Scantech, a high-tech company that specializes in developing, manufacturing, and sales of high-tech 3D scanners, has just released its latest iteration of the TrackScan-P, a target-free optical 3D measurement system. TrackScan-P 550 is a significant advancement for the product line, featuring increased laser lines with enhanced scanning efficiency, upgraded high-resolution cameras and advanced edge inspection. The new offering provides users with enhanced functionality to enable highly efficient and accurate 3D scanning.

“We have devoted numerous efforts in designing our optical tracking 3D scanner TrackScan-P. We are confident that our customers can get high-precision measurement results efficiently. It is an industry-leading industrial 3D scanner with robust performances.” Stated Tracy Zhu, product manager at Scantech.

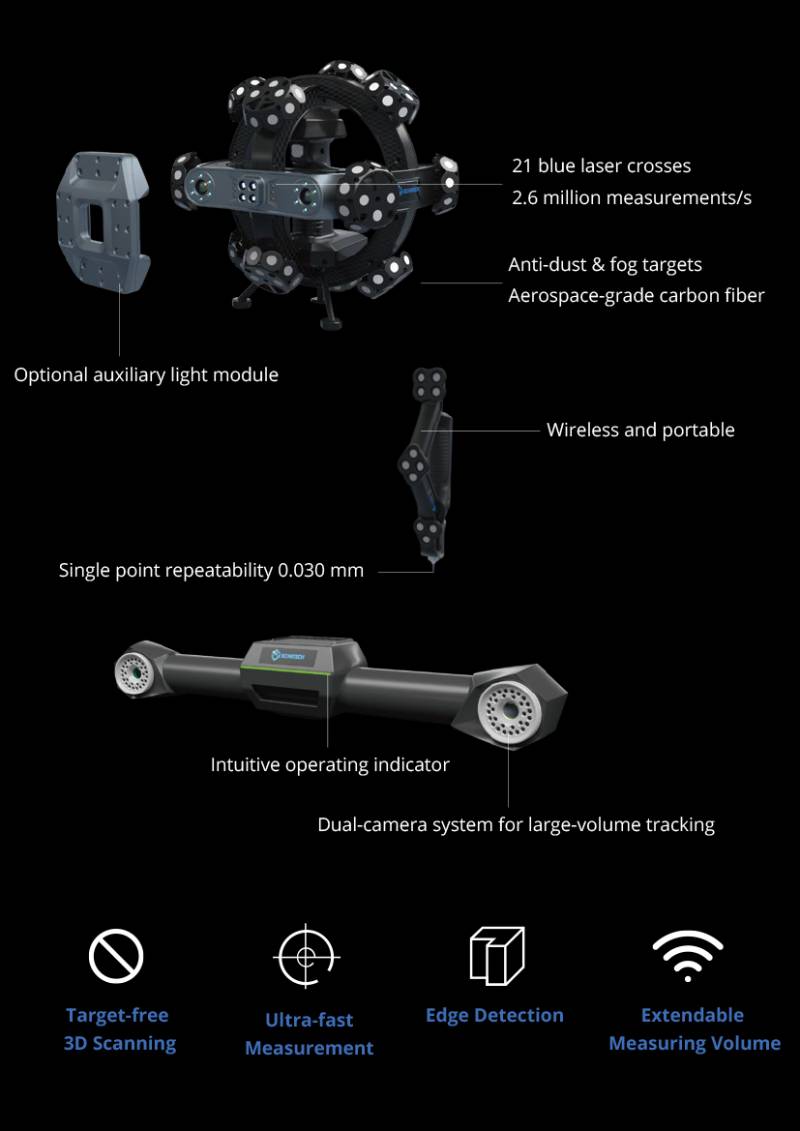

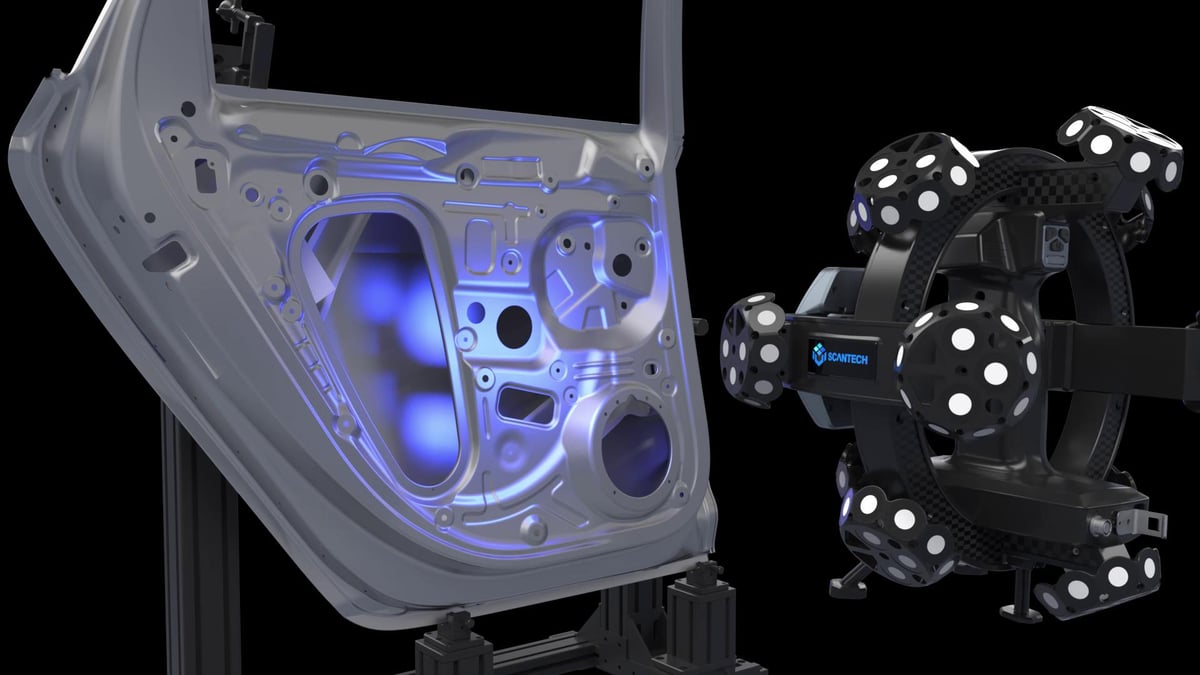

Engineered with intelligent optical tracking measurement and high-resolution cameras, TrackScan-P can precisely measure parts without requiring reference targets. This 3D measurement system, which consists of a portable 3D scanner and an optical tracker called E-Track, is well suited for 3D scanning large-scale objects. It can be widely applied for several projects, including quality control, product development, reverse engineering, and limitless applications in aerospace, automotive, transportation, and other fields.

By combining this 3D measurement system with additional modules, the capabilities of the TrackScan-P 550 can extend to even more applications. For example, it can be paired with an auxiliary light module to inspect circles, grooves, and machined holes of stamping parts. With the portable T-Probe accessory, users can capture precise contact measurements for edges, circles, and grooves. When mounted onto a robot arm, the TrackScan-P measurement system is an optimal choice for intelligent and fully automated 3D inspection.

TrackScan-P Offers Optical Tracking for Instant 3D Scanning

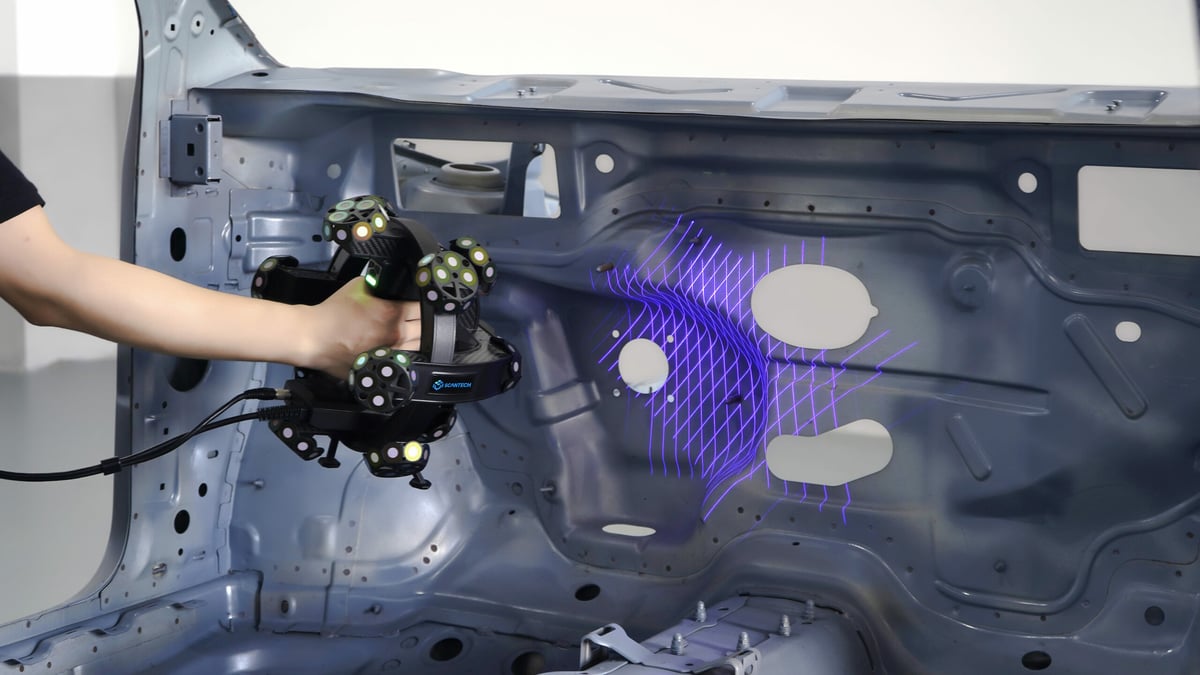

TrackScan-P 3D system’s optical tracking allows users to start scanning instantly without having to use reference targets. It is fully portable and is extremely easy to use, requiring just a few clicks to operate. This intuitive operation significantly improves overall efficiency and decreasing costs for the end-user.

Unrivaled Speed & Details

By offering multiple working modes that users can seamlessly switch between, the TrackScan fits different scanning situations. These different modes fit different purposes, ranging from an accuracy of up to 0.025 mm to an ultra-fast measurement rate of up to 2,600,000 measurements/s. TrackScan-P is equipped with seven parallel blue laser lines that help capture high details. Single blue laser line are utilized to collect 3D data from deep crevices, holes, and other hard-to-reach areas.

Precise Edge Detection

The stand-out feature that makes the TrackScan-P a next-level measurement system is the instant edge detection. With this function, users can inspect circles, grooves, and machined holes within stamping parts in various finishes right on the site. Moreover, this feature allows these parts to be fully measured and scanned without having to utilize the original CAD models.

Efficient edge detection is included via a gray value measurement and optional auxiliary light module. You can enjoy high-quality measurement results with high accuracy and repeatability, even with specific hole positions and diameters.

Strong Adaptability

Made from aerospace-grade materials, the TrackScan-P 550 is both sturdy and reliable. It also boasts a strong anti-interference capability that enables smooth operation regardless of vibrations or thermal variations from the external environment. Therefore, users can use it anywhere on the shop floor – no limitations. With its self-developed advanced algorithm, TrackScan is also highly capable of capturing 3D data from reflective and dark surfaces.

Extendable Applications

The TrackScan-P optical 3D measurement system can be integrated with Scantech’s other product offerings to further cater to different measurement needs.

For instance, when 3D scanning large-scale objects, the system’s measurement range can be dynamically extended by adding more E-Tracks

It can also be paired with a portable CMM T-Probe (optional with different sizes) to probe inaccessible areas such as holes and hidden points. This contact measurement probe can ensure precise results with high single-point repeatability of 0.030 mm.

When integrated with Scantech’s wireless communication link, called AirGo Pro, the measurement system can leverage free and mobile 3D scanning functionality.

TrackScan-P 550 can be mounted on a robotic arm to form AutoScan-T, an automated 3D measurement system best-suited for efficient batch measurement.

The E-Track accessory can also be combined with path planning software for intelligent robotic path planning and guiding.

All in all, with the new TrackScan-P 550 and Scantech’s wide range of additional products, professionals users have more flexibility than ever to capture precise and highly accurate 3D data from parts and objects of all shapes, sizes, and surfaces.

About Scantech

Scantech is one of the first high-tech companies to start research and development in handheld 3D visual measurement devices. Scantech products are sold to more than 60 countries and regions, serving over 5000 enterprises. Contact ScanTech to learn more: info@3d-scantech.com