Scantech, a leading expert in developing, manufacturing, and sales of high-tech 3D scanners, has released the latest version of its compact and handheld 3D scanner, SIMSCAN. This upgraded 3D scanner aims to set a new standard in metrology, boasting a palm-sized structure, high scanning efficiency, low power consumption, and an accuracy of up to 0.020 mm.

Leveraging constant dedication and collaborative work, Scantech engineers were able to increase the 3D scanning efficiency of SIMSCAN by 40%, while also reducing power consumption by 20% compared to its previous version.

SIMSCAN 3D Laser Scanner Combines Efficiency and Potability

SIMSCAN is calibrated according to JJF 1951 specification and VDI/VDE 2634 Part 3 standard. SIMSCAN-series 3D scanners will be assigned with fully traceable and internationally recognized accuracy certifications. Due to its compact size, simple operation, and robust performance, it is poised to become a disruptive professional 3D scanner among others in its class. Its cutting-edge design also won itself a German Red Dot Award and China Design Silver Award.

Designed in a compact size, SIMSCAN enables a smooth and convenient 3D scanning experience. Powered by 3D blue laser scanning technology, the device is ideal for scanning narrow spaces, overcoming common environmental restrictions. SIMSCAN is highly portable, allowing users to carry it around and conduct on-site 3D scanning for parts that come in different sizes and finishes.

The new SIMSCAN laser scanner features 42 lasers lines, further enhancing the scanning efficiency. In terms of measurement, it boasts a higher level of accuracy and repeatability.

It’s also engineered for long-last, consistent use. For instance, the instrument will not result in excessive heat buildup. To ensure the reliability of the 3D scanner, its calibration board is made of aerospace-grade carbon fiber, which is more resistant to impact and other stresses.

Find out what new features and benefits the upgraded SIMSCAN has to offer.

SIMSCAN Offers Single-Handed Control

SIMSCAN’s full-metal design provides sturdy protection and ensures extraordinary durability. Weighing only 570 g and boasting compact dimensions of 203 × 80 × 44 mm, SIMSCAN’s portability brings unparalleled simpleness for scanning anything with one hand.

Remarkable Portability

SIMSCAN boasts a compact size and excellent portability. Whether users need to scan around narrow spaces or underneath large-scale objects, SIMSCAN portable 3D scanner can conduct 3D measurement anywhere and anytime. When paired with AirGo Pro, its wireless communication link, it supports mobile 3D scanning and data viewing for truly flexible, reliable, and effective measurement experiences.

Narrow-Space Measuring Booster

Compared with other 3D scanners, SIMSCAN offers a much shorter camera distance of 130 mm, which forms a steeper view angle to 3D scan narrow spaces. Therefore, SIMSCAN is more capable of capturing accurate and complete data in hard-to-reach areas, such as deep grooves, and ensures that users capture full-field data from the object.

Detail, Everywhere, Anywhere

With its built-in HD cameras and three scanning modes, SIMSCAN is capable of high-precision scanning with an accuracy up to 0.020 mm. It can accurately capture the 3D data of objects with complex surfaces or in confined areas.

Smoother 3D Experience

SIMSCAN can 3D scan objects with a rate up to 2.8 million measurement per second. This rapid speed is made possible by its sophisticated algorithm and a camera frame rate that is higher than most of its competitors. It is designed to offer users a smoother and more efficient 3D digitizing experience.

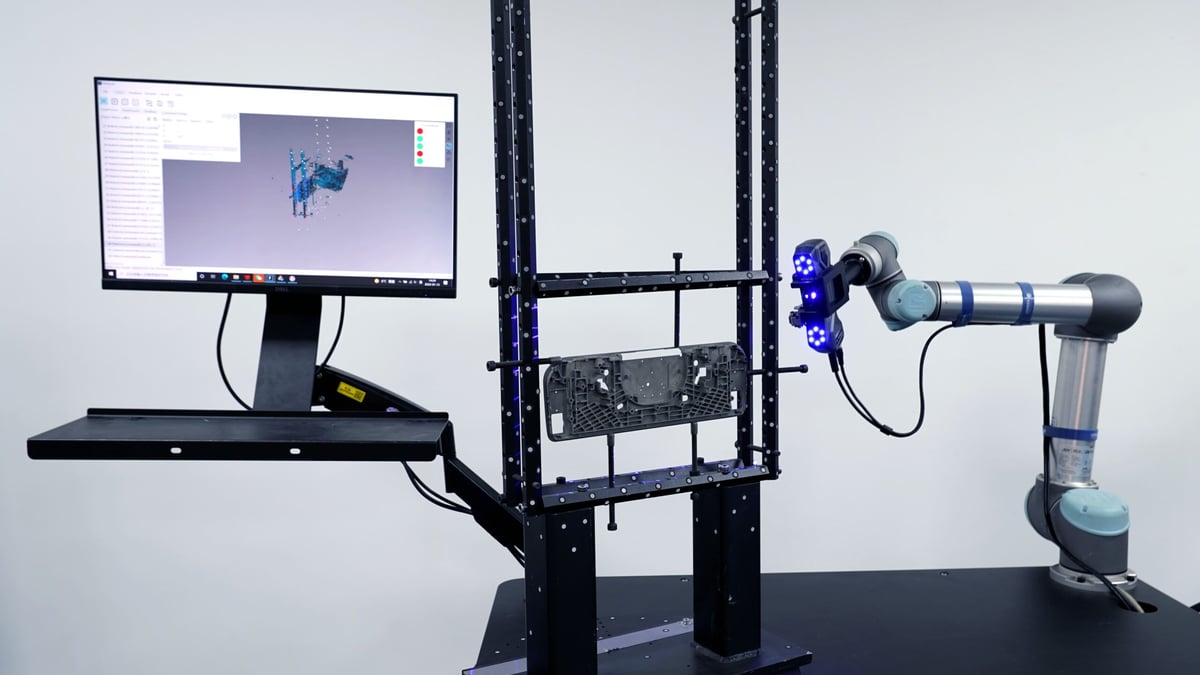

Automated 3D Measurement

SIMSCAN can be paired with Scantech’s automated 3D measurement system to achieve non-stop measurements. Automated high-batch measurement overcomes the limitation of traditional methods, and it significantly improves efficiency for all stages of manufacturing.

What Can SIMSCAN Do? Examples of Applications

Precise 3D Data to Ensure Flight Safety

SIMSCAN is flexible and efficient enough to acquire accurate 3D data of aircraft, including curved surface and dead corners. This high accuracy is helpful in examining the whole craft, significantly reducing maintenance downtime.

3D Visualization for Car Customization

Engineers and designers can use the compact SIMSCAN to efficiently obtain complete 3D data of automotive parts. With 3D data ready for design, users can customize and modify cars at will. It is an ideal solution for the popular personalized automobile market.

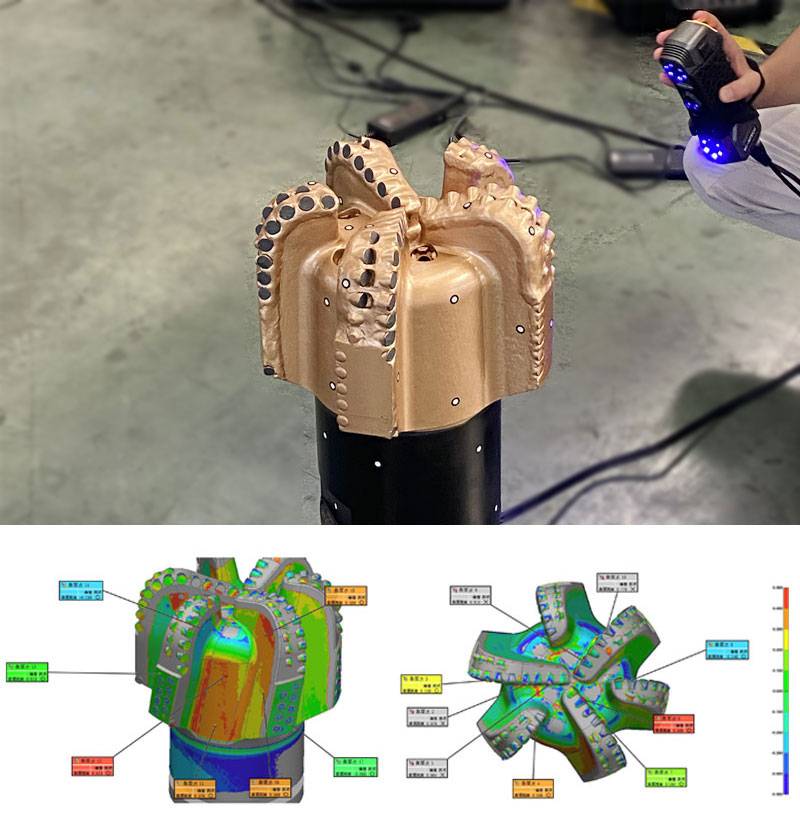

3D Inspection to Aid in Energy Exploitation

SIMSCAN has been used to 3D scan and inspect a diamond drill bit used for oil drilling. It helps to inspect the shape of matrix and the position of the inlay.

Efficient Measurement for Medical Field

SIMSCAN can scan precise medical products with highly reflective surfaces for reverse engineering, medical simulation, measurement analysis, and more.

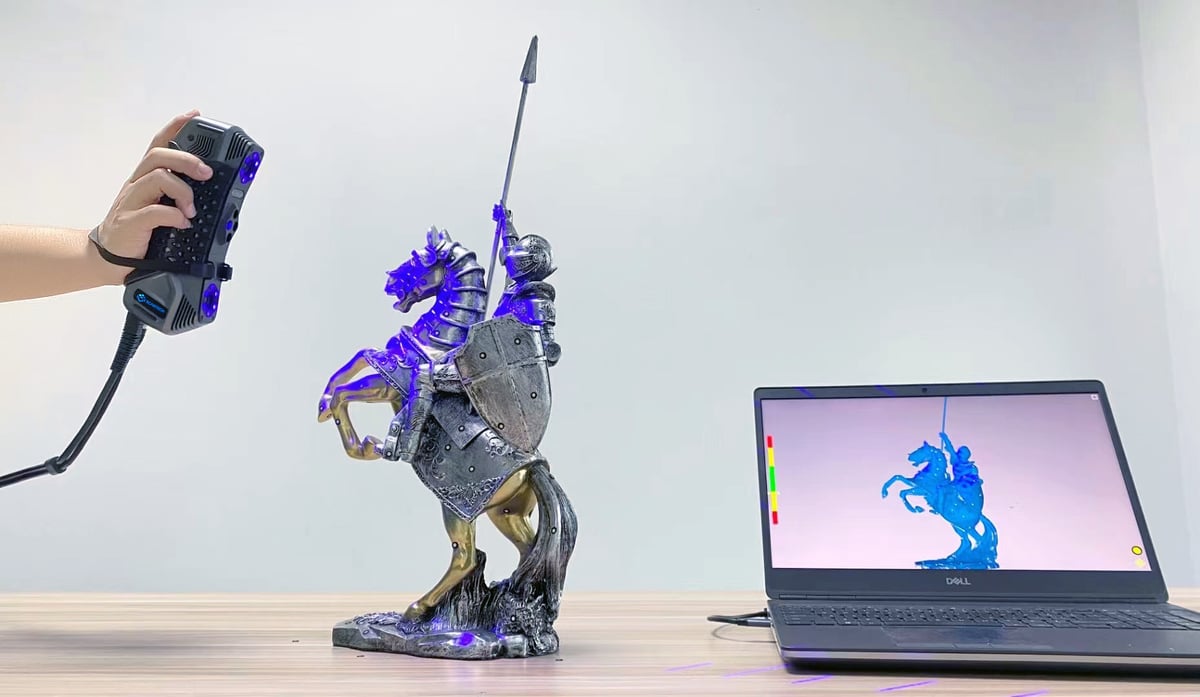

3D Reconstruction for Art Design

This cost-effective 3D scanner can be utilized to capture 3D data of existing products to serve as an inspiration for art design. Users can express the intent of their design based on the original version without having to start from scratch. It also provides a way for designers to validate every pattern, mold, and part during the product development process.

About Scantech

Scantech is one of the earliest high-tech companies starting to research and develop handheld 3D visual measurement devices worldwide. Our products are sold to more than 60 countries and regions, serving over 5000 enterprises. Contact us to learn more. (info@3d-scantech.com)