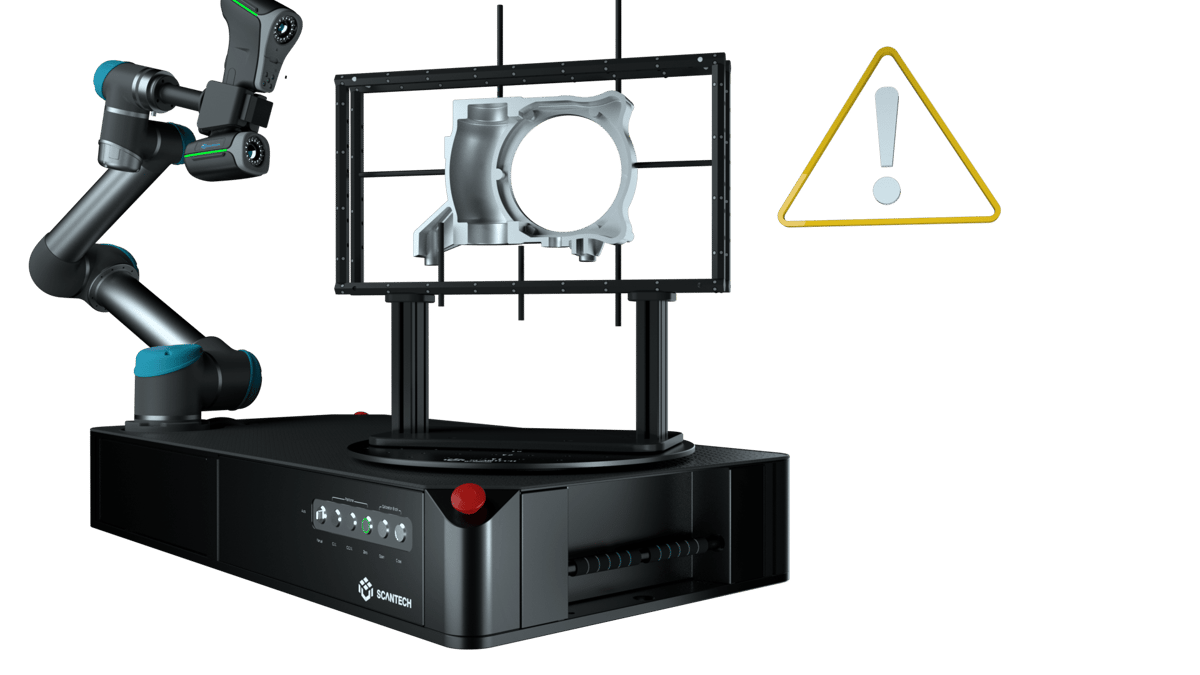

Safety Guard

The sophisticated measurement station has been designed with numerous safety features that keep the operating process safe and user-friendly. The safety measures include serial arrangement for emergency stop, a buzzer to indicate potential dangers with lights and sounds, and controllable force distance with servo-mechanists to ensure safe operations.

All robot movements are required to undergo a safety check before being performed. When an unexpected behavior or accident occurs, operators can stop the robot by pressing an emergency stop button. The station can be stopped quickly to prevent machine hazards from happening.

About Scantech

Scantech specializes in the development, manufacture, and sales of 3D scanners. Its in-house developed products range from handheld laser 3D scanners, color 3D scanners to automated 3D scanning solutions, all of which are granted intellectual property rights.